Uncategorized, Chemical hose, Composite hose, Text ready

Composite hose is suitable for many different industries.

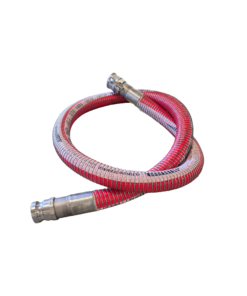

Composite hoses are a versatile and reliable solution for various industrial needs. Their unique structure and materials make them suitable for many different industries. Whether it is the chemical industry, oil and gas industry, energy production, food industry, automotive industry, water treatment, pharmaceutical industry or agriculture, composite hoses offer durability, flexibility and longevity for Finnish conditions.

Their areas of application and possibilities are almost limitless, and with this article I will explain in more detail how composite hoses can benefit different industries and what kind of top advantages they offer.

Finnish industry's credit line

In the industrial sector, composite hoses have proven to be very versatile and effective for a wide range of applications. The development of industry has greatly benefited from the use of these hoses. The hoses in question are well suited to the frosty conditions in Finland and are therefore also used as car unloading and loading hoses.

Composite hoses offer a solution that meets both industry needs and environmental concerns. These hoses are manufactured using a combination of materials such as polypropylene, polyethylene, PTFE, ECTFE and are reinforced with steel spirals on the outside and inside. This unique construction allows composite hoses to be used in extreme temperatures. The construction allows the hose to be manufactured to withstand harsh chemicals without losing its flexibility.

In industry, composite hoses are used for various purposes, such as the transfer of liquid substances. They are commonly used in industry and for the transfer of gases in various industrial sectors, such as the oil and gas industry, the chemical industry, the pharmaceutical industry and the food industry. The versatility of composite hoses makes them suitable for handling a wide range of substances, including acids, bases, solvents and hydrocarbons.

The 100% sure choice for the chemical industry

The chemical industry benefits greatly from the use of composite hoses due to their versatile and durable nature. Chemical processing requires the transport of a variety of chemicals, and composite hoses offer a reliable solution for this task. These hoses are manufactured from multiple layers of materials, such as polyamide, Teflon, fiberglass and stainless steel, which provide excellent resistance to a wide range of chemicals. The way the hose is manufactured allows the use of Teflon as the inner membrane of the hose, which in turn gives it a chemical resistance of almost 100%.

Industrial safety is of paramount importance in the chemical industry, and the use of composite hoses contributes to ensuring a safer working environment. These hoses are designed to be lightweight, highly flexible and easy to use, allowing for efficient and safe use. In addition, composite hoses are equipped with various safety features, such as grounding wires, which further enhance their safety performance.

The chemical industry can rely on composite hoses to efficiently and safely transfer chemicals during the production process. These hoses not only offer durability and versatility, but also contribute to industry safety standards. With their exceptional chemical resistance and advanced safety features, composite hoses are an indispensable tool in the chemical processing industry.

The best hose for oil and gas transfer

Composite hoses are also widely used in the oil and gas industry due to their exceptional performance and reliability.

In recent years, there has been a growing focus on reducing the environmental footprint of the oil and gas industry. Organizations are implementing stricter regulations and adopting more sustainable practices to reduce the industry’s impact on the environment. Composite hoses have emerged as an innovative solution to address these challenges.

Composite hoses are resistant to corrosion, chemicals and extreme temperatures, making them suitable for the harsh conditions of the oil and gas industry. They are also lightweight and flexible, facilitating the efficient and safe transport of oil and gas.

Ship unloading credit hose

The marine industry and shipping industry require products that are not only strong but also able to withstand the harsh sea conditions in ports. This sector encompasses a wide range of operations, such as ship unloading at port terminals. The durability and performance of hoses is of utmost importance as it directly impacts the safety and efficiency of operations carried out at sea.

Innovations in the marine industry have led to the development of composite hoses, specifically designed to meet the demanding requirements of this industry. Made from composite materials such as fiberglass and synthetic polymers, these hoses offer excellent resistance to corrosion, chemicals and extreme temperatures. They are lightweight yet extremely strong, making them ideal for applications in marine environments.

In addition, these composite hoses are flexible, allowing for easy installation even in tight spaces. Thanks to their advanced design and construction, composite hoses contribute to the efficiency and safety of the entire marine industry operations.

Five good reasons to choose composite hose

Durable composite hoses for tanker unloading represent a significant technological advancement in the transportation industry. As an expert, I would like to highlight a few important aspects that make these hoses an excellent choice for tanker unloading.

-

Durability and Reliability: Durable composite hoses are specifically designed to withstand the extreme conditions associated with discharges. Their materials and construction allow them to be used for long periods of time without significant damage or wear. This increases reliability and reduces the need for regular maintenance.

-

Lightweight and flexible construction: Composite hoses are significantly lighter than traditional rubber hoses, making them easier to handle and install. Their flexibility allows for smooth unloading and minimizes tension that can cause damage to the hoses or the unloading process. They are easy to move due to their construction.

-

Corrosion resistance: One important advantage of composite hoses is their corrosion resistance. They do not react with chemicals or rust, making them an ideal choice for transporting fluids such as various chemicals or oil.

-

Efficiency and safety: Composite hoses are designed with flow efficiency and safety in mind. Their inner surface is durable, which is especially important when transporting sensitive or hazardous materials.

-

Environmental friendliness: In many cases, composite hoses are more environmentally friendly than traditional alternatives, as they can reduce emissions and waste.

In conclusion, from the experts' point of view, composite hoses are an excellent choice for tanker unloading. They combine durability, efficiency and safety, making them an attractive option for many different industries.

Conclusion

The versatility of composite hoses makes them suitable for various industries such as industrial, chemical, oil and gas, energy, food, automotive, water treatment, pharmaceutical and agricultural. Their ability to withstand harsh conditions and transport a wide range of media makes them an essential part of these industries. Composite hoses provide a reliable and efficient solution for fluid transfer in a variety of applications.

You can get composite hoses from us with fast delivery

Composite hose 2" male female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible construction makes handling and installation easy. Acid-resistant camlocks ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose has a Teflon membrane on the inside and acid-resistant connectors. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female saflok is designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" female saflok is designed to withstand demanding industrial conditions where reliability and chemical resistance are key. Its durable and flexible construction ensures easy connection and quick installation, making it an ideal choice for professionals. The hose is equipped with 2" camlock fittings, which allow for smooth connection to various systems. The Teflon inner surface ensures excellent chemical resistance, expanding the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Teflon coating inside the hose ensures excellent chemical resistance. Acid-resistant safety locking Saflok cam lever connector ensures the safety of the pressurized hose. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 3" male threads are designed for the demanding needs of industrial chemical transfer, offering excellent durability and versatility in various conditions. This hose is made of high-quality materials, ensuring long service life and reliable performance. The 3 inch composite hose with acid-resistant male threads is easy to connect and install, making it an ideal choice for industrial professionals. The Teflon inner surface of the hose provides a wide range of chemical resistance. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The composite construction offers lightness and flexibility, making the hose easy to handle and install. The high-quality materials ensure excellent durability in demanding industrial environments. Risks Although the hose is designed to withstand a variety of chemicals, improper or excessive pressure can cause damage. It is important to ensure that the hose is installed correctly and used within the recommended operating conditions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose is highly resistant to a wide range of chemicals, making it ideal for demanding industrial applications. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes Hoses are manufactured and tested according to EN 13765 - IMO IBC code.

Composite hose 2" male camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Teflon hose 5 bar is a durable and high-quality choice that offers reliability and longevity for industrial needs. The inner material of the hose is PTFE / Teflon and the outer material is PVC-coated polyester. The hose can withstand a pressure of 5 bar and its temperature range is -30 °C to +100 °C. Applications Teflon hose 5 bar is perfectly suited for use in petrochemicals, ports and ship to ship and ship to shore operations. Industries The hose is widely used in various industries, such as the petrochemical industry, ports and ships. Benefits Teflon hose 5 bar offers durability and reliability, which reduces maintenance and replacement needs. Risks Misuse or careless maintenance of the hose can lead to its damage. For this reason, it is important to observe proper use and maintenance. Adapters The Teflon hose 5 bar is compatible with various connectors, which allows it to be integrated into a wide range of systems. Chemical resistance Teflon hose 5 bar is made to withstand various chemicals, offering reliability and longevity. Certificates and classes The hose meets EN 13766: 2010, IMO, ICG codes. If you are looking for a durable and reliable hose for industrial needs, Teflon hose 5 bar is an excellent choice. Contact our experts and request a quote today!

Multioil Composite hose 14 bar is specially designed for oil, fuel, petrol, paraffin and jet fuel. This blue hose combines versatility with excellent chemical resistance, making it an ideal solution for many industrial needs. Several sizes and colors are available, and our experts are happy to help you choose the right size. Applications: Ports, Petrochemical processes, Tankers. Industries: Oil and petrochemical industry, Transportation industry, Industrial service and maintenance. Benefits: Provides exceptional resistance to chemical agents, which extends the life of the hose. A versatile selection of sizes and colors enable customized solutions for different applications. Risks: As experts in composite hoses, we emphasize the importance of correct use and maintenance for the hoses' longevity. If used incorrectly or poorly maintained, the hoses can be damaged prematurely. Adapters: Compatible connectors available in different types and sizes, optimally fit Multioil composite hoses. Chemical resistance: Designed to withstand many chemicals, including oils and fuels, making it an ideal choice for demanding industrial applications. Certificates and classes: Meet industry standards and norms, more details available on request. Do you want to hear more or request an offer? Contact us via chat or call us - we'll be happy to help!

Author

Toni Mielikainen

CEO

Mittaletku

+358 400 292 874

[email protected]

Linkedin

Toni is perhaps Finland's most experienced hose master, whose hands have passed through hundreds of solutions for all domestic industries. More than 20 years of experience in hose and connector matters can be seen as expertise that both large production plants and small breweries benefit from.