The 13 mm mold quick connector with tube set is a high-quality brass connector designed specifically for cooling molds on injection molding machines. This German-made connector offers efficient flow capacity and allows for easy one-handed connection, making it very practical in busy industrial environments. Its DN9 profile makes it a perfect fit for 13 mm tubes, and the durable material ensures a long service life. The connector is designed with both quality and reliability in mind. applications Mold cooling, injection molding machines, industrial cooling systems industries Plastics industry, manufacturing industry, engineering industry benefits The connector's ease of use and durable design reduce installation time and maintenance costs, while its excellent flow control improves cooling efficiency. chemical and corrosion resistance The brass construction offers good chemical resistance, and the stainless steel balls increase the connector's corrosion resistance. sealing FKM and PTFE seals

The 13 mm connector to 10/8 mm adapter tube 500 mm is designed to provide a reliable and efficient solution for industrial needs. This adapter tube combines a 13 mm connector and a 10/8 mm hose, allowing for a seamless and tight connection. Made of durable material, it is excellent for demanding conditions. The compact 500 mm length makes it versatile and easy to install. Applications Mechanical engineering, chemical industry, food industry, automation systems Industries Industry, energy, agriculture, construction Benefits The intermediate pipe ensures an efficient and leak-free connection, reducing maintenance needs and improving system reliability. Chemical and corrosion resistance The material is highly resistant to various chemicals and corrosion, which extends the product's lifespan and reduces the need for replacement. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

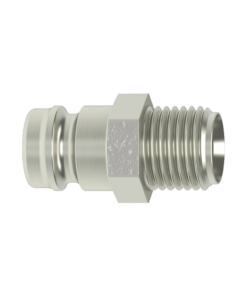

The quick-release male thread safety lock mold connector is designed to ensure safe and easy hose connections in the demanding environments of injection molding machines. This connector combines a durable construction with an innovative safety locking mechanism that prevents accidental loosening and minimizes the risk of leaks. The male thread connector is compatible with a wide range of industrial hoses, making it a versatile solution. High-quality material and precise manufacturing process ensure long service life and excellent performance. Applications Industrial liquid and gas transfer systems, hydraulic systems, chemical industry, injection molding industry. Industries Oil and gas industry, chemical industry, food industry, shipping Benefits The safety locking male thread of the quick-release formwork connector enables quick and safe installation, while reducing working time and maintenance costs. Chemical and corrosion resistance High-quality material and surface treatment ensure excellent resistance to both chemicals and corrosion, which extends the product's service life in demanding conditions. Sealing NBR seals, PTFE seals. The thread is sealed with tape, glue or directly to the hose. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The quick-release mold connector conversion 13mm body 9mm nipple allows you to easily change the size of the connector. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice for injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

The low pressure reducing nipple is designed for industrial requirements, providing a reliable connection in low pressure systems. Its durable construction ensures longevity and reduces the need for maintenance. Made from high-quality materials, the reducing nipple is suitable for a wide range of applications. Easy installation and compatibility with many hose types make it a versatile choice. Applications Compressed air systems, water systems, industrial process piping Industries Chemical industry, food industry, engineering industry Benefits The low pressure reducing nipple ensures a tight and secure connection, reducing the risk of leaks and improving system efficiency. Chemical and corrosion resistance Highly resistant to most common industrial chemicals and provides excellent protection against corrosion. Sealing The thread is sealed with Teflon tape or thread glue. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Are you looking for an efficient and versatile twist lock? Weiconlock AN 302-43 is a high-viscosity and medium-strength thread lock that is perfectly suited for general use. The fact that it can be removed with normal tools makes it effortless and easy to use. Weiconlock AN 302-43 spiral lock crystal is blue in color and its viscosity according to the Brookfield method is 2,000–7,000 mt at +25 °C. It is suitable for a maximum M36 thread and its partial gap filling capacity is 0.25 mm. This spiral lock can withstand temperatures from -60 °C to +150 °C. Interestingly, the Weiconlock AN 302-43 twist lock is approved for use in gases and hot water (KTW) and meets the DVGW standard. It is available in 50 ml and 200 ml packs.

Are you looking for an efficient and versatile twist lock? Weiconlock AN 302-43 is a high-viscosity and medium-strength thread lock that is perfectly suited for general use. The fact that it can be removed with normal tools makes it effortless and easy to use. Weiconlock AN 302-43 spiral lock crystal is blue in color and its viscosity according to the Brookfield method is 2,000–7,000 mt at +25 °C. It is suitable for a maximum M36 thread and its partial gap filling capacity is 0.25 mm. This spiral lock can withstand temperatures from -60 °C to +150 °C. Interestingly, the Weiconlock AN 302-43 twist lock is approved for use in gases and hot water (KTW) and meets the DVGW standard. It is available in 50 ml and 200 ml packs.

Are you looking for an efficient and versatile twist lock? Weiconlock AN 302-43 is a high-viscosity and medium-strength thread lock that is perfectly suited for general use. The fact that it can be removed with normal tools makes it effortless and easy to use. Weiconlock AN 302-43 spiral lock crystal is blue in color and its viscosity according to the Brookfield method is 2,000–7,000 mt at +25 °C. It is suitable for a maximum M36 thread and its partial gap filling capacity is 0.25 mm. This spiral lock can withstand temperatures from -60 °C to +150 °C. Interestingly, the Weiconlock AN 302-43 twist lock is approved for use in gases and hot water (KTW) and meets the DVGW standard. It is available in 50 ml and 200 ml packs.

The curing time can be significantly shortened by pretreatment with WEICONLOCK Activator F. The actuator is recommended for all passive surfaces and is essential in low ambient temperatures (below +10°C / +50°F) and in large gaps. On non-metallic surfaces, WEICONLOCK can only harden completely when an activator is used. Delivery time 3-5 days

Bearing crystal, fast hardening, medium viscosity, high strength, difficult joint disassembly. Food approved. Delivery time: 3-5 days

Bearing crystal, fast hardening, medium viscosity, high strength, difficult joint disassembly. Food approved. Delivery time: 3-5 days

Bearing crystal, fast hardening, medium viscosity, high strength, difficult joint disassembly. Food approved. Delivery time: 3-5 days

Bearing crystal, fast hardening, medium viscosity, high strength, difficult joint disassembly. Food approved. Delivery time: 3-5 days

Bearing crystal, fast hardening, medium viscosity, high strength, difficult joint disassembly. Food approved. Delivery time: 3-5 days

Bearing crystal, fast hardening, medium viscosity, high strength, difficult joint disassembly. Food approved. Delivery time: 3-5 days

Cylindrical mounting assemblies for passive materials. Food approval Delivery time: 3-5 days

Cylindrical mounting assemblies for passive materials. Food approval Delivery time: 3-5 days

Cylindrical mounting assemblies for passive materials. Food approval Delivery time: 3-5 days

Bearing crystal, low viscosity, high strength, difficult joint disassembly. Delivery time: 3-5 days