Register as a customer to see prices, stock status and order from our online store.

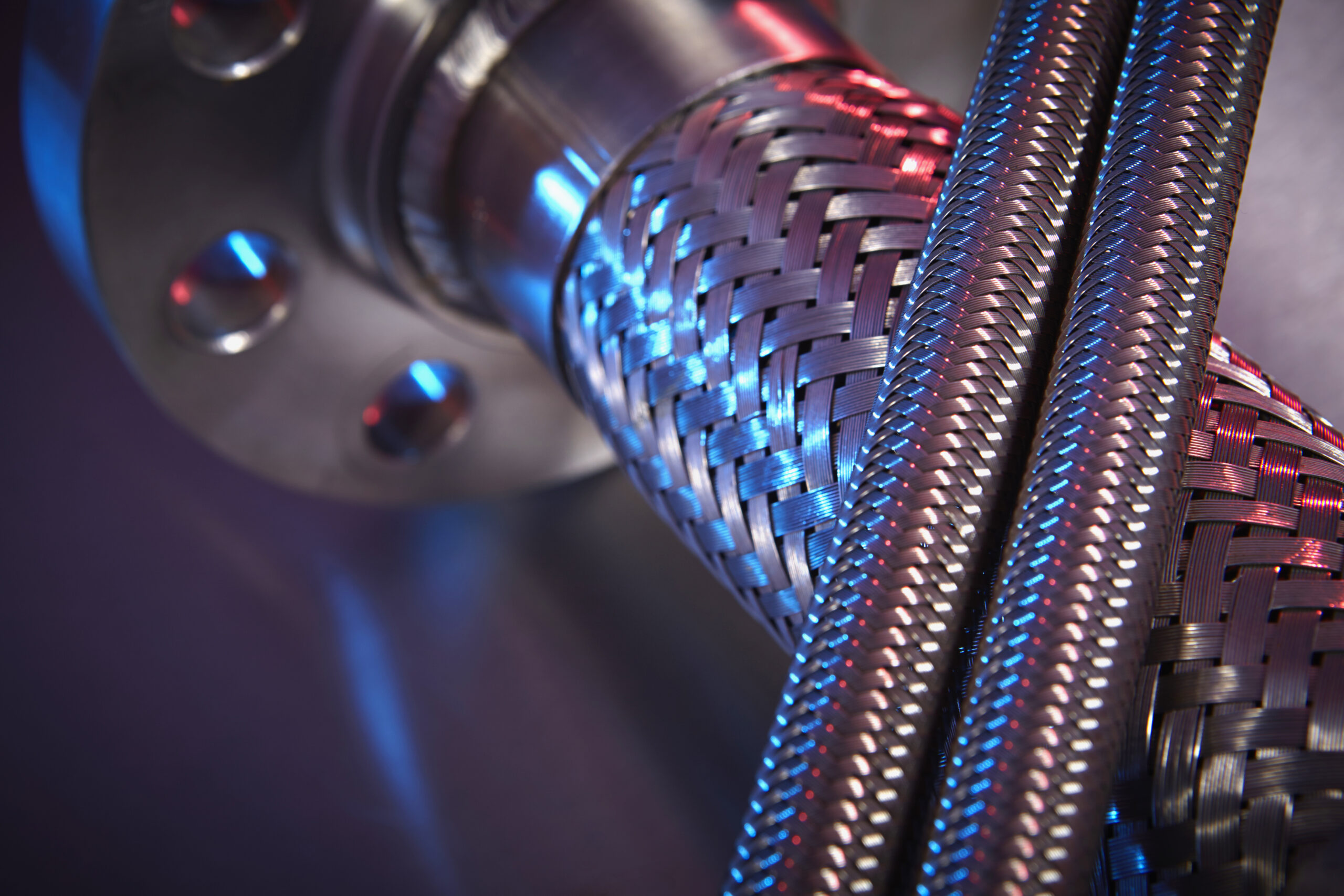

Composite hose chemical 10 bar black

0,00 € VAT 0%VAT 25.5%

Composite hose chemical 10 bar black is designed for the transfer of chemicals to withstand demanding industrial conditions. This black hose offers excellent performance and durability, especially when handling aggressive chemicals. The hose is designed to withstand an operating pressure of up to 10 bar, making it a reliable choice for a wide range of chemical transfer applications.

Applications

Transfer of chemicals, industrial process lines, loading and unloading of tankers.

Industries

Chemical industry, petrochemical industry, refineries, production plants.

Benefits

The hose offers high chemical resistance and a long service life, which reduces the need for maintenance and downtime.

Risks

Improper use or overuse can cause damage to the hose, which can lead to leaks or outages.

Adapters

Compatible with standard chemical fittings such as camlock and screw fittings.

Chemical resistance

Suitable for a wide range of chemicals including acids, bases and solvents.

Operating temperatures

-20°C to +80°C

Operating pressure classes

10 bar / 30 bar

Certificates and classes

EN 13765, ISO 9001

Act quickly and ensure your chemical transfer is safe and efficient by using this high quality composite hose. Request a quote today!

Do you want to know if the composite hose chemical 10 bar black is suitable for your needs? You will get a quick answer by calling, by e-mail mixed in chat.

You can order all hoses from us by the meter in the quantity you want or directly as a whole coil.

Register as a customer to see prices, stock status and order from our online store.

Composite hose chemical 10 bar black

Request a quote for the product you want easily by pressing the button below. We will reply to you with an offer within two hours. Do you need help finding the right product? Ask in the chat.

Composite hose chemical 10 bar black is designed for the transfer of chemicals to withstand demanding industrial conditions. This black hose offers excellent performance and durability, especially when handling aggressive chemicals. The hose is designed to withstand an operating pressure of up to 10 bar, making it a reliable choice for a wide range of chemical transfer applications.

Applications

Transfer of chemicals, industrial process lines, loading and unloading of tankers.

Industries

Chemical industry, petrochemical industry, refineries, production plants.

Benefits

The hose offers high chemical resistance and a long service life, which reduces the need for maintenance and downtime.

Risks

Improper use or overuse can cause damage to the hose, which can lead to leaks or outages.

Adapters

Compatible with standard chemical fittings such as camlock and screw fittings.

Chemical resistance

Suitable for a wide range of chemicals including acids, bases and solvents.

Operating temperatures

-20°C to +80°C

Operating pressure classes

10 bar / 30 bar

Certificates and classes

EN 13765, ISO 9001

Act quickly and ensure your chemical transfer is safe and efficient by using this high quality composite hose. Request a quote today!

Do you want to know if the composite hose chemical 10 bar black is suitable for your needs? You will get a quick answer by calling, by e-mail mixed in chat.

Products

| SKU | Size | Working pressure | Burst pressure | Bending radius | Weight kg/m | Coil | DN | Material | Delivery time | Ask for Quote |

|---|---|---|---|---|---|---|---|---|---|---|

| SKU: MCB10-038 | Size: 38mm / 1 1/2" | Working pressure: 10.5 bar | Burst pressure: 52 bar | Bending radius: 140 mm | Weight kg/m: 1,70 | Coil: 30 | DN: DN38 | Material: PP | Delivery time: 1-2 weeks | Ask for Quote |

| SKU: MCB10-051 | Size: 51 mm / 2" | Working pressure: 10.5 bar | Burst pressure: 52 bar | Bending radius: 180 mm | Weight kg/m: 1,80 | Coil: 30 | DN: DN50 | Material: PP | Delivery time: 1-2 weeks | Ask for Quote |

| SKU: MCB10-063 | Size: 63 mm / 2 1/2" | Working pressure: 10.5 bar | Burst pressure: 52 bar | Bending radius: 203 mm | Weight kg/m: 2,90 | Coil: 30 | DN: DN65 | Material: PP | Delivery time: 1-2 weeks | Ask for Quote |

| SKU: MCB10-076 | Size: 76 mm / 3" | Working pressure: 10.5 bar | Burst pressure: 52 bar | Bending radius: 274 mm | Weight kg/m: 3,50 | Coil: 30 | DN: DN76 | Material: PP | Delivery time: 1-2 weeks | Ask for Quote |

| SKU: MCB10-102 | Size: 102mm / 4" | Working pressure: 10.5 bar | Burst pressure: 52 bar | Bending radius: 381 mm | Weight kg/m: 5,50 | Coil: 30 | DN: DN100 | Material: PP | Delivery time: 1-2 weeks | Ask for Quote |

| SKU: MCB10-252 | Size: 252 mm / 10" | Working pressure: 10.5 bar | Burst pressure: 52 bar | Bending radius: 914 mm | Weight kg/m: 26,70 | Coil: 30 | DN: DN252 | Material: PP | Delivery time: 1-2 weeks | Ask for Quote |

| SKU: MCB10-025 | Size: 1" | Working pressure: 10.5 bar | Burst pressure: 52.5 | Bending radius: 122 mm | Weight kg/m: 0,95 | Coil: 20 | DN: - | Material: - | Delivery time: - | Ask for Quote |

Take advantage of these too

If you want to be sure of the compatibility of the hose you use with different chemicals, or if you want to know the thread or flange size of the connector, you can download guides for yourself below.

General

Chemical resistance table

With the help of the chemical resistance table, you can find out the compatibility of commonly used hoses with different chemicals easily and quickly.

AISI316

Chemical resistance table

With the chemical resistance table of acid-resistant products, you can find out the compatibility with different chemicals.

Plastic hose

Chemical resistance table

With the chemical resistance table of acid-resistant products, you can find out the compatibility with different chemicals.

General connector thread table

Do you want to find out the exact size of the connectors so that you can order exactly the right connector for your needs?

Flange dimensioning table

You can easily find out the size and standard of the flange with the help of the flange measurement table.

Always remember to consult hose experts to be absolutely sure of chemical compatibility!

Thread size lost?

Check out the spiral tables - you can easily download them for yourself as well.

Our service

As experts, we offer a wide range

a selection of different hoses for maintenance and service

related services.

Undone?

Our plumbers help with all questions quickly in the chat and through these contact details.

How do the different hoses work? What should be taken into account?

Take a look at the articles written by our hose masters about the selection, use and maintenance of different hose types. You will get valuable information on various topics that affect the selection of hoses.