The fire hose for water as a meter is an easy and reliable solution for industrial water transfer. This braided fire hose with a fabric surface is perfectly suited for various water transfer needs and is available in a convenient meter. Applications The fire hose is specially designed for water transfer in industrial applications. It serves in water and waste water transfers in the construction industry, in the irrigation systems of industrial halls and in many other areas where reliable water transfer is needed. Industries The construction industry, industrial halls, and all other sectors that require reliable water transfer. Benefits The braided fabric surface makes the fire hose durable and long-lasting. The inner material of the hose, EPDM, guarantees that it withstands very different weather conditions and maintains its flexibility within a wide temperature range (-20 °C/+60 °C). The pressure duration of the fire hose is 17 bar. Risks Improper use or maintenance of the hose can lead to damage, which emphasizes the importance of proper use and maintenance. Chemical resistance The braided fabric surface and the EPDM inner material of the hose ensure that the hose is resistant to a wide variety of chemicals. Make water transfer effortless and safe - request a quote for a fire hose for water and ensure the smoothness of water transfer in your industry.

AN hose black is specially designed for motorsport and tuning applications, offering excellent durability and performance. Its reinforced construction ensures longevity and reliability in demanding conditions. This steel braided hose is the ideal choice when you want to improve the performance and safety of your vehicle. Its versatility makes it an indispensable part for every car enthusiast. Applications Cooling systems, fuel systems, oil change systems, brake systems Industries Motor racing, automotive industry, tuning, industry Benefits AN steel braided hoses offer excellent pressure resistance and flexibility, making them perfect for heavy duty use and challenging conditions. Risks If installed incorrectly, steel braided hoses can lead to leaks or breakage, and their lifespan may be shortened if not properly maintained. Adapters AN hose is suitable for AN connectors intended for rubber hoses Chemical resistance AN steel braided hoses are highly resistant to a wide range of chemicals, but it is recommended to check chemical compatibility before use. Operating temperatures -40 - +120°C Operating pressure classes 10 bar / 30 bar

PVC plastic hose, which is suitable as a general hose for e.g. water. The nylon spiral keeps the hose open. The hose can be slightly warmed to facilitate the connection. The hose is light and flexible to use and excellent in Finland for outdoor use as well. Hose inner material: Transparent PVC Hose outer material: Transparent PVC Reinforcement: Nylon spiral Temperature: -10 °C/+60 °C Standard: EU 10/2011 A, B, C

TW connector hat aluminum is a high-quality and durable acid-resistant connector, designed specifically for chemical and fuel lines. It offers a very reliable connection, making it an excellent choice for industrial applications where reliability and durability are required. This connector is made of AISI 316 stainless steel, which ensures excellent corrosion resistance in demanding conditions. Especially suitable for tanker trucks handling chemicals. Applications Chemical line connections, fuel lines, tanker trucks Industries Chemical industry, fuel distribution, transportation sector Benefits TW connector cap Aluminum offers excellent corrosion resistance and reliable connection in demanding industrial applications. Its NBR seal ensures a tight connection that is resistant to chemicals and fuels. Chemical and corrosion resistance The connector, made of aluminum, is designed to withstand demanding chemical environments and effectively prevent corrosion. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The 13 mm mold quick connector with tube set is a high-quality brass connector designed specifically for cooling molds on injection molding machines. This German-made connector offers efficient flow capacity and allows for easy one-handed connection, making it very practical in busy industrial environments. Its DN9 profile makes it a perfect fit for 13 mm tubes, and the durable material ensures a long service life. The connector is designed with both quality and reliability in mind. applications Mold cooling, injection molding machines, industrial cooling systems industries Plastics industry, manufacturing industry, engineering industry benefits The connector's ease of use and durable design reduce installation time and maintenance costs, while its excellent flow control improves cooling efficiency. chemical and corrosion resistance The brass construction offers good chemical resistance, and the stainless steel balls increase the connector's corrosion resistance. sealing FKM and PTFE seals

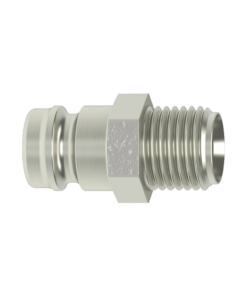

The acid-resistant pressure washer connector is designed to withstand demanding industrial conditions, providing a reliable and long-lasting solution to various connection challenges. This connector is made of high-quality AISI 316 stainless steel, which ensures excellent corrosion resistance even in chemically challenging environments. Applications Pressure washer hose connection. Industries Industry, mechanical engineering, energy sector, industrial and household needs in washing. Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing The connector seals easily to the mating part as long as the O-ring is intact. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Din straight pipe extension Aisi 316 is designed to provide a reliable and long-lasting solution for demanding industrial piping needs. This straight pipe extension is compatible with DIN 2353 fittings, allowing for easy installation and ensuring tight connections. Its heavy-duty construction ensures excellent performance and durability, even when using rigid pipes. Available in a range of sizes, the right option is easy to find. Applications Hydraulic systems, industrial piping, heavy machinery Industries Industry, mechanical engineering, energy sector Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing DIN 2353 dkos series acid-resistant connectors only seal to the body from their cone. This connector requires a cutting ring and a nut in addition to make the connection successful. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The 13 mm connector to 10/8 mm adapter tube 500 mm is designed to provide a reliable and efficient solution for industrial needs. This adapter tube combines a 13 mm connector and a 10/8 mm hose, allowing for a seamless and tight connection. Made of durable material, it is excellent for demanding conditions. The compact 500 mm length makes it versatile and easy to install. Applications Mechanical engineering, chemical industry, food industry, automation systems Industries Industry, energy, agriculture, construction Benefits The intermediate pipe ensures an efficient and leak-free connection, reducing maintenance needs and improving system reliability. Chemical and corrosion resistance The material is highly resistant to various chemicals and corrosion, which extends the product's lifespan and reduces the need for replacement. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The quick-release male thread safety lock mold connector is designed to ensure safe and easy hose connections in the demanding environments of injection molding machines. This connector combines a durable construction with an innovative safety locking mechanism that prevents accidental loosening and minimizes the risk of leaks. The male thread connector is compatible with a wide range of industrial hoses, making it a versatile solution. High-quality material and precise manufacturing process ensure long service life and excellent performance. Applications Industrial liquid and gas transfer systems, hydraulic systems, chemical industry, injection molding industry. Industries Oil and gas industry, chemical industry, food industry, shipping Benefits The safety locking male thread of the quick-release formwork connector enables quick and safe installation, while reducing working time and maintenance costs. Chemical and corrosion resistance High-quality material and surface treatment ensure excellent resistance to both chemicals and corrosion, which extends the product's service life in demanding conditions. Sealing NBR seals, PTFE seals. The thread is sealed with tape, glue or directly to the hose. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The quick-release mold connector conversion 13mm body 9mm nipple allows you to easily change the size of the connector. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice for injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

JIC T-fitting uk/sk/uk Aisi 316 is designed to provide a versatile and reliable solution for hydraulic systems. Made from high quality Aisi 316 stainless steel, this fitting can withstand harsh conditions and offers excellent corrosion resistance. The fitting has a UNF thread with a JIC seal, making it easy and quick to install. Available in a variety of sizes, this fitting is ideal for splitting hydraulic lines. Applications Hydraulic systems, hydraulic line distribution, industrial applications Industries Industry, shipping, engineering, construction Benefits Provides a durable and reliable solution for demanding applications. Easy to install and use in systems of various sizes. Chemical and corrosion resistance The Aisi 316 material offers excellent resistance to both chemicals and corrosion, making the connector a long-lasting choice. Sealing UNF thread with JIC seal Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Acid-resistant hydraulic tubing is designed for demanding industrial applications that require components with excellent durability. Made from high-quality material, this tubing is highly resistant to a wide range of chemical compounds and extreme environmental conditions. Its versatility and reliability make it the ideal choice for industrial professionals looking for a durable solution for their systems. Acid-resistant hydraulic tubing ensures reliable operation and longevity, saving time and money. Applications chemical industry, oil refineries, food industry, pharmaceutical industry Industries process industry, marine environment, energy industry, manufacturing industry Benefits Provides excellent resistance to corrosion, extending pipe life and reducing maintenance costs. Significantly reduces system downtime, improving efficiency and productivity. Risks Incorrect pipe size or connection type can cause leaks or damage to the system. Improper installation can reduce the durability of the pipe and shorten its service life. Adapters SAE J514, DIN 2353, ISO 8434-1 Chemical resistance Highly resistant to most industrial chemicals and acids, making it a reliable choice for a wide range of industrial applications.

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

The acid-resistant JIC hose connector male thread is designed to provide a reliable and durable solution for hydraulic installations. This high-quality connector allows for easy and safe connection of hydraulic hoses and is available in a variety of sizes. Its acid-resistant construction ensures longevity and performance even in demanding industrial environments. Applications Hydraulic hose assemblies in industry, machinery and mobile equipment. Industries Industry, hydraulics, machinery and equipment construction. Benefits The JIC male thread offers excellent corrosion resistance and reliability in assemblies. Chemical and corrosion resistance This jic male thread connector is made of acid-resistant steel and can withstand demanding chemical environments and offer excellent corrosion resistance. Sealing UNF male thread jic seal. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The acid-resistant double nipple bsp/mm is a high-quality fitting designed specifically for the demanding needs of industry. This fitting offers a reliable and durable solution for connecting different hose systems, making it an ideal choice for a wide range of applications. Its precise manufacturing process ensures excellent compatibility and longevity. The double nipple bsp/mm is easy to install and ensures a tight connection, reducing the risk of leaks. Applications Industrial piping, hydraulic systems, pneumatic systems, water treatment plants Industries Oil and gas industry, chemical industry, food industry, water supply Benefits The double nipple bsp/mm offers excellent tightness and durability, reducing the need for maintenance and improving system reliability. Risks An incorrectly installed connector can cause leaks, and incompatible materials can reduce the durability of the connection. Hoses Compatible connectors include BSP and metric hoses. Chemical resistance The double nipple bsp/mm is highly resistant to many industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50 - +200°C

The Acid Resistant Plug Heavy Duty Series is specially designed to withstand extreme conditions and chemicals. Made from high quality material, this plug offers excellent corrosion resistance and reliable sealing in demanding industrial environments. Its robust construction makes it an ideal choice for heavy duty applications where a long lasting and durable solution is required. Easy installation and versatility make it a popular choice among professionals. Applications Pipelines, tanks, valves, pumps, chemical plants Industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry Benefits The acid-resistant plug heavy series offers excellent protection against corrosion and ensures a tight seal. Its durable construction reduces maintenance and increases service life. Risks If installed incorrectly, the plug can cause leaks and increase the risk of corrosion. It is important to ensure correct installation and material compatibility with the chemicals used. Hoses Compatible with multiple industry standard connectors. Chemical resistance The plug is highly resistant to acids and alkalis, making it suitable for a wide range of chemical applications. Operating temperatures -50 - +200°C Operating pressure classes 300bar / 900bar Certificates and classes DIN 2353, AISI 316