We work

Acid-resistant threaded parts and nipples

Acid-resistant threaded pipe fittings are very popular in industrial and construction applications where corrosive substances or processes are handled. These pipe fittings are made of a very durable material, acid-resistant AISI 316 steel, which offers excellent resistance against corrosion, oxidation, mechanical stress and temperature fluctuations.

Acid-resistant threaded pipe fittings are commonly available in a variety of shapes and sizes, making them extremely versatile and suitable for a wide range of applications. These pipe fittings include a variety of connections and shapes, such as threaded connections, welds, connections, adapters, and bends. In our Mittaletku, you can find almost all variations of threaded parts.

The manufacturing process of threaded pipe parts includes several steps, the most important of which are material selection, pipe design and manufacturing method. The commonly used material is acid-resistant or stainless steel, which is very durable and suitable for many uses. In terms of design, the threaded pipe parts can be made straight or curved, in which case the choice depends on the application and the placement of the pipe.

Manufacturing methods may also vary depending on the intended use. For example, larger pipes and constrictions can be made by welding several smaller parts together, while smaller pipes can be made by cold forming. In addition, there are other manufacturing methods, such as turning, which may be the optimal choice for manufacturing certain pipe parts.

Acid-resistant threaded pipe fittings are very popular in many industries where corrosion resistance is an important factor. This may include the oil and gas industry, chemical, pharmaceutical and food manufacturing, water supply and paper industries. These tubes are extremely durable, making them an excellent choice for harsh conditions and long-term use.

In addition, the easy installation and connections of threaded pipe fittings make them very practical in many applications. Sealing glue should be used in the connections of threaded parts, which above all lubricates the thread during the installation phase to prevent cutting.

Author

Toni Mielikainen

CEO

Mittaletku

+358 400 292 874

[email protected]

Linkedin

Toni is perhaps Finland's most experienced hose master, whose hands have passed through hundreds of solutions for all domestic industries. More than 20 years of experience in hose and connector matters can be seen as expertise that both large production plants and small breweries benefit from.

We used these products

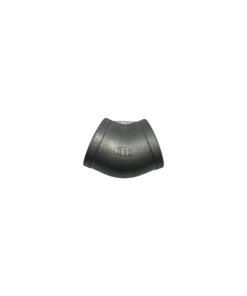

The HST elbow with internal threads is a high-quality connector designed specifically for the demanding needs of industry. This connector offers excellent durability and reliability, making it an ideal choice for long-term use. Made of durable material, it ensures safe and tight connections in various applications. Compatibility with multiple hose types makes it a versatile choice for various production environments. Applications Hydraulic systems, industrial process piping, fluid transfer applications Industries Mechanical engineering, chemical industry, food industry, marine industry Benefits The HST elbow with internal threads ensures reliable connections and enables easy installation in a wide range of systems. Its durable construction extends maintenance intervals and reduces downtime. Chemical and corrosion resistance This connector offers excellent protection against chemicals and corrosion, making it an ideal choice for harsh environments. Sealing The connector is preferably sealed on the thread with thread sealant, which also lubricates the thread during the fastening phase, preventing it from seizing. Acid-resistant material requires an activator to accompany the thread sealant. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

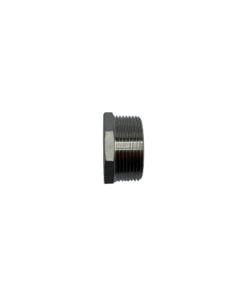

The HST cone plug is specifically designed for demanding industrial applications where sealing of hoses and piping is critical. Made from high-quality acid-resistant steel, this cone plug ensures excellent resistance to both pressure and temperature fluctuations. Applications industrial piping, hydraulic systems, pneumatic systems, chemical industry equipment Industries chemical industry, oil and gas industry, food industry, pharmaceutical industry Benefits The HST cone plug offers excellent sealing and durability, increasing system reliability and reducing maintenance costs. Its easy installation and removal saves time and effort. Risks If installed incorrectly, the cone plug can cause leaks and damage the system. It is important to ensure that the cone plug is the correct size and properly tightened. Chemical and corrosion resistance The HST cone plug offers excellent resistance to a wide range of chemicals and corrosion, extending its service life in demanding conditions. Sealing The connector is preferably sealed on the thread with thread sealant, which also lubricates the thread during the fastening phase, preventing it from seizing. Acid-resistant material requires an activator to accompany the thread sealant. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

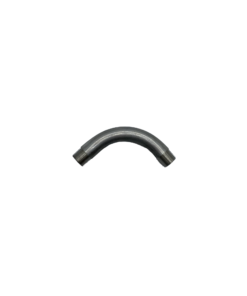

The HST threaded elbow is designed to provide a smooth elbow for industrial piping needs. Made from durable Aisi 316 steel, this elbow is built to withstand harsh conditions and long-term use. Its threaded design ensures easy installation and a tight connection, reducing the risk of leaks and improving the efficiency of your piping. Whether it's for maintenance of existing piping or installing new systems, this elbow is a reliable choice. Applications Water supply systems, gas pipelines, industrial fluid transportation, oil processing Industries Chemical industry, oil and gas industry, food industry, water supply Benefits HST threaded pipe elbow offers excellent durability and corrosion resistance, which extends the life of pipelines and reduces the need for maintenance. Chemical and corrosion resistance High-quality HST steel ensures excellent chemical and corrosion resistance, making the product ideal for challenging environments. Sealing The connector is preferably sealed on the thread with thread sealant, which also lubricates the thread during the fastening phase, preventing it from seizing. Acid-resistant material requires an activator to accompany the thread sealant. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

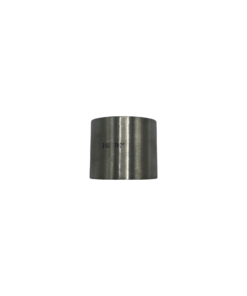

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar