The cross fitting with internal threads is a versatile and durable solution for industrial hose connections. Made of nickel-plated brass, this fitting offers excellent corrosion resistance and is particularly suitable for water, compressed air and fuels. Its internal threads allow for an easy and tight connection that will withstand even the most demanding conditions. This makes the cross fitting an ideal choice for industrial professionals looking for a reliable connection solution. Applications Water, compressed air, fuels Industries Industry, automotive, marine Benefits The cross connector with internal threads offers excellent durability and versatility, making it a reliable choice for various applications. Risks An incorrectly installed connector can cause leaks or pressure losses, which highlights the importance of professional installation. Chemical resistance Nickel-plated brass offers good chemical resistance, especially to water and fuels. Operating temperatures -20 - +100°C Operating pressure classes 6bar / 18bar

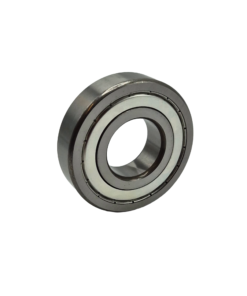

Deep groove ball bearing 6200 series c3 is designed to withstand even the most demanding industrial conditions. This bearing is part of the high-quality FAG 6200 series and has a C3 clearance, making it an excellent choice for heavy duty applications and high loads. Its design ensures reliable performance and a long service life, reducing maintenance requirements and improving the efficiency of production processes. Its compact size makes it easy to install in a variety of applications. Applications Motors, pump shafts, conveyor systems, industrial machinery Industries Automotive industry, mechanical engineering, food industry, paper industry Benefits Deep groove ball bearing 6200 series c3 offers excellent durability and reliability, which improves machine life and reduces downtime. Risks If installed incorrectly, bearing performance may be compromised, leading to increased wear and failure.

Loose Flange 150lbs AISI 304 DN20 - DN300 is a high quality connector designed for the demanding needs of industry. Made from durable AISI 304 stainless steel, it guarantees excellent durability and longevity. This loose flange is particularly suitable for high pressure situations, providing a reliable and safe connection. The compact and efficient design makes it an ideal choice for various industrial applications. Applications Process piping, steam lines, chemical industry systems Industries Oil and gas industry, chemical industry, food industry, power plants Benefits The loose flange provides a strong and durable connection that is highly resistant to corrosion and high temperatures. Chemical and corrosion resistance AISI 304 steel offers excellent protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing PTFE seals, graphite seals Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

Loose Flange 300lbs AISI 304 DN20 - DN300 is a high quality connector designed for the demanding needs of industry. This loose flange is made of durable AISI 304 stainless steel, which ensures excellent durability and longevity. Particularly suitable for high pressure situations, providing a reliable and safe connection. The compact and efficient design makes it an ideal choice for various industrial applications. Applications Process piping, steam lines, chemical industry systems Industries Oil and gas industry, chemical industry, food industry, power plants Benefits The loose flange provides a strong and durable connection that is highly resistant to corrosion and high temperatures. Chemical and corrosion resistance AISI 304 steel offers excellent protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing PTFE seals, graphite seals Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

Loose flange PN16 AISI 304 DN20 - DN300 is a durable and versatile fitting made of high-quality AISI 304 stainless steel. This fitting is ideal for use in various industrial applications where a reliable and long-lasting connection is required. The product's wide DN size range from DN20 to DN300 allows it to be used in a wide variety of piping configurations. The PN16 pressure rating makes it suitable for high pressure requirements. Applications Pipelines, tank connections, heating and cooling systems, industrial process piping Industries Chemical industry, food industry, oil and gas industry, water supply and wastewater management Benefits The PN16 AISI 304 flange offers excellent durability and a reliable connection for demanding applications in various industrial sectors. Stainless steel ensures good corrosion resistance and longevity. Chemical and corrosion resistance Made of AISI 304 stainless steel, the loose flange is highly resistant to a variety of chemicals and corrosion, making it an ideal choice for challenging environments. Sealing Suitable for use with PTFE and rubber O-rings, ensuring a tight connection. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

The removable flange PN26 AISI 304 DN20 - DN300 is a high-quality connector made of durable and corrosion-resistant AISI 304 stainless steel. It is designed specifically for industrial needs that require a reliable and long-lasting connection solution. The applications are especially pipelines that require easy installation and removal. Suitable for different sizes, covering a wide range from DN20 to DN300. Applications Pipelines, valves, tanks, pumps Industries Chemical industry, food industry, pharmaceutical industry, energy Benefits The removable flange offers easy and quick installation and disassembly, saving time and costs during maintenance operations. It is compatible with a variety of pipelines, making it a versatile solution. Chemical and corrosion resistance Made of AISI 304 stainless steel, which offers excellent resistance to chemicals and corrosion, extending the product's lifespan in demanding environments. Sealing Suitable for use with various seals, such as PTFE and rubber seals. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

Loose flange PN10 AISI 304 DN20 - DN300 is designed to provide a reliable and durable connection for industrial needs. Made of high quality AISI 304 stainless steel, this loose flange is very durable in demanding conditions. Its compatibility with pipes from DN20 to DN300 makes it a versatile solution for various connection needs. PN10 pressure resistance ensures safe and stable use in a wide range of applications. Applications Pipeline connection, water treatment systems, heating and cooling systems, chemical and process industries. Industries Industry, construction, energy, chemical industry. Benefits High quality AISI 304 steel ensures longevity and corrosion resistance. Versatile DN20 - DN300 compatibility allows use in various systems. Chemical and corrosion resistance AISI 304 steel offers good protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing Suitable seals include PTFE and rubber seals, which ensure a tight connection. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

The PN6 AISI 304 DN20 - DN300 loose flange is a high-quality connector designed specifically for the demanding needs of industry. Made of high-quality AISI 304 stainless steel, this loose flange offers excellent durability and reliability. It is compatible with pipes from DN20 to DN300, making it a versatile solution for various connection needs. The PN6 pressure resistance ensures safe and stable use in a wide range of applications. Applications Pipeline connection, water treatment systems, heating and cooling systems, chemical and process industries. Industries Industry, construction, energy, chemical industry. Benefits High quality AISI 304 steel ensures longevity and corrosion resistance. Versatile DN20 - DN300 compatibility allows use in various systems. Chemical and corrosion resistance AISI 304 steel offers good protection against most chemicals and corrosion, making it suitable for challenging environments. Sealing Suitable seals include PTFE and rubber seals, which ensure a tight connection. Finding the right size By measuring the outer or inner diameter of the flange with a caliper, you can easily check the correct connector size using the thread table below.

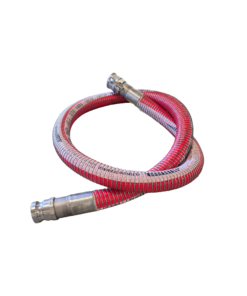

Composite hose 2" female saflok is designed to withstand demanding industrial conditions where reliability and chemical resistance are key. Its durable and flexible construction ensures easy connection and quick installation, making it an ideal choice for professionals. The hose is equipped with 2" camlock fittings, which allow for smooth connection to various systems. The Teflon inner surface ensures excellent chemical resistance, expanding the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Teflon coating inside the hose ensures excellent chemical resistance. Acid-resistant safety locking Saflok cam lever connector ensures the safety of the pressurized hose. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female saflok is designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible construction makes handling and installation easy. Acid-resistant camlocks ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose has a Teflon membrane on the inside and acid-resistant connectors. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 3" male threads are designed for the demanding needs of industrial chemical transfer, offering excellent durability and versatility in various conditions. This hose is made of high-quality materials, ensuring long service life and reliable performance. The 3 inch composite hose with acid-resistant male threads is easy to connect and install, making it an ideal choice for industrial professionals. The Teflon inner surface of the hose provides a wide range of chemical resistance. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The composite construction offers lightness and flexibility, making the hose easy to handle and install. The high-quality materials ensure excellent durability in demanding industrial environments. Risks Although the hose is designed to withstand a variety of chemicals, improper or excessive pressure can cause damage. It is important to ensure that the hose is installed correctly and used within the recommended operating conditions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose is highly resistant to a wide range of chemicals, making it ideal for demanding industrial applications. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes Hoses are manufactured and tested according to EN 13765 - IMO IBC code.

Deep groove ball bearing 6300 series 2ZR is a high-quality bearing equipped with a durable metal shield. This bearing offers reliability and long service life in various industrial applications. It is designed to withstand demanding conditions and effectively reduce friction. The metal shield protects the bearing from dust and other contaminants, making it an excellent choice for demanding environments. Applications Industrial equipment, conveyor belts, electric motors, pumps Industries Automotive, manufacturing, energy, engineering Benefits Deep groove ball bearing 6300 series 2ZR offers excellent durability and performance, reducing the need for maintenance and improving equipment reliability. Risks Although the bearing is protected by a metal shield, its service life may be shortened if it is continuously exposed to extreme temperatures or humidity.

Deep groove ball bearing 6300 series 2ZR is a high-quality bearing equipped with a durable metal shield. This bearing offers reliability and long service life in various industrial applications. It is designed to withstand demanding conditions and effectively reduce friction. The metal shield protects the bearing from dust and other contaminants, making it an excellent choice for demanding environments. Applications Industrial equipment, conveyor belts, electric motors, pumps Industries Automotive, manufacturing, energy, engineering Benefits Deep groove ball bearing 6300 series 2ZR offers excellent durability and performance, reducing the need for maintenance and improving equipment reliability. Risks Although the bearing is protected by a metal shield, its service life may be shortened if it is continuously exposed to extreme temperatures or humidity.

Tapered roller bearing 30300 series is designed to provide reliable performance in various industrial applications. This bearing series is specially developed to withstand heavy loads and demanding operating conditions, making it an ideal choice for industrial applications. Its innovative design allows for effective lubrication and low friction, which extends the bearing's service life. The precise manufacturing process of the tapered roller bearing guarantees its reliability and quality. Applications Industrial equipment, mechanical engineering, conveyor lines, power transmission systems. Industries Metal industry, mining industry, automotive industry, energy production. Benefits The 30300 series tapered roller bearing offers long-life performance and reduced maintenance under heavy loads. Its precise and durable design enables reliable operation in demanding industrial environments. Risks If installed or maintained incorrectly, the service life of the bearing can be significantly reduced. In addition, the ingress of contaminants into the bearing can cause malfunctions and damage. Chemical resistance The tapered roller bearing is resistant to most industrial lubricants and solvents, but it is recommended to check compatibility with specific chemicals.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.