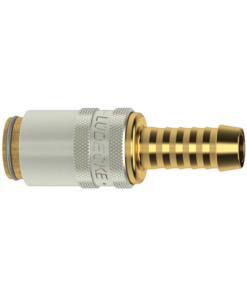

The 9 mm Quick Release Male Connector is a high-quality connector designed specifically for injection molding machines. Its simple and efficient design allows for quick and easy connection and disconnection, making it an excellent choice for industrial professionals. The connector is made of durable materials such as brass and stainless steel, ensuring its longevity and reliability in demanding conditions. This connector offers a cost-effective solution for a variety of industrial needs. Applications Injection molding machines, industrial equipment and equipment that require reliable joints. Industries Industrial machine shops, manufacturing plants, equipment manufacturers. Benefits The 9 mm mold quick coupler is durable and easy to use, making it an ideal choice for cost-effective production. Chemical and corrosion resistance Brass and stainless steel ensure excellent chemical and corrosion resistance, which increases the service life of the connector. Temperature resistance + 200c°, Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The acid-resistant pressure washer connector is designed to withstand demanding industrial conditions, providing a reliable and long-lasting solution to various connection challenges. This connector is made of high-quality AISI 316 stainless steel, which ensures excellent corrosion resistance even in chemically challenging environments. Applications Pressure washer hose connection. Industries Industry, mechanical engineering, energy sector, industrial and household needs in washing. Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing The connector seals easily to the mating part as long as the O-ring is intact. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The 9mm male thread elbow is designed to ensure seamless connectivity and durability in demanding industrial applications. Its carefully designed angle allows for optimal flow dynamics and reduces turbulence, improving system efficiency. Its compact design and high-quality materials make it the ideal choice when a reliable and long-lasting connector is needed. Easy installation and compatibility with a wide range of hoses make it a versatile solution. Applications Process industry, hydraulic systems, compressed air systems, cooling systems Industries Chemical industry, food industry, marine industry, mechanical engineering Benefits The highly durable and rust-resistant construction ensures a long service life. Easy installation saves time and reduces costs. Chemical and corrosion resistance The corner of the mold plug is designed to withstand multiple chemicals and prevent corrosion, extending the product's lifespan even in challenging environments. Sealing O-ring seals, PTFE seals. The thread is sealed from its thread with tape or glue. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

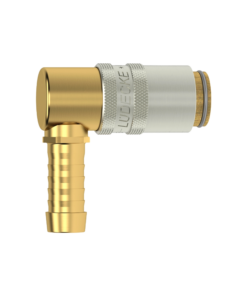

The 9mm elbow without valve is designed to provide a reliable and durable connection for industrial applications. This connector is especially suitable for situations where optimal elbow handling without a valve connection is required. Its compact design makes it easy to install in tight spaces, and its robust construction ensures longevity in demanding environments. An excellent choice when you are looking for an efficient and easy-to-use connector for industrial needs. Applications Hydraulic systems, industrial piping, chemical industry Industries Mechanical engineering, process industry, chemical industry Benefits The moulded valve body offers easy installation and removal without separate valves, saving time and costs. In addition, the angled design allows for flexible connection even in tight spaces. Chemical and corrosion resistance Made from durable materials, this connector offers good protection against a wide range of chemicals and corrosion, extending its service life in demanding conditions. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

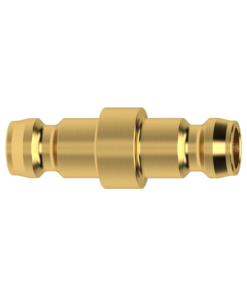

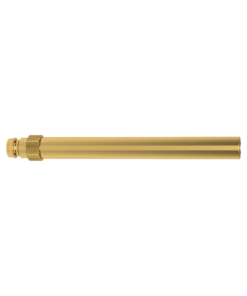

The quick-connector extension nipple 9mm allows you to easily extend hoses on injection molding machines, for example. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice on injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

The quick-release mold connector conversion 13mm body 9mm nipple allows you to easily change the size of the connector. The conversion connector is a very reliable and reliable product, designed specifically for mold cooling. This German-made female connector offers excellent flow, making it a very popular choice for injection molding machines. Applications Mold cooling, injection molding machines. The temperature resistance of the connector is +200°C. Industries Industry, especially the plastics industry. Benefits The connector's excellent flow and German quality guarantee reliability and longevity. Risks Improper use or maintenance may result in connector damage or leakage. Adapters Compatible with HASCO Z80/13, HASCO Z801/13, RECTUS 11, DYROS hoses. Chemical resistance The materials of the connector, such as brass and stainless steel, guarantee resistance against various chemicals.

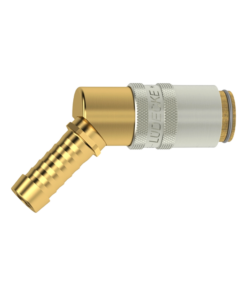

The mold quick connector angle without valve 9mm is a high-quality connector used in mold cooling. The valveless design allows for maximum flow in mold cooling. The hose connector is a high-quality, German-made quick connector that is designed to withstand the demanding conditions of injection molding machines. It is easy to connect and disconnect with one hand, making it very user-friendly. Applications Industrial machines and equipment that require a reliable and heat-resistant connector. Industries Injection molding, machine shops, manufacturing, maintenance and repair. Benefits The mold quick connector is reliable and durable, which reduces the need for maintenance and replacement. Risks Improper use or maintenance can lead to connector damage, emphasizing the importance of proper use and maintenance. Adapters Compatible with many different hose types. The connector has a temperature resistance of +200°c Chemical resistance Made to withstand industrial chemicals, providing reliability and longevity. Certificates and classes Made in Germany, from high quality materials.

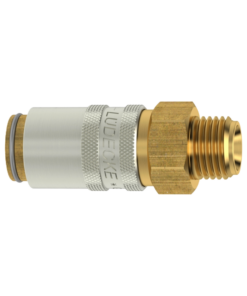

The 9mm male thread, valveless, mold quick connector is a high-quality connector designed specifically for injection molding machines. Its efficient design allows for quick and easy connection and disconnection, making it an excellent choice for industrial professionals. The connector is made of durable materials such as brass and stainless steel, ensuring its longevity and reliability in demanding conditions. This connector offers a cost-effective solution for a variety of industrial needs. Applications Injection molding machines, industrial equipment and equipment that require reliable joints. Industries Industrial machine shops, manufacturing plants, equipment manufacturers. Benefits The 9 mm mold quick coupler is durable and easy to use, making it an ideal choice for cost-effective production. Chemical and corrosion resistance Brass and stainless steel ensure excellent chemical and corrosion resistance, which increases the service life of the connector. Temperature resistance + 200c°, Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The 9mm valveless mold quick connector allows for maximum flow when cooling molds. The hose connector is a high-quality, German-made quick connector designed to withstand the demanding conditions of injection molding machines. It is easy to connect and disconnect with one hand, making it very user-friendly. Applications Industrial machines and equipment that require a reliable and heat-resistant connector. Industries Injection molding, machine shops, manufacturing, maintenance and repair. Benefits The mold quick connector is reliable and durable, which reduces the need for maintenance and replacement. Risks Improper use or maintenance can lead to connector damage, emphasizing the importance of proper use and maintenance. Adapters Compatible with many different hose types. The connector has a temperature resistance of +200°c Chemical resistance Made to withstand industrial chemicals, providing reliability and longevity. Certificates and classes Made in Germany, from high quality materials.

The Mold Quick Connector 9 mm tube is a high-quality, brass quick connector designed specifically for use in injection molding machines. This German-made connector offers excellent flow and is widely used in the industrial sector. Applications Injection molding machines, industrial equipment where excellent flow is required. Industries Industry, machine shops, manufacturing industry. Benefits The mold quick coupler provides excellent flow and is easy to connect with one hand, improving work efficiency. Risks Improper use or maintenance of the connector can lead to its damage, which emphasizes the importance of proper use and maintenance. Hoses Compatible with many different hoses suitable for mold cooling. Chemical resistance The mold quick connector is made of brass, which is very resistant to various chemicals. Certificates and classes Country of manufacture: Germany, Operating temperature: -20°C - +200°C, Profile: Female 9mm and male 13mm, Compatibility: HASCO Z80/9, HASCO Z801/9, RECTUS 10, DYROs. This mold quick connector is an excellent choice when you need a reliable, efficient and durable connector for industrial needs. Request a quote and learn more!

Nitrogen hose 30 Bar is a really strong hose, designed to withstand high pressures and heavy wear. This hose is a universal hose for demanding applications, which is also suitable for compression joints. Applications Nitrogen hose in industry and ships. Industries Chemical industry, construction industry, metal industry, food industry, ships and ports. Benefits Nitrogen hose 30 Bar is very durable and reliable, and has a long service life. The hose is electrically conductive (R<106 Ω). Risks As a result of misuse or insufficient maintenance, hoses can be damaged and cause accidents. Adapters Compatible with many different connectors. Chemical resistance The product is designed to withstand many different chemicals, which makes it very versatile. Operating temperatures -40 - +110 Operating pressure classes 30 bar / 90 bar Certificates and classes UNI EN ISO 1307/97 If you are interested in purchasing the Nitrogen Hose 30 Bar product, please contact us and request an offer. Our experts are ready to help you find the right solution for your needs.

Nitrogen hose 30 Bar is a really strong hose, designed to withstand high pressures and heavy wear. This hose is a universal hose for demanding applications, which is also suitable for compression joints. Applications Nitrogen hose in industry and ships. Industries Chemical industry, construction industry, metal industry, food industry, ships and ports. Benefits Nitrogen hose 30 Bar is very durable and reliable, and has a long service life. The hose is electrically conductive (R<106 Ω). Risks As a result of misuse or insufficient maintenance, hoses can be damaged and cause accidents. Adapters Compatible with many different connectors. Chemical resistance The product is designed to withstand many different chemicals, which makes it very versatile. Operating temperatures -40 - +110 Operating pressure classes 30 bar / 90 bar Certificates and classes UNI EN ISO 1307/97 If you are interested in purchasing the Nitrogen Hose 30 Bar product, please contact us and request an offer. Our experts are ready to help you find the right solution for your needs.

Nitrogen hose heavy duty is an industrial multipurpose tool designed to withstand even the most demanding conditions. This yellow, nitrogen marked hose is very versatile and compatible with many fittings. Its working pressure is 20 bar. Applications Nitrogen hose heavy duty is perfectly suited for industrial needs, such as the transfer of nitrogen gas, the transport of air and water in heavy use. Industries Nitrogen hose heavy duty is designed especially for the needs of industry, such as the construction industry, chemical industry, power plants and other industries that use nitrogen gas. Benefits Nitrogen hose heavy duty is a durable and versatile hose that offers excellent chemical resistance and is suitable for use in a wide temperature range. Risks Improper use or maintenance can lead to hose damage or leaks. It is important to follow the instructions given by the expert on the correct use and maintenance of the hose. Adapters Nitrogen hose heavy duty is compatible with many different fittings, including clamps and clamps. Chemical resistance Nitrogen hose heavy duty is made of yellow EPDM rubber, which offers excellent chemical resistance. Operating temperatures Nitrogen hose heavy duty is designed for use in a wide temperature range -30 °C to +80 °C. Operating pressure classes Nitrogen hose heavy duty is designed to withstand high operating pressures. You can get more detailed information about operating pressure classes by contacting our expert. Certificates and classes Nitrogen hose heavy duty complies with international nitrogen hose regulations. You can get more detailed information about certificates and classes by contacting our expert. If you need more information or would like to request a quote for the Nitrogen hose heavy duty product, contact our expert.

Nitrogen hose 20 Bar is a multipurpose industrial tool designed to withstand a pressure of up to 20 bar. The yellow hose marked with a stripe is made of high-quality EPDM material, which guarantees its longevity and reliability. Applications Nitrogen hose 20 Bar is excellently suitable as a nitrogen, air and water hose for heavy use. Industries The hose serves especially industrial sectors where the use of nitrogen, air or water hoses is common. Benefits Nitrogen hose 20 Bar offers a reliable and durable solution for industrial needs. Its versatility and high pressure resistance make it a valuable addition to the tool selection. hose conducting electricity <10⁶Ω, Risks As a result of misuse or neglect of maintenance, the hose can be damaged. Correct use and regular maintenance will extend the life of the hose and improve its performance. Adapters Nitrogen hose 20 Bar can be connected with clips or clamps. Chemical resistance A hose made of EPDM material is resistant to a wide variety of chemicals, which increases its possibilities of use. Operating temperatures Nitrogen hose 20 Bar withstands temperatures from -40 °C to +110 °C. Operating pressure classes The pressure resistance of the hose is 20 bar. Certificates and classes Nitrogen hose 20 Bar complies with international nitrogen hose regulations. Contact our expert to get more information about Nitrogen Hose 20 Bar or request a quote.

Safety hook automatic with locking for lifting 1.4 ton.

The threaded reducing fitting is a versatile and durable solution for industrial applications where a reduced thread is required. Made from high-quality brass, this fitting is ideal for handling compressed air, water and fuels. Its design allows for easy installation and reliable use in demanding conditions. This makes it an ideal choice for industrial professionals looking for an efficient and long-lasting fitting. Applications Compressed air, water, fuels Industries Industry, marine industry, engineering industry Benefits The threaded reduction fitting offers a reliable seal and a durable construction that reduces maintenance requirements. It is designed for long service life. Risks If installed incorrectly, the connector can cause leaks or pressure loss. It is important to ensure that the connector is installed correctly and is suitable for the application being used. Hoses Compatible with various compressed air and fuel hoses Chemical resistance The brass construction offers good resistance to many chemicals, but it is recommended to check compatibility individually. Operating temperatures -20 - +120°C Operating pressure classes 10bar / 25bar Certificates and classes No certificates mentioned

The threaded coupling is a premium low-pressure coupling with inch threads, designed specifically for industrial applications. Its durable material makes it an excellent choice for handling compressed air, fuels and water. This versatile coupling provides a reliable connection that can withstand even the most demanding conditions. The threaded coupling is easy to install and guarantees long-lasting performance. Applications Compressed air, fuels, water Industries Industry, engineering workshops, energy industry Benefits The threaded coupling provides a reliable connection and durable performance in a variety of industrial applications. It is easy to install and requires little maintenance. Risks If installed incorrectly, a threaded sleeve can cause leaks and reduce the functionality of the system. It is important to ensure proper installation and regular inspection. Hoses Compatible with most standard threaded hoses Chemical resistance The threaded sleeve is highly resistant to most common industrial chemicals, making it a versatile solution. Operating temperatures -20 - +80°C Operating pressure classes 6bar / 18bar Certificates and classes No specific certifications or classes mentioned

• Safety factor: 6 x nominal load • Standard: EN 13889 • Hot-dip galvanized • Operating temperature: -40°C – +200°C