Hoses

Different hydraulic connector types and their differences

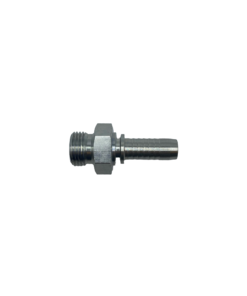

The DIN straight pipe fitting is the ideal solution for industrial piping needs, offering reliability and longevity. Designed to be compatible with DIN 2353 fittings, it ensures tight connections and easy installation. The heavy-duty design ensures excellent performance even when using rigid pipes. Available in a variety of sizes, finding the right size is easy. Applications Hydraulic systems, industrial piping, heavy machinery Industries Industry, mechanical engineering, energy sector Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing DIN 2353 dkos series connectors only seal against the body from their cone. This connector also includes a cutting ring and nut to ensure a successful connection. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The DIN elbow pipe joint is designed to provide a reliable and long-lasting solution for demanding industrial piping needs. This elbow fitting is compatible with DIN 2353 fittings, allowing for easy installation and ensuring tight connections. The heavy-duty construction ensures excellent performance and durability, even when using rigid pipes. Available in a range of sizes, it is easy to find the right option. Applications Hydraulic systems, industrial piping, heavy machinery Industries Industry, mechanical engineering, energy sector Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing DIN 2353 dkos series connectors only seal against the body from their cone. This connector also includes a cutting ring and nut to ensure a successful connection. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The DIN hose connector elbow dkos heavy series is designed to withstand demanding conditions in industry, providing a reliable solution for building hydraulic systems. Its seamless connection to DIN 2353 pipe fittings allows for strong and durable connections, even in rigid pipes. The heavy-duty design ensures longevity and excellent performance. The DKOS sealing ensures perfect tightness and efficient operation. Applications Hydraulic systems, industrial piping, heavy machinery Industries Industry, mechanical engineering, energy sector Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing DIN 2353 dkos series connectors only seal against the body with their cone. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The DIN hose connector elbow dkos heavy series is designed to withstand demanding industrial conditions and offers a reliable solution for building hydraulic systems. This connector series combines seamlessly with DIN 2353 pipe connectors, allowing for strong connections even to rigid pipes. The heavy series construction guarantees longevity and performance, and the DKOS sealing ensures excellent tightness. A wide range of connectors in different sizes is available, so there is a suitable option for all needs. Applications Hydraulic systems, industrial piping, heavy machinery Industries Industry, mechanical engineering, energy sector Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing DIN 2353 dkos series connectors only seal against the body with their cone. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The DKOS heavy-duty series of DIN hose fittings is designed to withstand demanding industrial conditions, providing a reliable solution for building hydraulic systems. This series of fittings seamlessly integrates with DIN 2353 pipe fittings, enabling strong connections even to rigid pipes. The heavy-duty series construction ensures longevity and performance, while the DKOS seal provides excellent tightness. The fittings are available in a wide range of sizes, so there is a suitable option for all needs. Applications Hydraulic systems, industrial piping, heavy machinery Industries Industry, mechanical engineering, energy sector Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing DIN 2353 dkos series connectors only seal against the body with their cone. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

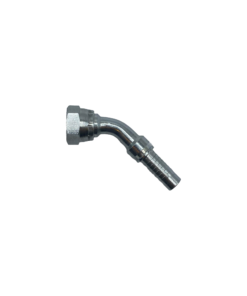

Din angle connector dkol light series is designed to enhance the operation of hydraulic systems at a 45 degree angle. This connector provides a durable and leak-proof solution in combination with DIN 2353 pipe connectors, enabling the construction of high-quality hydraulic systems. The hose connector is ideally suited for use with hard hydraulic pipes, offering a wide range of different connector options. This reliable connector has been developed for professionals who demand the best performance and easy installation. Applications Hydraulic systems, industrial piping, machinery and equipment maintenance Industries Industry, engineering, construction, energy sector Benefits This connector improves system reliability and reduces installation time. Its versatility ensures compatibility with various piping configurations. Chemical and corrosion resistance The connector is designed to withstand harsh chemical and corrosive environments, extending its service life. Sealing The DIN 2353 light series connector only seals its cone against the body. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The DIN hose connector angle dkol light series is designed to enhance the operation of hydraulic systems at a 45 degree angle. This connector provides a durable and leak-proof solution in combination with DIN 2353 pipe connectors, enabling the construction of high-quality hydraulic systems. The hose connector is ideally suited for use with hard hydraulic pipes, offering a wide range of different connector options. This reliable connector has been developed for professionals who demand the best performance and easy installation. Applications Hydraulic systems, industrial piping, machinery and equipment maintenance Industries Industry, engineering, construction, energy sector Benefits This connector improves system reliability and reduces installation time. Its versatility ensures compatibility with various piping configurations. Chemical and corrosion resistance The connector is designed to withstand harsh chemical and corrosive environments, extending its service life. Sealing The DIN 2353 light series connector only seals its cone against the body. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The external thread of the Bspt cone connector is designed for hydraulic hose assemblies. This product is made to withstand the challenging conditions of industry. The taper thread is well suited for quick couplings as well as cylinders and other connections where you want to get as far as possible with nipples. Applications Hydraulic systems, industrial equipment, hose installation and maintenance. Industries Industry, hydraulics, equipment manufacturing, maintenance and installation. Benefits The external thread of the Bspt cone connector offers a reliable and long-lasting solution for connecting hoses, reducing the need for maintenance and improving production efficiency. Risks Improperly installed or maintained, the connector can cause hose damage or leaks, emphasizing the importance of proper installation and maintenance. Adapters Compatible with many different hydraulic hoses. Chemical resistance Made to withstand the extreme conditions of industrial chemicals, providing reliability and longevity. Operating temperatures Temperatures required in hydraulic systems Operating pressure classes Hydraulic pressures. Certificates and classes DNV-GL, Bureau Veritas (BV), American Bureau of Shipping (ABS), EN 1474-II, EN 12434, EN 1474-III. If you need a reliable and durable solution for connecting hoses, the external thread of the Bspt cone connector is the right choice. Request a quote today.

Bsp tee fitting directional is a versatile and durable solution for all hydraulic systems. Made of high quality steel, this fitting allows for efficient and safe splitting of hydraulic lines. Bsp tee fitting is also known as R thread or pipe thread, making it one of the most common choices in industrial applications. This fitting series has been designed with special focus on durability and compatibility with different systems. Applications Hydraulic systems, fluid transfer networks, industrial distribution systems Industries Industry, manufacturing, engineering, water technology Benefits Bsp tee connector offers excellent durability and easy installation, enabling long-term use in demanding conditions. Its versatile compatibility with various systems makes it an ideal choice for many industrial applications. Chemical and corrosion resistance BSP tee fitting is designed to withstand a wide range of chemicals and corrosion, ensuring reliable performance in demanding environments. Sealing The connector has an R thread with a BSP seal. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The BSP forged angle 90° is a durable and reliable connector designed especially for industrial needs. This product provides an excellent solution for hose procurement and replacement and is compatible with a wide variety of hoses. Applications Hydraulic systems, industrial equipment, machine shops. Industries Industry, construction, machine shops. Benefits The BSP forged angle 90° offers a long-lasting and reliable solution for connecting hoses. It is easy to install and it withstands very high operating pressures. Risks Improper installation or maintenance may result in connector damage or leakage. Correct installation and maintenance are therefore very important. Adapters Compatible with many different hydraulic hoses. Chemical resistance Made to withstand industrial chemicals, BSP forged angle 90° offers a long-lasting and reliable solution. Operating pressure classes Hydraulic pressures. Contact our experts and request a quote for the BSP forged angle 90° connector. We offer comprehensive advice and make sure that you get a solution that suits your needs.

The BSP forged angle 90° is a durable and reliable connector designed especially for industrial needs. This product provides an excellent solution for hose procurement and replacement and is compatible with a wide variety of hoses. Applications Hydraulic systems, industrial equipment, machine shops. Industries Industry, construction, machine shops. Benefits The BSP forged angle 90° offers a long-lasting and reliable solution for connecting hoses. It is easy to install and it withstands very high operating pressures. Risks Improper installation or maintenance may result in connector damage or leakage. Correct installation and maintenance are therefore very important. Adapters Compatible with many different hydraulic hoses. Chemical resistance Made to withstand industrial chemicals, BSP forged angle 90° offers a long-lasting and reliable solution. Operating pressure classes Hydraulic pressures. Contact our experts and request a quote for the BSP forged angle 90° connector. We offer comprehensive advice and make sure that you get a solution that suits your needs.

BSP Reducing nipple solid is designed to ensure a seamless and reliable connection between hoses of different sizes for industrial needs. This durable and precisely manufactured connector is especially suitable for situations where a safe and leak-proof connection is required. Made of high-quality materials, it is highly resistant to corrosion and other environmental stresses. Its simple and efficient design ensures quick installation and long-lasting use. Applications Hydraulic systems, pneumatic applications, oil and gas equipment, chemical industry pipelines. Industries Industry, construction, maritime industry, chemical industry, energy sector. Benefits BSP Reducing nipple solid offers excellent durability and reliability, reducing maintenance and increasing system life. Ease of use and quick installation save time and reduce installation costs. Chemical and corrosion resistance The product is made of materials that are highly resistant to a variety of chemicals and corrosion, making it an ideal choice for demanding industrial environments. Sealing The connector has a straight R/BSP thread and requires a USIT ring to seal. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The BSP T-fitting with external threads is designed to provide an efficient and durable solution for industrial hose systems. This fitting is made of high-quality materials that ensure excellent durability and long service life. Its external thread allows for easy and quick installation, making it an ideal choice for a wide range of industrial applications. The BSP T-fitting is compatible with a wide range of hose types, increasing its versatility. Applications Industrial plants, power plants, chemical industry, oil and gas industry, food industry Industries Energy, chemistry, oil and gas, food, process industry Benefits The BSP T-fitting with external threads provides a reliable and leak-free connection, reducing maintenance costs and improving system efficiency. Its durable construction ensures longevity even in demanding conditions. Risks If installed incorrectly, the connector can cause leaks, which can lead to significant system failures. It is important to ensure proper installation and compatibility with the hoses being used. Hoses Compatible hoses: Hydraulic hoses, compressed air hoses, chemical hoses Chemical resistance The BSP T fitting is highly resistant to many chemicals used in industry, making it suitable for challenging environments. Operating temperatures -50 - +220°C Operating pressure classes 150bar / 450bar

BSP hose connector male thread is a high-quality hydraulic connector designed specifically for the demanding needs of industry. This connector is made to withstand heavy use and is also available in acid-resistant AISI 316 material, which improves its resistance to chemical environments. Its design allows for a reliable and durable connection, reducing the need for maintenance and replacement. BSP hose connector male thread meets several industry standards, ensuring high-quality performance. Applications Hydraulic systems, industrial plants, marine and offshore applications. Industries Industry, shipping, offshore industry. Benefits BSP hose connector male thread offers reliability and durability, reducing the need for hose maintenance and replacement. Chemical and corrosion resistance Made to withstand harsh chemical environments, ensuring longevity and reduced maintenance. Sealing The BSP connector seals against the mating part with its cone. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Bsp hose connector angle female thread is a high quality steel hydraulic hose connector, specially designed to be pressed onto hydraulic hoses. This 45 degree angle connector is ideal for tight spaces where flexibility and reliability are required. Its durable construction allows for long-term use in demanding industrial applications. We offer our customers the opportunity for customized solutions to meet different needs. Applications For machines, equipment Industries Industry, rolling stock Benefits The connector withstands high pressures, ensuring safe and efficient operation of the hydraulic system. Chemical and corrosion resistance Made to withstand extreme conditions such as chemicals and corrosion, ensuring a long service life. Sealing The BSP connector seals its cone to its counterpart. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The BSP double nipple male/female thread is designed specifically for hydraulic systems where its versatility comes into its own. Made from durable steel, this fitting converts an internal thread into an external thread, allowing for seamless connection of lines of different sizes. Known as R-thread or pipe thread, the nipple is a reliable partner in demanding industrial environments. Its ability to adapt to different thread types makes it an essential tool for professionals. Applications Hydraulic systems, industrial piping, machine and equipment connections Industries Industry, mechanical engineering, shipping, civil engineering Benefits The BSP double nipple male/female thread allows for quick conversion of thread types and line sizes, making it ideal for versatile use. Chemical and corrosion resistance The steel construction is highly resistant to many chemicals and is corrosion resistant, but compatibility must be checked before use. Sealing The BSP connector seals against the cone or flat surface with a sealing ring. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The Banjo coupling for hydraulic hose is designed to provide a reliable and durable solution for industrial needs. This high-quality coupling ensures excellent sealing with USIT seals or copper washers. It is ideal for use in various hydraulic systems where an efficient and long-lasting connection is required. The Banjo coupling is easy to install and offers excellent performance even in demanding conditions. Applications Hydraulic systems, industrial equipment, mechanical engineering, automotive industry Industries Industry, engineering, automotive, construction Benefits The banjo fitting offers excellent sealing and durability, reducing the risk of leaks and extending the life of the system. Risks Incorrectly installed or poor quality seals can weaken the tightness of the connection and cause leaks, which can lead to system malfunctions. Hoses Compatible hoses: SAE 100R1, SAE 100R2, EN 853 1SN, EN 853 2SN Chemical resistance The banjo fitting is highly resistant to most common hydraulic oils and chemicals, making it a versatile choice for various applications. Operating temperatures -40 - +120°C Operating pressure classes Hydraulic pressures.

WEO PLUG-IN Series 712 contains plugs with a 45° hose reel for single or double fabric hydraulic hose up to one inch.

The straight extension coupling light series is designed to provide a reliable and durable solution for hydraulic pipe extensions. This coupling requires a nut and a bead on both ends to make a successful connection. Available in a variety of sizes, it ensures versatile use in various applications. The coupling's heavy-duty pipe grip with mm threads makes it an excellent choice for industry. Applications Hydraulic systems, industrial piping, engineering industry, agricultural machinery Industries Mechanical industry, energy sector, agriculture, engineering industry Benefits The straight extension connector lightweight series offers easy installation and a diverse range of sizes, ensuring suitability for various applications. The durable construction and materials ensure longevity and reliability. Chemical and corrosion resistance The connector is highly resistant to a wide range of chemicals, making it suitable for demanding industrial environments. It protects against corrosion, which extends the connector's service life. Sealing The hydraulic pipe is sealed with a cutting ring and the hose connector with a cone in the connector. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The protective plug for Cejn 525 female coupling is designed to ensure the cleanliness of hydraulic systems and the functionality of quick couplings. This rubber protective plug provides effective protection against contaminants, extending the service life of the couplings and reducing the need for maintenance. It is specifically designed for use with Cejn 525 series female couplings, offering perfect compatibility and easy installation. The protective plug is an essential accessory for industrial professionals who want to ensure the reliable operation of their systems. Applications Hydraulic systems, industrial machinery, agricultural equipment, construction machinery Industries Industry, agriculture, construction, transportation Benefits The use of a rubber protection plug extends the service life of the connectors and ensures the cleanliness of the hydraulic systems. This significantly reduces maintenance and repair costs. Chemical and corrosion resistance The protective plug provides good protection against a variety of chemicals, reducing the risk of corrosion and ensuring long-term durability of the connectors.

WEO PLUG-IN Series 714 contains plugs with a 90-degree hose reel for single or double-weave hydraulic hose up to one inch.

WEO PLUG-IN Series 710 contains plugs with a straight hose reel for single or double fabric hydraulic hose up to one inch.

WEO PLUG nipple with external thread. A hole in the nipple for the plug of the WEO connector.

The Tulppa light series is specially designed for pressure blinding of hydraulic pipes in industrial applications. Made of high quality materials, this connector offers a reliable and durable solution for demanding conditions. Installation requires the use of a nut and a cutting ring, which ensures a tight and secure connection. Compatible with DIN 2353 standard pipes. Applications Hydraulic systems, pipe blinding, industrial applications, pressurized piping Industries Engineering industry, oil and gas industry, marine industry, energy sector Benefits The Tulppa lightweight series offers excellent corrosion resistance and easy installation, making it a reliable choice for demanding industrial applications. Risks If installed incorrectly, the connector can cause leaks, which can lead to pressure losses in the system and possible damage. Hoses Compatible with DIN 2353 standard connectors Chemical resistance The Tulppa lightweight series is resistant to most chemicals used in industry, making it a versatile choice for a variety of environments. Operating temperatures -40 - +200°C Operating pressure classes 315 bar / 630 bar Certificates and classes DIN 2353

The heavy-duty plug series is designed specifically for demanding industrial needs, where a reliable and durable solution is needed for blinding hydraulic pipelines. Made of high-quality materials, this connector withstands very high pressures and offers excellent durability. A nut and cutting ring are also required for installation, which ensure a tight and secure connection. The product is compatible with pipes according to DIN 2353. Applications Hydraulic piping, blinding of pressurized piping, maintenance and installation of industrial piping. Industries Industry, engineering, hydraulic systems, energy industry. Benefits The Tulppa heavy series offers excellent durability and reliability in high-pressure applications. Easy installation ensures quick commissioning and reduces downtime. Risks An incorrectly selected size or fitting can cause leaks or damage to the system. It is important to ensure the correct size fitting and any necessary accessories are used during installation. Hoses Compatible connectors: Connectors according to DIN 2353 standard. Chemical resistance The plug is designed to withstand commonly used hydraulic fluids and oils, making it a versatile choice for various industries. Operating temperatures -40 - +200°C Certificates and classes DIN 2353

Tractor quick coupler affordable male set of 5pcs is designed to make connecting and disconnecting tractor hoses faster and easier. This set includes five durable and reliable male couplers made of high-quality materials, providing excellent performance in demanding industrial conditions. The quick couplers are compatible with a wide range of hoses, making them versatile and practical for a variety of applications. These couplers save you time and effort, which improves work efficiency. Applications tractor hydraulic systems, agricultural machinery hose systems, industrial fluid transfer Industries agriculture, industry, construction Benefits Quick connectors provide quick and easy connection without tools, reducing maintenance downtime and improving efficiency. Chemical and corrosion resistance These connectors are designed to withstand a wide range of chemicals and prevent corrosion, which extends their service life and improves reliability. Sealing You should quickly seal the holes with a ring against the surface. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

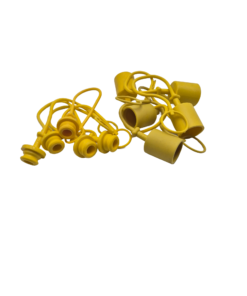

Tractor quick coupler protective cap 5pcs at a good price is a solution that effectively protects tractor quick couplers from dust and dirt, extending their service life. This protective cap is easy to install and remove, which makes it practical for daily use. The durable material ensures protection even in demanding conditions, and the package contains five protective caps, offering good value for money. Designed specifically for industrial needs, this protective cap is a reliable choice for professionals. Applications Tractors, agricultural machinery, industrial vehicles, construction machinery Industries Agriculture, construction, industry, logistics Benefits The protective cap reduces wear and contamination of the connectors, which extends their service life and ensures efficient operation. Chemical and corrosion resistance Designed to withstand common chemicals and environmental influences, the protective cap provides good protection against corrosion and chemical damage.

Tractor quick coupler protective cap 5pcs at a good price is a solution that effectively protects tractor quick couplers from dust and dirt, extending their service life. This protective cap is easy to install and remove, which makes it practical for daily use. The durable material ensures protection even in demanding conditions, and the package contains five protective caps, offering good value for money. Designed specifically for industrial needs, this protective cap is a reliable choice for professionals. Applications Tractors, agricultural machinery, industrial vehicles, construction machinery Industries Agriculture, construction, industry, logistics Benefits The protective cap reduces wear and contamination of the connectors, which extends their service life and ensures efficient operation. Chemical and corrosion resistance Designed to withstand common chemicals and environmental influences, the protective cap provides good protection against corrosion and chemical damage.

Tractor quick coupler protection set 5pcs at a good price provides effective protection for tractor quick couplers from dust and dirt, extending their service life. The protective caps and protective plug are easy to install and remove, making them practical for daily use. The durable material ensures protection in demanding conditions, and the pack of five offers excellent value for money. This protection set is designed specifically for the needs of industrial professionals. Applications Tractors, agricultural machinery, industrial vehicles, construction machinery Industries Agriculture, construction, industry, logistics Benefits The protective cap reduces wear and contamination of the connectors, which extends their service life and ensures efficient operation. Chemical and corrosion resistance Designed to withstand common chemicals and environmental influences, the protective cap provides good protection against corrosion and chemical damage. Sealing Silicone seals, rubber seals Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The Tractor Quick Coupler Seal Kit offers a complete solution for industrial applications requiring reliable and durable sealing. This high-quality kit is specifically designed for tractor quick couplers and ensures excellent performance and long service life. The seal kit includes all the necessary seals, made of durable material that prevents leaks and improves connection reliability. Easy to install, this kit is the ideal choice for professional use. Applications Tractor quick couplers, hydraulic systems, industrial applications Industries Agriculture, construction industry, logistics, engineering industry Benefits With the gasket kit, you ensure tight connections and prevent leaks, which reduces maintenance costs and improves system efficiency. Chemical and corrosion resistance The seals are made of materials that are resistant to some chemicals and oils, providing longevity in demanding environments.

The tractor quick coupler PUCH PULL 12L with grip is designed specifically for tractors and agricultural machinery where a reliable and durable connection solution is needed. This coupler enables the implementation of various connections effortlessly with an internal thread. The pressure relief valve and push-pull coupler offer flexible options for your needs. The quick and easy installation of the quick coupler saves time and increases work efficiency. Applications Tractors, agricultural machinery, hydraulic systems, industrial connections Industries Agriculture, construction industry, industry, logistics Benefits The universal female quick connector offers quick and simple installation, improving work efficiency and saving time. Chemical and corrosion resistance The connector is made of materials that are highly resistant to various chemicals and corrosion, ensuring a long service life even in demanding conditions. Sealing When installing, the connector is tightened with a cutting ring onto the 12mm hydraulic pipe. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Tractor quick connect male female pair at a good price is designed to provide a fast and reliable connection for the demanding needs of industry. This high-quality connector pair ensures efficient and safe use in various applications. The easy-to-use design allows for quick installation and removal, saving time and resources. Whether it is replacing an old connection or installing a new one, this product meets all requirements. Applications Hydraulic systems, pneumatic systems, agricultural machinery, industrial equipment Industries Agriculture, industry, transportation, construction Benefits This connector pair offers a reliable and long-lasting solution that reduces maintenance costs and improves system efficiency. Chemical and corrosion resistance The connector is made of materials that are highly resistant to chemicals and corrosion, ensuring the longevity of the product even in challenging environments. Sealing Press the edges together against the surface. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Thermoplastic hose R7 EN855 is a light and durable hose specially designed for high pressure hydraulic applications. This hose offers excellent chemical resistance and weather resistance, making it an excellent choice for demanding environments and applications where reliable performance is required. Thanks to its thermoplastic material, the hose is also very flexible and easy to handle, which improves its usability in a wide range of industrial applications. Applications Hydraulic systems, high pressure applications, mobile machinery, forklifts and other industrial machinery. Industries Civil engineering, agriculture, industrial automation, manufacturing industry. Benefits The hose offers excellent pressure resistance and chemical resistance, which reduces the need for maintenance and extends the service life. Risks Improper use or excessively high pressures can lead to hose damage, which can cause system failure. Adapters Compatible with all press-fit hydraulic fittings. Chemical resistance Excellent resistance to a wide range of chemicals and fluids, including petroleum and synthetic fluids. Operating temperatures -40°C to +100°C Operating pressure classes See the table. Certificates and classes DIN EN 855 R7 / SAE 100R7

We deliver ready-to-install hydraulic hose assemblies in series production for use by equipment and machine manufacturers, for example. Ask more from here or call.

The gasket kit for the Cejn 525 connector is designed to ensure a reliable and tight connection in demanding industrial applications. This high-quality kit includes all the necessary components to keep the connections leak-free and efficient. Its excellent compatibility with the Cejn 525 connector ensures a long-lasting and durable solution for various industrial needs. The gasket kit is easy to install, saving time and effort on the jobsite. Applications Hydraulic systems, compressed air lines, fluid transfer systems, industrial equipment Industries Automotive industry, manufacturing industry, energy sector, maritime industry Benefits The gasket set for the Cejn 525 connector offers excellent tightness and durability, which reduces the risk of leaks and extends the service life of the equipment. Chemical and corrosion resistance Seal materials have been carefully selected to be resistant to chemicals and corrosion, ensuring a long service life even in demanding environments.

Directional T-connector heavy series designed to split hydraulics in two different directions, making it an excellent choice for complex industrial applications. The internal thread in the center of the T-branch allows for precise orientation of the connector, and connecting to the pipe requires cutting rings and a nut. Reliability and ease of use make this connector an ideal choice for industrial professionals. Applications Hydraulic systems, industrial piping, maintenance work Industries Oil and gas industry, chemical industry, marine industry Benefits The directional tee offers versatility and precision in hydraulic system design. Its durable construction ensures long-lasting use in demanding conditions. Sealing The connector requires the correct size cutting rings and nut to ensure a tight connection. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The T-connector light series is designed for industrial needs, providing an efficient solution for dividing hydraulic flow in two directions. This connector with external thread is made of durable materials, which ensures longevity even in demanding conditions. Installation is easy with cutting rings and a nut, which ensures a safe and tight connection to the hydraulic pipeline. If necessary, our experts are ready to help you choose the right size and connector type. Applications Hydraulic systems, industrial piping, flow distribution Industries Engineering industry, oil and gas industry, marine and offshore industry Benefits The lightweight construction and durability make the T-connector an ideal choice for many industrial applications. Its easy installation saves time and resources. Chemical and corrosion resistance The T-connector is highly resistant to a wide range of chemicals, making it suitable for many industrial applications. Sealing The connector seals to the hydraulic pipe with a cutting ring. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The heavy duty swivel elbow is a premium quality hydraulic elbow fitting that provides a low and sturdy angled connection for a variety of hydraulic systems. This fitting requires a nut and bead on one end to successfully make the connection. The swivel is achieved with a heavy duty pipe clamp and matching female thread. Available in a range of sizes, it is easy to find the right fitting size. Applications Hydraulic systems, industrial applications, heavy equipment maintenance, engineering industry Industries Engineering industry, construction industry, transportation, agriculture Benefits The heavy duty swivel bracket series offers a reliable and durable connection that is easy to install and use in demanding conditions. High-quality materials ensure long service life and excellent performance. Risks Incorrect installation can lead to leakage or failure of the joint, which can cause significant costs and safety risks. Choosing the wrong size can reduce system performance and cause additional problems. Hoses Compatible connectors include pipe connectors according to DIN 2353 standard. Chemical resistance The connector is designed to withstand common hydraulic fluids, but always check compatibility with specific chemicals. Operating temperatures -40 to +180°C Operating pressure classes 400bar / 800bar Certificates and classes DIN 2353

The directional T-connector light series is an innovative solution for dividing hydraulics in two different directions. This connector is equipped with external and internal threads and an directional external thread nut, which allows for precise installation. The connector requires cutting rings and a nut to be used to securely attach it to the pipeline. It is designed specifically for industrial needs where a reliable and durable connector is required. Applications hydraulic systems, pipe division, industrial applications Industries engineering industry, process industry, energy industry Benefits The directional T-connector allows for easy and precise installation, reducing installation time and improving system efficiency. Chemical and corrosion resistance Resistant to most industrial chemicals, but it is recommended to check compatibility before use. Sealing The connector seals to the pipe with a cutting ring. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The directional elbow connector light series offers an effective solution for hydraulic systems where a low and sturdy elbow connection is required. This connector combines the light series pipe connection and internal thread, which allows the connector to be directional. The connection is easily made by adding a nut and bead to one end. Available in several different sizes, this product meets a variety of industrial needs. Applications Hydraulic systems, industrial piping, mechanical engineering Industries Industry, engineering, hydraulics Benefits The compact and durable design provides a reliable corner joint that is easy to align and install. Chemical and corrosion resistance The high-quality material ensures good chemical and corrosion resistance in most industrial applications. Sealing The connector seals from the JIC cone only to the thread. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The BSP/JIC Elbow is a versatile and durable connector designed specifically for the demands of hydraulic systems. Made from high-quality steel, this connector combines a BSP male thread with a flat seal and a UNF JIC male thread, allowing for easy change of angle direction. Its design makes the connector easy to twist into place, making it easy to use in a variety of industrial applications. Available in a variety of sizes, it is suitable for a wide range of needs. Applications Hydraulic systems, valve tables, industrial applications, machine maintenance Industries Industry, engineering, automotive, energy industry Benefits The adjustable elbow BSP/JIC allows for flexible and precise angle adjustment in hydraulic systems. Its durable construction and easy installation make it a reliable choice for various industries. Chemical and corrosion resistance The steel construction offers excellent resistance to chemicals and corrosion, extending the connector's service life even in demanding conditions. Sealing Flat seal with BSP male thread, UNF JIC male thread. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The directional JIC fitting with BSP thread is a robust and versatile solution for hydraulic systems where directional and sealing are key. This steel elbow fitting conveniently combines a UNF male thread and a JIC male thread, allowing for precise angle orientations while ensuring excellent sealing. Available in a variety of sizes, it is suitable for a wide range of industrial applications. Installation of this fitting is quick and easy, making it an ideal choice for busy work environments. Applications Hydraulic systems, angle design, pressure controls Industries Industry, shipping, construction, engineering Benefits The connector offers easy installation and versatility, reducing installation time and improving system efficiency. Chemical and corrosion resistance The steel construction ensures good resistance to chemicals and corrosion, which extends the connector's service life in challenging conditions. Sealing BSP thread with flat sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The directional bsp elbow is a steel and durable connector, specially designed for hydraulic systems. This internally threaded 90 degree elbow nipple is ideal for directional hydraulic lines and is part of the most commonly used connector series in hydraulics, also known as R-thread or pipe thread. Its easy installation and reliable performance make it an excellent choice for industrial professionals who value durability and efficiency. Applications Hydraulic systems, industrial equipment, engineering industry, construction industry Industries Automotive, construction, agriculture, marine industry Benefits BSP elbow with external threads enables efficient design and installation of hydraulic lines. It provides a durable solution that extends the service life of the system. Risks Selecting the wrong size or fitting can lead to leaks or system malfunctions. It is important to ensure the correct size before installation. Hoses Compatible connectors include R-threaded connectors, pipe connectors Chemical resistance Highly resistant to most common fluids used in hydraulics, such as oils and glycol-based fluids. Operating temperatures -50 - +200°C Operating pressure classes 250bar / 400bar

Orientable with a corner connector with an inch external thread. With this angle connector, you can leave, for example, a cylinder with a hard hydraulic pipe. A tightening nut in the directional external thread. This fitting requires shear rings and a nut to be attached to the pipe. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. Pipe connector DIN 2353

Directional 45° angle for hydraulic systems with BSP/JIC threads. Steel and sturdy corner for all hydraulic systems. This connector has a BSP male thread with flat sealing on one end and a UNF jic male thread on the other. This connector can be used to easily align corners in hydraulic systems, for example in valve tables. Due to its structure, the connector is easy to thread. This nipple is available in many different sizes. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone.

Kevyen Saraja pipe compression nipple internal and external threads. Hydraulic pipelines can be shortened with this tee connector. This fitting requires shear rings and a nut to be attached to the pipe. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. Pipe connector DIN 2353

Reduction connector for hydraulic pipe. With this connector, you can easily reduce or increase the size of the hydraulic pipe in hydraulic systems. This fitting requires shear rings and a nut to be attached to the pipe. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. Pipe connector DIN 2353

The straight extension coupling heavy duty series is specially designed for demanding industrial applications where a reliable and durable connection is required. This hydraulic extension coupling is ideal for extending hydraulic pipes and requires a nut and bead on both ends to ensure successful installation. The coupling features a heavy duty pipe grip with metric threads and is available in a variety of sizes. Choosing the right size is easy with our expert support. Applications Hydraulic systems, industrial piping, heavy machinery, construction machinery Industries Industry, construction, logistics, maritime industry Benefits The straight extension connector heavy duty series provides a secure and durable connection that can withstand heavy use and demanding conditions. Its versatility and compatibility with different sizes make it an ideal choice for many industrial needs. Risks An incorrectly selected size or poorly installed connector can lead to leaks and system malfunctions. It is important to ensure proper installation and component compatibility. Hoses Compatible with pipes and fittings according to DIN 2353 Chemical resistance The connector is highly resistant to a wide range of industrial chemicals, but it is recommended to check compatibility with specific substances. Operating temperatures -40 to +180°C Certificates and classes DIN 2353

The protective cap for Cejn 525 male coupling is designed to protect quick couplings in hydraulic systems from dirt and damage. This rubber protective cap ensures the functionality of the couplings and the cleanliness of the systems, which is especially important in demanding industrial conditions. The protective cap is easy to install and extends the service life of the coupling. It is an ideal solution for industrial professionals who value reliability and efficiency. Applications Hydraulic systems, agricultural machinery, construction machinery, industrial equipment Industries Industry, agriculture, construction, transportation Benefits The protective cap ensures the longevity and reliable operation of the quick connectors, which reduces maintenance costs and improves system efficiency. Chemical and corrosion resistance Durable rubber material protects connectors from chemical splashes and corrosion, improving system durability in demanding conditions. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The plastic protective spiral for hoses and cables is designed to provide effective protection against wear and mechanical damage. The easy-to-install and flexible spiral protects cables and hoses, extending their service life in demanding conditions. Its light weight and plastic construction make it an excellent choice for both indoor and outdoor use. The practical design allows the protective spiral to be used in a wide range of industrial applications. Applications Hydraulic systems, electrical cables, industrial automation Industries Construction industry, engineering industry, energy sector Benefits The protective spiral reduces the risk of wear on hoses and cables, which reduces maintenance costs and increases the reliability of the systems. Risks Improper installation or use can reduce the effectiveness of the protective spiral, which can lead to damage and downtime. Chemical resistance The protective spiral is resistant to most common chemicals, but it is recommended to check compatibility before use.

Hose protection is an innovative solution that provides effective protection for hoses in industrial environments. Made of durable and flexible material, this hose protection protects hoses from abrasion, chemicals and temperature fluctuations. Its easy installation and versatility make it ideal for various industries where hose durability and protection are paramount. Using a hose protection sleeve improves the lifespan of hoses and reduces maintenance costs, making it a cost-effective choice. Applications Hydraulic systems, chemical transfer lines, industrial production lines, construction sites Industries Industry, construction, mining, chemical industry Benefits A hose protection sleeve extends the life of hoses and improves safety by reducing the risk of hose breakage. It also protects the environment from potential leaks. Risks Without the use of a protective sleeve, hoses are exposed to wear and environmental damage, which can lead to premature failure. This can cause significant downtime and additional costs. Chemical resistance The protective sock is specifically designed to withstand a range of chemicals used in industry, making it a reliable choice for challenging environments.