Loose Flange 150lbs AISI 304 DN20 - DN300 is a high quality connector designed for the demanding needs of industry. Made from durable AISI 304 stainless steel, it guarantees excellent durability and longevity. This loose flange is particularly suitable for high pressure situations, providing a reliable and safe connection. The compact and efficient design makes it an ideal choice for various industrial applications. Applications Process piping, steam lines, chemical industry systems Industries Oil and gas industry, chemical industry, food industry, power plants Benefits The loose flange provides a strong and durable connection that is highly resistant to corrosion and high temperatures. Chemical and corrosion resistance AISI 304 steel offers excellent protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing PTFE seals, graphite seals Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

Loose Flange 300lbs AISI 304 DN20 - DN300 is a high quality connector designed for the demanding needs of industry. This loose flange is made of durable AISI 304 stainless steel, which ensures excellent durability and longevity. Particularly suitable for high pressure situations, providing a reliable and safe connection. The compact and efficient design makes it an ideal choice for various industrial applications. Applications Process piping, steam lines, chemical industry systems Industries Oil and gas industry, chemical industry, food industry, power plants Benefits The loose flange provides a strong and durable connection that is highly resistant to corrosion and high temperatures. Chemical and corrosion resistance AISI 304 steel offers excellent protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing PTFE seals, graphite seals Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

Loose flange PN16 AISI 304 DN20 - DN300 is a durable and versatile fitting made of high-quality AISI 304 stainless steel. This fitting is ideal for use in various industrial applications where a reliable and long-lasting connection is required. The product's wide DN size range from DN20 to DN300 allows it to be used in a wide variety of piping configurations. The PN16 pressure rating makes it suitable for high pressure requirements. Applications Pipelines, tank connections, heating and cooling systems, industrial process piping Industries Chemical industry, food industry, oil and gas industry, water supply and wastewater management Benefits The PN16 AISI 304 flange offers excellent durability and a reliable connection for demanding applications in various industrial sectors. Stainless steel ensures good corrosion resistance and longevity. Chemical and corrosion resistance Made of AISI 304 stainless steel, the loose flange is highly resistant to a variety of chemicals and corrosion, making it an ideal choice for challenging environments. Sealing Suitable for use with PTFE and rubber O-rings, ensuring a tight connection. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

The removable flange PN26 AISI 304 DN20 - DN300 is a high-quality connector made of durable and corrosion-resistant AISI 304 stainless steel. It is designed specifically for industrial needs that require a reliable and long-lasting connection solution. The applications are especially pipelines that require easy installation and removal. Suitable for different sizes, covering a wide range from DN20 to DN300. Applications Pipelines, valves, tanks, pumps Industries Chemical industry, food industry, pharmaceutical industry, energy Benefits The removable flange offers easy and quick installation and disassembly, saving time and costs during maintenance operations. It is compatible with a variety of pipelines, making it a versatile solution. Chemical and corrosion resistance Made of AISI 304 stainless steel, which offers excellent resistance to chemicals and corrosion, extending the product's lifespan in demanding environments. Sealing Suitable for use with various seals, such as PTFE and rubber seals. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

Loose flange PN10 AISI 304 DN20 - DN300 is designed to provide a reliable and durable connection for industrial needs. Made of high quality AISI 304 stainless steel, this loose flange is very durable in demanding conditions. Its compatibility with pipes from DN20 to DN300 makes it a versatile solution for various connection needs. PN10 pressure resistance ensures safe and stable use in a wide range of applications. Applications Pipeline connection, water treatment systems, heating and cooling systems, chemical and process industries. Industries Industry, construction, energy, chemical industry. Benefits High quality AISI 304 steel ensures longevity and corrosion resistance. Versatile DN20 - DN300 compatibility allows use in various systems. Chemical and corrosion resistance AISI 304 steel offers good protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing Suitable seals include PTFE and rubber seals, which ensure a tight connection. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

The PN6 AISI 304 DN20 - DN300 loose flange is a high-quality connector designed specifically for the demanding needs of industry. Made of high-quality AISI 304 stainless steel, this loose flange offers excellent durability and reliability. It is compatible with pipes from DN20 to DN300, making it a versatile solution for various connection needs. The PN6 pressure resistance ensures safe and stable use in a wide range of applications. Applications Pipeline connection, water treatment systems, heating and cooling systems, chemical and process industries. Industries Industry, construction, energy, chemical industry. Benefits High quality AISI 304 steel ensures longevity and corrosion resistance. Versatile DN20 - DN300 compatibility allows use in various systems. Chemical and corrosion resistance AISI 304 steel offers good protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing Suitable seals include PTFE and rubber seals, which ensure a tight connection. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

The 13 mm mold quick connector with tube set is a high-quality brass connector designed specifically for cooling molds on injection molding machines. This German-made connector offers efficient flow capacity and allows for easy one-handed connection, making it very practical in busy industrial environments. Its DN9 profile makes it a perfect fit for 13 mm tubes, and the durable material ensures a long service life. The connector is designed with both quality and reliability in mind. applications Mold cooling, injection molding machines, industrial cooling systems industries Plastics industry, manufacturing industry, engineering industry benefits The connector's ease of use and durable design reduce installation time and maintenance costs, while its excellent flow control improves cooling efficiency. chemical and corrosion resistance The brass construction offers good chemical resistance, and the stainless steel balls increase the connector's corrosion resistance. sealing FKM and PTFE seals

The 13 mm connector to 10/8 mm adapter tube 500 mm is designed to provide a reliable and efficient solution for industrial needs. This adapter tube combines a 13 mm connector and a 10/8 mm hose, allowing for a seamless and tight connection. Made of durable material, it is excellent for demanding conditions. The compact 500 mm length makes it versatile and easy to install. Applications Mechanical engineering, chemical industry, food industry, automation systems Industries Industry, energy, agriculture, construction Benefits The intermediate pipe ensures an efficient and leak-free connection, reducing maintenance needs and improving system reliability. Chemical and corrosion resistance The material is highly resistant to various chemicals and corrosion, which extends the product's lifespan and reduces the need for replacement. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

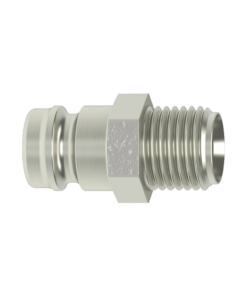

The quick-release male thread safety lock mold connector is designed to ensure safe and easy hose connections in the demanding environments of injection molding machines. This connector combines a durable construction with an innovative safety locking mechanism that prevents accidental loosening and minimizes the risk of leaks. The male thread connector is compatible with a wide range of industrial hoses, making it a versatile solution. High-quality material and precise manufacturing process ensure long service life and excellent performance. Applications Industrial liquid and gas transfer systems, hydraulic systems, chemical industry, injection molding industry. Industries Oil and gas industry, chemical industry, food industry, shipping Benefits The safety locking male thread of the quick-release formwork connector enables quick and safe installation, while reducing working time and maintenance costs. Chemical and corrosion resistance High-quality material and surface treatment ensure excellent resistance to both chemicals and corrosion, which extends the product's service life in demanding conditions. Sealing NBR seals, PTFE seals. The thread is sealed with tape, glue or directly to the hose. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The quick-release mold connector conversion 13mm body 9mm nipple allows you to easily change the size of the connector. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice for injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

The drip-free male aluminum connector is designed specifically for heavy-duty industrial applications where drip-free operation is an absolute requirement. This connector is made of durable, acid-resistant AISI 316 aluminum and includes viton seals that ensure excellent tightness when handling hazardous chemicals. The connector is attached to the hose via its internal thread, making it an easy-to-use and reliable option. Its construction ensures longevity and safety in demanding conditions. Applications Handling of hazardous chemicals, industrial processes, chemical industry, oil and gas industry Industries Chemical industry, oil and gas industry, heavy industry, process industry Benefits The drip-free design and tight connection ensure safety and efficiency when handling hazardous materials. The durable construction and high-quality materials ensure long-lasting use. Risks An incorrectly selected connector can cause leaks or other problems, highlighting the importance of choosing the correct size and type. Careful installation and regular maintenance are key to ensuring safety. Hoses Compatible hoses: chemical hose, oil hose, industrial hose Chemical resistance Highly resistant to most hazardous chemicals used in industry, especially thanks to the acid-resistant material. Operating temperatures -40 - +120°C Operating pressure classes 5bar / 25bar

The drip-free male connector AISI 316 is designed for demanding industrial applications where drip-free performance and durability are paramount. This acid-resistant connector is made of AISI 316 stainless steel and equipped with Viton seals, ensuring reliable performance when handling hazardous chemicals. The connector has an internal thread that allows for easy attachment to the hose. It is an ideal choice for heavy-duty industrial applications. Applications Transfer of hazardous chemicals, process industry applications, chemical storage, liquid transportation. Industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry. Benefits The drip-free male connector AISI 316 offers excellent corrosion resistance and reliable tightness. Its durable construction and acid-resistant material make it a long-lasting choice for demanding conditions. Risks An incorrectly selected connector can cause leaks and hazards, especially when handling chemicals. It is important to ensure the connector is compatible with the hoses and fluids being used. Hoses Compatible hoses include PTFE hoses, chemical hoses and high-pressure hoses. Chemical resistance AISI 316 stainless steel and Viton seals provide excellent resistance to a wide range of chemicals. Operating temperatures -40 to +150°C Operating pressure classes 10bar / 25bar

The drip-free female aluminum connector is designed specifically for heavy industry, where chemical handling requires absolute drip-free operation. This internally threaded connector is made of durable aluminum, and its body is made of acid-resistant AISI 316 material, which ensures excellent durability in demanding conditions. Viton seals ensure a tight and reliable connection to the hose. The connector is ideal for situations where safety and reliability are paramount. Applications Chemical handling, industrial processes, hazardous materials transportation Industries Chemical industry, oil and gas industry, petrochemical industry Benefits Its non-drip and durable design ensures safety and reliability in demanding conditions. Its easy installation and compatibility make it an excellent choice for industrial needs. Risks An incorrectly selected connector can lead to leaks and safety risks, especially when handling hazardous chemicals. It is important to ensure the correct size and compatibility of the connector. Hoses Compatible hoses: PTFE hoses, rubber-coated hoses, metal hoses Chemical resistance The connector is designed to withstand a variety of hazardous chemicals, making it an ideal choice for demanding applications. Operating temperatures -50 - +150°C Operating pressure classes 10bar / 25bar

The drip-free female connector AISI 316 is specially designed for heavy industry needs where high safety and drip-free operation are required. This acid-resistant connector is made of AISI 316 stainless steel, and its internal threads ensure a tight connection. Viton seals ensure excellent resistance to aggressive chemicals. The connector is easy to install and offers a reliable solution for demanding conditions. Applications Heavy industry, chemical industry, oil and gas industry, process industry Industries Chemical processing, petrochemical industry, energy production, marine industry Benefits The drip-free female connector AISI 316 provides a safe and tight connection that can withstand even the most demanding conditions. It reduces leaks and improves safety when handling hazardous materials. Risks Choosing the wrong size or type of connector can lead to leaks and safety risks. It is important to ensure compatibility with the hoses and connectors being used. Hoses Suitable for use with industrial hoses with threaded connections Chemical resistance AISI 316 steel and viton seals ensure excellent resistance to most chemicals. Operating temperatures -20 - +200°C Operating pressure classes 10bar / 25bar

The threaded reducing fitting is a versatile and durable solution for industrial applications where a reduced thread is required. Made from high-quality brass, this fitting is ideal for handling compressed air, water and fuels. Its design allows for easy installation and reliable use in demanding conditions. This makes it an ideal choice for industrial professionals looking for an efficient and long-lasting fitting. Applications Compressed air, water, fuels Industries Industry, marine industry, engineering industry Benefits The threaded reduction fitting offers a reliable seal and a durable construction that reduces maintenance requirements. It is designed for long service life. Risks If installed incorrectly, the connector can cause leaks or pressure loss. It is important to ensure that the connector is installed correctly and is suitable for the application being used. Hoses Compatible with various compressed air and fuel hoses Chemical resistance The brass construction offers good resistance to many chemicals, but it is recommended to check compatibility individually. Operating temperatures -20 - +120°C Operating pressure classes 10bar / 25bar Certificates and classes No certificates mentioned

The threaded coupling is a premium low-pressure coupling with inch threads, designed specifically for industrial applications. Its durable material makes it an excellent choice for handling compressed air, fuels and water. This versatile coupling provides a reliable connection that can withstand even the most demanding conditions. The threaded coupling is easy to install and guarantees long-lasting performance. Applications Compressed air, fuels, water Industries Industry, engineering workshops, energy industry Benefits The threaded coupling provides a reliable connection and durable performance in a variety of industrial applications. It is easy to install and requires little maintenance. Risks If installed incorrectly, a threaded sleeve can cause leaks and reduce the functionality of the system. It is important to ensure proper installation and regular inspection. Hoses Compatible with most standard threaded hoses Chemical resistance The threaded sleeve is highly resistant to most common industrial chemicals, making it a versatile solution. Operating temperatures -20 - +80°C Operating pressure classes 6bar / 18bar Certificates and classes No specific certifications or classes mentioned

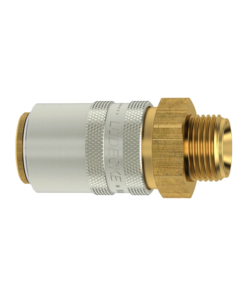

The 13mm mold quick connector body hose connector is designed for the demanding needs of the injection molding and plastics industries, providing a reliable and easy-to-use solution for managing hose connections. This connector allows for quick and safe connections, reducing downtime and increasing efficiency. Made from high-quality materials, it ensures excellent durability and longevity. The ideal choice when reliability and performance are required. Applications Injection molding machines, chemical pipelines, water distribution systems, compressed air lines Industries Chemical industry, food industry, engineering industry, water supply Benefits Quick installation and removal reduce downtime, high durability ensures a long service life. Chemical and corrosion resistance High-quality materials offer excellent resistance to chemicals and corrosion, ensuring a long service life even in demanding conditions.

The 13 mm Mold quick coupler without valve is a top quality product that offers excellent flows in the quick coupler. This connector with female external thread without internal valve has been widely used for mold cooling in injection molding machines. Applications Mold cooling, injection molding machines. Industries Industry, workshops, manufacturing. Benefits The connector's excellent flow capacity and high-quality construction guarantee longevity and reliability. Temperature duration +200°C. Risks If installed or maintained incorrectly, the connector can cause flow problems or leaks. Adapters Compatible with many industrial hoses. At high temperatures, we recommend using a Teflon hose instead of a rubber hose. Chemical resistance The connector is made of brass and equipped with FKM/PTFE seals, which are very resistant to chemicals. Certificates and classes Made in Germany, meets high quality standards.

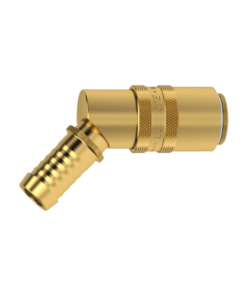

The 13 mm mold quick connector body angle is designed specifically for injection molding machines for demanding applications where a reliable and durable connection is required. This connector is an excellent choice for mold cooling on injection molding machines, as it allows for efficient flow and withstands high temperatures. The product, made in Germany, represents high quality and precise design. Its brass body, which is easy to use thanks to one-handed operation, guarantees a long service life. Applications Mold cooling, injection molding machines Industries Industry, plastic industry, engineering industry Benefits The connector is easy to use and durable, making it a reliable choice for industrial applications. Its design allows for long-term use at high temperatures. Chemical and corrosion resistance The connector is designed to withstand a wide range of chemicals and corrosion, making it an excellent choice for many industrial environments. Sealing FKM/PTFE seals

The 13 mm mold quick connector 45° hose connector is a reliable and dependable choice for industrial applications. This German-made female connector is particularly popular in injection molding machine molds where controlled flow and high temperature resistance are required. Applications Mold cooling, injection molding machines. Industries Industry, machine shops, plastic industry. Benefits The connector offers excellent flow and is easy to connect with one hand. The mesic connector withstands a temperature of +200°C. Risks Improper use or maintenance may result in connector damage or leakage. Hoses The connector is compatible with a variety of heat-resistant hoses. Chemical resistance The connector is made of brass and its seals are made of FKM / PTFE material, so it can withstand a wide range of chemicals. Certificates and classes The connector meets strict international standards. It is compatible with connectors from many different manufacturers.