Don't take the risk of using inferior brake hoses when you can rely on reliable and performance-enhancing brake hoses manufactured by the official distributor of HEL Performance, which are handcrafted in Porvoo. Most competitors use galvanized fittings that are prone to corrosion - our hoses and fittings are always made of stainless steel, which are durable. Our brake hose master has manufactured tens of thousands of brake hoses over the years, so you can always drive your car with confidence that your brake hoses are of high quality. This set contains a total of 4 hoses, so for only 210 euros you are guaranteed to get value for your money.

The T-branch of the compressed air pipeline is an essential component in industrial compressed air systems, enabling efficient air distribution in multiple directions. With this high-quality connector, you can easily connect multiple pipelines, improving system flexibility and efficiency. Its robust construction ensures long-term use even in challenging conditions, making it a reliable choice for various industries. Request a quote and upgrade your system efficiency to a new level. Applications Compressed air systems, pipeline branches, industrial production lines Industries Automotive industry, food industry, chemical industry, metal industry Benefits The T branch of the compressed air piping increases system flexibility and efficiency, reducing downtime and improving production efficiency. Chemical and corrosion resistance Made of durable material that provides excellent protection against chemicals and corrosion. Sealing The compressed air pipe is sealed to the connector with the O-ring and tightening ring in it using hand tools.

The 13 mm mold quick connector with tube set is a high-quality brass connector designed specifically for cooling molds on injection molding machines. This German-made connector offers efficient flow capacity and allows for easy one-handed connection, making it very practical in busy industrial environments. Its DN9 profile makes it a perfect fit for 13 mm tubes, and the durable material ensures a long service life. The connector is designed with both quality and reliability in mind. applications Mold cooling, injection molding machines, industrial cooling systems industries Plastics industry, manufacturing industry, engineering industry benefits The connector's ease of use and durable design reduce installation time and maintenance costs, while its excellent flow control improves cooling efficiency. chemical and corrosion resistance The brass construction offers good chemical resistance, and the stainless steel balls increase the connector's corrosion resistance. sealing FKM and PTFE seals

The 13 mm connector to 10/8 mm adapter tube 500 mm is designed to provide a reliable and efficient solution for industrial needs. This adapter tube combines a 13 mm connector and a 10/8 mm hose, allowing for a seamless and tight connection. Made of durable material, it is excellent for demanding conditions. The compact 500 mm length makes it versatile and easy to install. Applications Mechanical engineering, chemical industry, food industry, automation systems Industries Industry, energy, agriculture, construction Benefits The intermediate pipe ensures an efficient and leak-free connection, reducing maintenance needs and improving system reliability. Chemical and corrosion resistance The material is highly resistant to various chemicals and corrosion, which extends the product's lifespan and reduces the need for replacement. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

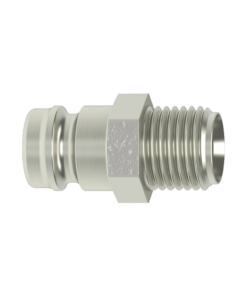

The quick-release male thread safety lock mold connector is designed to ensure safe and easy hose connections in the demanding environments of injection molding machines. This connector combines a durable construction with an innovative safety locking mechanism that prevents accidental loosening and minimizes the risk of leaks. The male thread connector is compatible with a wide range of industrial hoses, making it a versatile solution. High-quality material and precise manufacturing process ensure long service life and excellent performance. Applications Industrial liquid and gas transfer systems, hydraulic systems, chemical industry, injection molding industry. Industries Oil and gas industry, chemical industry, food industry, shipping Benefits The safety locking male thread of the quick-release formwork connector enables quick and safe installation, while reducing working time and maintenance costs. Chemical and corrosion resistance High-quality material and surface treatment ensure excellent resistance to both chemicals and corrosion, which extends the product's service life in demanding conditions. Sealing NBR seals, PTFE seals. The thread is sealed with tape, glue or directly to the hose. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The quick-release mold connector conversion 13mm body 9mm nipple allows you to easily change the size of the connector. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice for injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

Seamless hydraulic tubing is designed to withstand high pressure and provide reliable performance in demanding industrial environments. Its seamless construction is particularly appreciated for its durability and minimizing the risk of leakage, making it an ideal choice for critical applications. The low-friction inner surface ensures efficient fluid flow, which improves the energy efficiency of the system. This product is made of high-quality materials that ensure a long service life and low maintenance costs. Applications hydraulic systems, industrial and production plants, machine shops, heavy machinery Industries manufacturing industry, construction industry, maritime industry, transportation and logistics Benefits Seamless construction reduces the risk of leaks and optimizes system reliability. Durable material and construction extend service life and reduce maintenance. Risks Incorrect installation or overloading of hydraulic lines can lead to system failure. Regular inspection and correct installation are essential to ensure safe operation. Chemical resistance It is highly resistant to most industrial chemicals and hydraulic fluids, making it a versatile choice for a variety of applications.

The compressed air pipe connector is designed to make it easier to build and maintain a compressed air network for industrial needs. This rob connector allows you to connect through a hole drilled in an aluminum pipe, and if necessary, it can be started in two different directions. It makes it easy to implement a compressed air network in both industry and home workshops. Contact us to get a quote for the entire compressed air network. Applications Industrial compressed air networks, home workshops, aluminum piping Industries Manufacturing industry, workshops, garages Benefits The compressed air piping connector allows for quick and easy installation, saving time and costs. Its versatility makes it an ideal choice for a variety of industrial needs. Risks Professional installation is important to avoid potential leaks. If installed incorrectly, the connector can impair the operation of the compressed air network. Hoses Compatible connectors: aluminum pipe connectors, compressed air connectors Chemical resistance The compressed air piping connector is resistant to common industrial chemicals, but check compatibility with specialty chemicals. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar

The pneumatic pipe outlet connector is designed to facilitate the down-pipe installation of pneumatic pipes from the main line. This 25 mm connector is attached by drilling a hole in the pipe and tightening the connector around it. It provides a reliable and easy way to add new outlets to existing pipes. The solution is specifically designed for industrial needs where speed and efficiency are key. Applications Compressed air pipelines, industrial compressed air systems, downpipe additions, maintenance sites. Industries Industry, manufacturing, engineering, construction. Benefits The outlet connector allows for quick and easy modification of the compressed air piping without extensive modifications. It improves the flexibility and adaptability of the system. Risks If installed incorrectly, the connector can cause leaks, which can reduce the efficiency of the compressed air system. Careful installation is essential to prevent leaks. Hoses Compatible connectors: 25 mm compressed air piping. Chemical resistance The connector is resistant to most chemicals used in industry, but it is recommended to check compatibility with specific chemicals. Operating temperatures -20 - +80 Operating pressure classes 10 bar / 30 bar Certificates and classes No specific certificates mentioned.

The air line plug is an essential part of industrial compressed air systems, ensuring the safety and efficiency of the system. This aluminum plug is specially designed for aluminum piping, offering excellent compatibility and durability. Easy to install and remove, making it a practical and cost-effective solution. With the plug, you can ensure that your compressed air system operates flawlessly without leaks. Applications Compressed air systems, industrial piping, machine shops, service installations Industries Metal industry, automotive industry, food industry, chemical industry Benefits The aluminum plug offers excellent corrosion resistance and longevity. It is also lightweight, making it easy to handle and install. Risks If installed incorrectly, the plug can cause pressure leaks, which can lead to system inefficiency. It is important to ensure that the plug is tightly fitted and the correct size for the piping. Hoses Compatible with many industrial hoses designed for aluminum piping. Chemical resistance The aluminum plug is highly resistant to most chemicals used in industry, but it is recommended to check compatibility with particularly aggressive substances. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar Certificates and classes ISO 9001, CE approval

The compressed air network manifold is a durable and versatile solution for industrial compressed air systems. Made of aluminum, this 1/2" female threaded manifold provides a reliable connection point for the compressed air network. It includes a sturdy mounting rail for easy wall mounting. The manifold's design allows for versatile use in various industries. Applications compressed air networks, industrial plants, gas stations, production lines Industries automotive industry, food industry, engineering industry, chemical industry Benefits The compressed air network manifold offers easy and quick installation and a reliable connection solution. The aluminum construction ensures lightness and durability. Risks Incorrect installation or careless handling can lead to pressure losses or leakage at the connections. It is important to ensure that all connections are tight and correctly installed. Chemical resistance The aluminum manifold is highly resistant to common industrial chemicals, but is not suitable for acidic or alkaline substances. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar Certificates and classes No certifications or classes mentioned

The aluminum male thread connector for compressed air piping is designed to provide a durable and reliable solution for compressed air systems. This connector allows for easy and quick installation, making it an ideal choice for both industrial use and home workshops. Its durable construction ensures longevity and reliable operation even in demanding conditions. Request a quote and build an efficient compressed air network easily. Applications Industrial plants, garages, home workshops, compressed air networks Industries Mechanical engineering, automotive industry, service stations, households Benefits The connector offers easy installation and excellent durability, ensuring reliable operation of the compressed air network in the long term. Risks If installed incorrectly, the connector can cause leaks, reducing the efficiency of the system. Regular inspection and maintenance are recommended. Chemical resistance The aluminum structure is highly resistant to normal industrial chemicals, but is not suitable for acidic environments. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar

The aluminium T-connector for compressed air piping is an ideal solution for building compressed air networks in industry and home workshops. This internally threaded T-connector allows for easy expansion and connection of the network in different directions. Its durable construction ensures reliable operation even in demanding conditions. Request a quote and ensure a high-quality connector solution for your compressed air system. Applications Industrial compressed air networks, home workshops, machine shops, car repair shops Industries Manufacturing industry, automotive industry, engineering industry, maintenance and repair services Benefits The aluminum t-connector is lightweight and durable, allowing for easy installation and a long service life. It is suitable for a wide range of compressed air systems, making it a cost-effective choice. Risks An incorrectly selected connector can cause pressure losses or leaks, which reduces the efficiency of the system. It is important to ensure the compatibility of the connector with other components. Chemical resistance The aluminum construction offers good resistance to many industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar Certificates and classes No certificates mentioned

The compressed air pipe outlet connector with internal thread is a connector made of aluminum that offers a durable and reliable solution for building compressed air systems. This connector is designed to facilitate the installation and maintenance of compressed air networks, and is ideal for both industrial and home workshops. Its internal thread allows for versatile connectivity and ensures a tight connection that can withstand heavy use. Request a quote and make sure you get the best solution for your compressed air network needs. Applications Industrial compressed air networks, home workshops, compressed air tool connections, machine shops Industries Metal industry, automotive industry, carpentry industry, engineering industry Benefits The aluminum construction offers lightness and durability, which makes installation easier and reduces maintenance. The internal thread ensures a tight and reliable connection. Risks If installed incorrectly, the connector may cause air leaks, which will reduce the efficiency of the system. The compatibility of the connector must be verified before installation. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 18bar Certificates and classes No certifications or classes mentioned.

The aluminum pipe for the compressed air network is designed to provide a reliable and durable solution for industrial compressed air needs. This blue aluminum pipe is supplied in 4-meter rolls, making storage and transportation easy. The pipe's lightweight yet durable construction allows for easy installation and is ideal for both industrial use and home workshops. Aluminum pipe makes building a compressed air network fast and cost-effective. Applications Industrial plants, garages, workshops, home workshops Industries Manufacturing industry, automotive industry, engineering industry, aerospace industry Benefits Aluminum pipe offers excellent corrosion resistance and light weight, making it easier to install and reduce maintenance costs. It is also a long-lasting solution for compressed air networks. Risks When installing, ensure the correct pipe size and pressure resistance to avoid potential risks of leakage and breakage. Careless handling can cause damage to the pipe surface. Chemical resistance Aluminum pipe is highly resistant to most industrial chemicals, but it is recommended to check compatibility with specific chemicals. Operating temperatures -20 - +80 Operating pressure classes 16 bar Certificates and classes ISO 9001, CE marking

The aluminum elbow connector for compressed air piping is designed to connect pipes together easily and efficiently. Its lightweight yet durable construction makes it an ideal choice for both industrial professionals and home workshops. The elbow connector enables the construction of a compressed air network effortlessly and reliably. Request a quote and ensure that your compressed air network works flawlessly. Applications Compressed air networks, industrial plants, home workshops Industries Metal industry, automotive industry, wood processing industry, chemical industry Benefits The angle connector for compressed air piping ensures easy installation and a reliable connection, which minimizes downtime and streamlines production processes. Risks If the connector is not installed correctly, it can cause leaks and pressure losses, which can lead to production interruptions and additional costs. Hoses Compatible with many standardized compressed air pipes and hoses Chemical resistance The aluminum construction is highly resistant to most industrial chemicals, but is not suitable for use with highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar Certificates and classes No certifications or classes mentioned

The compressed air network bracket is designed to facilitate the installation of compressed air pipelines on walls and ceilings. This bracket allows pipes to be connected to each other simply and quickly, making network construction effortless. Perfectly suited for both industrial needs and home workshops, offering a versatile solution for building a compressed air network. Request a quote and ensure that you get the best possible solution for your needs. Applications Walls, ceilings, industrial plants, home workshops Industries Industry, construction, automotive, machine shops Benefits The compressed air network bracket enables quick and easy installation, saving time and resources. It is a durable and long-lasting solution that ensures reliable operation. Risks From an expert's perspective, risks can be caused by incorrectly selected fasteners or improper installation, which can lead to leaks or damage to the piping. Hoses Compatible connectors: standard pneumatic tube connectors Chemical resistance It is highly resistant to most common industrial chemicals, but it is recommended to check resistance when using special substances. Operating temperatures -20 - +80 Operating pressure classes 6bar / 18bar

The compressed air pipe extension connector is a durable and reliable solution made of aluminum for connecting compressed air system pipes. This connector allows for easy and quick construction of a network, which is ideal for both industrial environments and home workshops. With the extension connector, you ensure the seamless operation and efficient use of your compressed air system. Contact us and request a quote for a complete compressed air network. Applications Industrial plants, home workshops, compressed air systems Industries Manufacturing, automotive, construction, maintenance Benefits The compressed air piping extension connector offers ease of use and reliability, ensuring smooth and efficient operation of the compressed air system. Risks From an expert's perspective, it is important to ensure correct installation and compatibility of the fittings, as incorrect installation can lead to pressure losses or leaks. Hoses Compatible connectors: standard size compressed air hoses Chemical resistance The aluminum structure is highly resistant to most industrial chemicals, but it is recommended to check compatibility with specific chemicals. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar

Nlp spherical plain bearing housing is designed to protect and support spherical plain bearings, ensuring their longevity and efficiency. Made of durable cast iron or steel, it protects the bearings from dust and dirt, while promoting heat dissipation. This component is a key part of a wide range of industrial applications, such as electric motors and gearboxes. It ensures the smooth and uninterrupted operation of your equipment. Applications Electric motors, gearboxes, hydraulic cylinders, industrial machinery Industries Industry, mechanical engineering, automation, energy industry Benefits The NLP spherical plain bearing housing extends bearing life and improves performance. It protects bearings from contaminants and helps control temperature. Risks Without the right spherical plain bearing housing, bearings can be subject to excessive wear and overheating, which can lead to equipment malfunctions. Contamination can also significantly shorten the life of bearings.

The GE spherical plain bearing is a high-quality solution for industrial applications, designed to withstand radial loads and misalignment. Its unique design provides a sliding alignment surface, making it an excellent choice for heavy static and variable loads. The bearing requires lubrication and has a lubrication groove on its outer ring for this purpose. This spherical plain bearing provides reliability and performance for demanding industrial applications. Applications Industrial equipment, mechanical engineering, heavy loads, compensation of alignment errors Industries Engineering industry, heavy industry, manufacturing industry, mining industry Benefits GE spherical plain bearings are highly resistant to heavy loads and misalignment, which extends the life of equipment and reduces the need for maintenance. Risks Insufficient lubrication can lead to premature wear, and if installed incorrectly, the bearing may not function optimally. Chemical resistance The GE spherical plain bearing offers good resistance to a wide range of industrial chemicals, making it a reliable choice for demanding environments.