Don't take the risk of using inferior brake hoses when you can rely on reliable and performance-enhancing brake hoses manufactured by the official distributor of HEL Performance, which are handcrafted in Porvoo. Most competitors use galvanized fittings that are susceptible to corrosion - our hoses and fittings are always made of stainless steel, which are durable. Our brake hose master has manufactured tens of thousands of brake hoses over the years, so you can always drive your car with confidence that your brake hoses are of high quality. This set contains a total of 4 hoses, so for only 113.4 euros you are guaranteed to get value for your money.

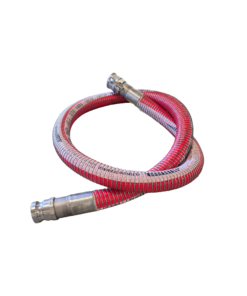

Composite hose 2" female saflok is designed to withstand demanding industrial conditions where reliability and chemical resistance are key. Its durable and flexible construction ensures easy connection and quick installation, making it an ideal choice for professionals. The hose is equipped with 2" camlock fittings, which allow for smooth connection to various systems. The Teflon inner surface ensures excellent chemical resistance, expanding the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Teflon coating inside the hose ensures excellent chemical resistance. Acid-resistant safety locking Saflok cam lever connector ensures the safety of the pressurized hose. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female saflok is designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible construction makes handling and installation easy. Acid-resistant camlocks ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose has a Teflon membrane on the inside and acid-resistant connectors. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 3" male threads are designed for the demanding needs of industrial chemical transfer, offering excellent durability and versatility in various conditions. This hose is made of high-quality materials, ensuring long service life and reliable performance. The 3 inch composite hose with acid-resistant male threads is easy to connect and install, making it an ideal choice for industrial professionals. The Teflon inner surface of the hose provides a wide range of chemical resistance. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The composite construction offers lightness and flexibility, making the hose easy to handle and install. The high-quality materials ensure excellent durability in demanding industrial environments. Risks Although the hose is designed to withstand a variety of chemicals, improper or excessive pressure can cause damage. It is important to ensure that the hose is installed correctly and used within the recommended operating conditions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose is highly resistant to a wide range of chemicals, making it ideal for demanding industrial applications. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes Hoses are manufactured and tested according to EN 13765 - IMO IBC code.

The 13 mm mold quick connector with tube set is a high-quality brass connector designed specifically for cooling molds on injection molding machines. This German-made connector offers efficient flow capacity and allows for easy one-handed connection, making it very practical in busy industrial environments. Its DN9 profile makes it a perfect fit for 13 mm tubes, and the durable material ensures a long service life. The connector is designed with both quality and reliability in mind. applications Mold cooling, injection molding machines, industrial cooling systems industries Plastics industry, manufacturing industry, engineering industry benefits The connector's ease of use and durable design reduce installation time and maintenance costs, while its excellent flow control improves cooling efficiency. chemical and corrosion resistance The brass construction offers good chemical resistance, and the stainless steel balls increase the connector's corrosion resistance. sealing FKM and PTFE seals

The compressed air T-connector with center male thread is designed for efficient compressed air distribution and secure connection management in industrial environments. This connector allows for three-way compressed air distribution, making it an ideal choice for complex systems. Made of durable material, it offers reliability and longevity for daily use. Compatibility with various compressed air systems makes it a versatile solution. Applications Compressed air systems, industrial distribution systems, machine shops Industries Manufacturing industry, automotive industry, construction industry Benefits The compressed air T-connector offers a reliable solution for managing complex compressed air systems. It enables efficient air distribution, reducing downtime and improving system efficiency. Chemical and corrosion resistance Made from high-quality materials, this connector is resistant to multiple chemicals and is protected against corrosion, ensuring longevity. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The pneumatic directional elbow is designed to provide a reliable and durable solution for industrial compressed air systems. This connector ensures a seamless and secure connection in various compressed air applications, reducing the risk of leaks and improving system efficiency. Made of high-quality materials, it withstands harsh operating conditions and offers a long service life. As an easy-to-install connector, it is compatible with a wide range of standard hoses. Applications Industrial compressed air systems, machine shops, production lines, automation systems Industries Manufacturing industry, automotive industry, food industry, chemical industry Benefits The compressed air extension connector ensures an efficient and leak-free connection, reducing maintenance costs and optimizing system performance. Chemical and corrosion resistance High-quality materials ensure excellent resistance to chemicals and corrosion, extending the connector's service life in demanding environments. Sealing Remove the nut from the fitting and thread it onto the hose. Push the hose into the bottom of the fitting and tighten the nut. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The compressed air outlet connector is designed to provide a reliable and durable solution for industrial compressed air systems. This connector ensures a seamless and secure connection in various compressed air applications, reducing the risk of leaks and improving system efficiency. Made of high-quality materials, it withstands demanding operating conditions and offers a long service life. As an easy-to-install connector, it is compatible with a variety of standard hoses. Applications Industrial compressed air systems, machine shops, production lines, automation systems Industries Manufacturing industry, automotive industry, food industry, chemical industry Benefits The compressed air extension connector ensures an efficient and leak-free connection, reducing maintenance costs and optimizing system performance. Chemical and corrosion resistance High-quality materials ensure excellent resistance to chemicals and corrosion, extending the connector's service life in demanding environments. Sealing Remove the nut from the fitting and thread it onto the hose. Push the hose into the bottom of the fitting and tighten the nut. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The compressed air elbow outlet connector is designed to provide a reliable and durable solution for industrial compressed air systems. This connector ensures a seamless and secure connection in various compressed air applications, reducing the risk of leaks and improving system efficiency. Made of high-quality materials, it withstands harsh operating conditions and offers a long service life. As an easy-to-install connector, it is compatible with a variety of standard hoses. Applications Industrial compressed air systems, machine shops, production lines, automation systems Industries Manufacturing industry, automotive industry, food industry, chemical industry Benefits The compressed air extension connector ensures an efficient and leak-free connection, reducing maintenance costs and optimizing system performance. Chemical and corrosion resistance High-quality materials ensure excellent resistance to chemicals and corrosion, extending the connector's service life in demanding environments. Sealing Remove the nut from the fitting and thread it onto the hose. Push the hose into the bottom of the fitting and tighten the nut. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The compressed air elbow extension is designed to provide a reliable and durable solution for industrial compressed air systems. This connector allows for a seamless and secure connection in various compressed air applications, reducing the risk of leaks and improving system efficiency. Made of high-quality materials, it withstands demanding operating conditions and offers a long service life. The connector is easy to install and compatible with hoses of various standards. Applications Industrial compressed air systems, machine shops, production lines, automation systems Industries Manufacturing industry, automotive industry, food industry, chemical industry Benefits The compressed air extension connector ensures an efficient and leak-free connection, reducing maintenance costs and optimizing system performance. Chemical and corrosion resistance High-quality materials ensure excellent resistance to chemicals and corrosion, extending the connector's service life in demanding environments. Sealing Remove the nut from the fitting and thread it onto the hose. Push the hose into the bottom of the fitting and tighten the nut. Finding the right size The determining factor for compressed air fittings is the outer diameter of the hose. So choose the fitting according to the outer diameter of the hose.

The 13 mm connector to 10/8 mm adapter tube 500 mm is designed to provide a reliable and efficient solution for industrial needs. This adapter tube combines a 13 mm connector and a 10/8 mm hose, allowing for a seamless and tight connection. Made of durable material, it is excellent for demanding conditions. The compact 500 mm length makes it versatile and easy to install. Applications Mechanical engineering, chemical industry, food industry, automation systems Industries Industry, energy, agriculture, construction Benefits The intermediate pipe ensures an efficient and leak-free connection, reducing maintenance needs and improving system reliability. Chemical and corrosion resistance The material is highly resistant to various chemicals and corrosion, which extends the product's lifespan and reduces the need for replacement. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

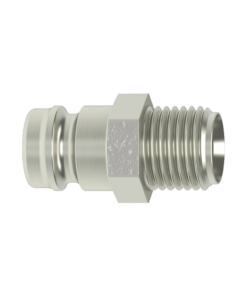

The quick-release male thread safety lock mold connector is designed to ensure safe and easy hose connections in the demanding environments of injection molding machines. This connector combines a durable construction with an innovative safety locking mechanism that prevents accidental loosening and minimizes the risk of leaks. The male thread connector is compatible with a wide range of industrial hoses, making it a versatile solution. High-quality material and precise manufacturing process ensure long service life and excellent performance. Applications Industrial liquid and gas transfer systems, hydraulic systems, chemical industry, injection molding industry. Industries Oil and gas industry, chemical industry, food industry, shipping Benefits The safety locking male thread of the quick-release formwork connector enables quick and safe installation, while reducing working time and maintenance costs. Chemical and corrosion resistance High-quality material and surface treatment ensure excellent resistance to both chemicals and corrosion, which extends the product's service life in demanding conditions. Sealing NBR seals, PTFE seals. The thread is sealed with tape, glue or directly to the hose. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The quick-release mold connector conversion 13mm body 9mm nipple allows you to easily change the size of the connector. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice for injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

Compressed air hose for push-in connector is designed to meet the demanding needs of industry by offering excellent durability and flexibility. Made from high-quality nylon tube PA12 material, this hose is suitable for a wide range of industrial applications where a reliable and long-lasting solution is required. Its wide operating temperature range and chemical resistance make it an ideal choice for a variety of environments. Available in various sizes, this hose is perfect for both building new systems and maintaining existing ones. Applications Compressed air systems, hydraulic systems, chemical pipelines, food industry. Industries Automotive industry, pharmaceutical industry, chemical industry, food industry. Benefits PA12 nylon pipe offers excellent durability and flexibility, reducing the risk of breakage and extending service life. Its light weight makes it easy to install and handle. Risks At high temperatures, the mechanical strength of nylon tubing may be reduced. At low temperatures, the flexibility of the tubing may be reduced, which may affect its use in certain applications. Chemical resistance PA12 nylon is highly resistant to most chemicals, such as oils and solvents, making it suitable for many industrial applications. Operating temperatures -40 - +100°C Operating pressure classes 10bar / 20bar Certificates and classes

The male thread push-in fitting is designed to provide a reliable and durable solution for industrial applications. This high-quality fitting is compatible with a wide range of compressed air hoses, making it an excellent choice for a variety of applications. Its durable construction ensures longevity and reduces maintenance. Easy installation and versatility make it an ideal part of compressed air systems. Applications Compressed air systems, procurement and replacement of hoses, transfer of compressed air. Industries Industry, construction industry, automotive industry, machine shops, production industry. Benefits Plug connector angle for compressed air, external thread provides reliability and longevity. It is easy to install and compatible with many different hoses. Chemical and corrosion resistance Made of high-quality material that is highly resistant to chemicals and corrosion, ensuring the longevity of the product. Sealing The hose seals when pushed into the bottom of the plug connector. The hose can be removed from the plug connector by pressing the ring in and pulling the hose out. The thread seals against its ring. Finding the right size In push-in fittings, the outer diameter of the hose determines the size of the fitting. So choose the push-in fitting according to the outer diameter of the hose.

Chewing hose 0.7mm wall is a durable and transparent product, which is equipped with a metal spiral, which gives the hose additional strength and durability. Its wall thickness is 0.7 mm, and it offers good abrasion resistance and enables easy monitoring of liquid or air flow. Applications Chewing hose is designed for many different uses, including ventilation of industry, buildings and other premises and for transporting granular materials. It is also suitable as a hose for brush machines used in property maintenance, Industries Industry, construction, ventilation, cleaning. Benefits The chew hose offers excellent protection against fires and is highly resistant to oil and gasoline, making it useful for a wide variety of applications. Risks As a result of misuse or neglect of maintenance, the hose can become damaged or leak, emphasizing the importance of proper use and maintenance. Adapters The chewing hose is compatible with a wide variety of connectors, allowing it to be integrated into a wide variety of transfer systems. Chemical resistance The chew tube is designed to resist hydrolysis and microbes, making it a long-lasting choice. Operating temperatures The chewing hose has an operating temperature of -40 °C/+100 °C, so it is suitable for many different applications. Operating pressure classes The operating pressure class of the chewing hose is defined based on the use and explosion pressure class. Certificates and classes The chewing hose meets DIN 4102 B 1, ISO 8031 <109Ohm ja TRGS 727 <2,5108Ohm*m, ATEX 2014/34/EU ja DIN 26057 -standardit. Tutustu valikoimaamme ja pyydä tarjous jo tänään!

Here is a Chewing Hose with a 1.0mm wall, designed especially for industrial needs. It is the perfect solution for suction and blowing applications of consumables, offering a durable and versatile alternative. Applications The chewing hose is ideal for transporting lighter goods such as sawdust, dust and flour, as well as coarser material such as pellets, wood chips and grain. Industries Industry, construction, agriculture, wood processing. Property maintenance brush machines. Benefits This hose is very durable and long-lasting, maintaining its flexibility in varying temperatures (-40...+90 °C). Risks Improper use or maintenance can lead to damage to the hose and shorten its service life. Adapters The chew tube is compatible with several different connectors. Hoses Compatible with many different hoses. Chemical resistance The chewing hose is made to withstand various chemicals, offering reliability and longevity. Operating temperatures -40 - +90 Operating pressure classes 5 bar / 15 bar Certificates and classes DNV-GL, Bureau Veritas (BV), American Bureau of Shipping (ABS), EN 1474-II, EN 12434, EN 1474-III. We offer comprehensive advice on the selection of hoses, ensuring that you get a solution that suits your needs. Request a quote for Chewing Hose with 1.0mm wall today! Resistance