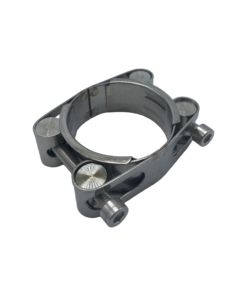

Hose clamp stainless The affordable clamp for coolant hose is a high-quality hose clamp made of AISI 304 stainless steel, which offers a reliable and durable solution for coolant hose assemblies. This clamp, which complies with the DIN 3017 standard, ensures safe and effective fastening with a 6 mm hexagon bolt. It is designed to withstand high pressures and temperatures, making it an ideal choice for engine coolant systems. Its ease of use and quick installation also make it a suitable choice for home use. Applications Machines, engines and equipment. Industries Boat manufacturing, vehicle industry, machinery and equipment maintenance. Benefits Durable and secure clamp provides reliable fastening in demanding conditions. Easy installation saves time and effort. Risks Tightening too much can damage the hose or the clamp. If installed incorrectly, the clamp will not achieve optimal tension. Chemical resistance Stainless AISI 304 material offers good protection against most chemicals, but is not suitable for all highly corrosive environments. Operating temperatures -40 - +120 Operating pressure classes 5 bar / 15 bar Certificates and classes DIN 3017 The clamp should be selected so that the size is as close as possible to the outer diameter of the hose, preferably the same. Size = Clamp clamping area.

The PARI clamp AISI 316 is a durable and safe connection solution for industrial hoses. Its acid-resistant properties ensure reliable fastening in areas where there is a high risk of corrosion and rusting. With the help of two bolts, the clamp attaches evenly around the hose and stays firmly in place. Applications Pipelines, boats, ships, airplanes, fixing metal parts of buildings. Industries Industry, shipbuilding, aviation, construction industry. Benefits The PARI tensioner reduces the need for maintenance and extends the life of the equipment. Its use is safe and durable. Risks Improper installation or maintenance can lead to damage to the tensioner and thus equipment malfunctions. Chemical resistance Acid-resistant steel is resistant to various chemicals, which increases the life and safety of the product. Operating temperatures -40 - +120 Contact our experts, and we will help you find the perfect PARI tensioner for your needs.

Fuel/oil hose 10bar is a reliable and durable choice for industrial needs. Its reinforced structure and excellent chemical resistance make it an ideal choice for handling both fuels and oils. Applications Machinery, equipment, oil and fuel transfer. Industries Industry, workshops, warehouses. Benefits The hose's excellent chemical resistance and reinforced structure guarantee a long service life and reliability. Risks Improper use or maintenance can lead to hose damage and leaks. Adapters Compatible with many standard connectors. Chemical resistance Aromatic resistance 50%, excellent for oils and other hydrocarbons. Operating temperatures -35 °C to +90 °C Operating pressure classes 10 bar Contact us to get an offer for the Fuel/oil hose 10 bar product.

The PARI hose clamp is an industrial credit product that offers a durable and safe connection method for industrial hoses. It is designed to withstand vibration, corrosion and moisture, making it extremely reliable. Applications Pipelines, boats, ships, fixing metal parts of buildings. Industries Industry, shipping, construction industry, mechanical engineering. Benefits The PARI hose clamp reduces the need for maintenance and extends the service life of the equipment, offering a reliable and safe connection method. Risks Improper installation or maintenance can result in tensioner damage and hose separation, so proper use and maintenance are important. Adapters The PARI hose clamp is compatible with many different hoses, offering a wide range of usage possibilities. Chemical resistance The PARI hose clamp is designed to withstand chemical stresses, offering a long-lasting solution for industrial needs. Operating temperatures -40 - +120 If you need help choosing the right tensioner, feel free to contact us. We help you find the best solution for your needs.

Rubber sanitary hose is a top-class product, specially designed for waste water pipes in boat toilet systems. Made from high-quality materials, this hose guarantees longevity and reliability. Its highly flexible design effectively prevents the spread of unpleasant odors from the toilet, making it an ideal choice for boat building. Applications Boat toilet systems, waste water pipes. Industries Marine industry, boat building, sanitary supplies. Benefits This sanitary hose offers longevity and reliability, and keeps toilets odor-free. Risks Improper installation or maintenance can reduce the life and efficiency of the hose. Hoses Compatible with many different toilet systems. Chemical resistance The hose is resistant to ozone, UV radiation and salt water. Operating temperatures -40 - +100. Certificates and classes EUROPEAN FDA, ISO 8099 : 2000.

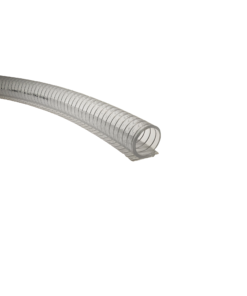

The transparent bilge suction hose is designed for draining the bilge of boats, offering excellent durability and transparency, making it easy to monitor the flow. This PVC suction hose is equipped with a steel spiral, which allows the hose to be flexible and durable at sharp angles. Its transparent design makes it the ideal choice when it is necessary to monitor the flow of liquids. Optimal for clamp connections, the hose provides a reliable and durable connection in various applications. Applications Pump suction hose, pressure hose for low pressures. As a bilge hose for boats. Industries Industry, food industry, chemical industry, boat building. Benefits The PVC suction hose is a durable and reliable solution that meets the requirements of the EU 10/2011 A, B, C food quality standard. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Adapters Compatible with various types of clamp connections. Chemical resistance Made to withstand various industrial chemicals, our hoses offer reliability and longevity. Certificates and classes EU 10/2011 A, B, C food quality standard.

The bilge suction hose is designed to provide a flexible and durable solution for boats. This hose is especially good for boat piping, where its extreme flexibility and durability come into play. The bilge suction hose is compatible with a variety of standard fittings, making it a versatile choice for a variety of applications. Its durable construction ensures reliable use and longevity. Applications Confined spaces, fuel hoses, bilge, oil return hoses, refueling hoses for boats and equipment. Industries Industry, shipping, boatbuilding. Benefits The extreme flexibility of the bilge suction hose allows it to be used in confined spaces, and its durable construction ensures a long service life. Risks Improper installation or maintenance can lead to hose damage and leaks, so proper use and maintenance is important. Adapters Compatible with many standard connectors. Chemical resistance Made to withstand various chemicals, which guarantees the longevity of the product. Operating temperatures -35 °C/+100 °C Operating pressure classes 5 bar / 15 bar Contact us and request a quote for a bilge suction hose. Our experts will be happy to help you choose the right solution for your needs.

The 95mm shaft seal is designed to provide reliable sealing in demanding industrial environments. Made from high-quality oil-resistant NBR rubber and equipped with a steel spring, it offers exceptional durability and performance. The seal has an inner diameter of 95 mm, making it an ideal choice for a variety of industrial equipment. It allows you to ensure long-lasting and trouble-free operation of your equipment. Applications Shafts, industrial machinery, pumps, motors Industries Mechanical engineering, automotive industry, marine industry, energy industry Benefits The shaft seal significantly reduces the risk of leakage and extends the service life of the equipment, resulting in lower maintenance costs. Risks An incorrectly installed gasket can cause leaks and damage the equipment, so correct sizing and installation are essential. Chemical resistance NBR rubber offers good resistance to oils and greases, but is not suitable for strongly oxidizing chemicals. Operating temperatures -40 - +100°C

The 95mm shaft seal is designed to provide optimal protection and durability for industrial applications. This high-quality seal effectively prevents oil and other fluids from leaking, extending the life of your equipment and improving its performance. The shaft seal is made of top-quality materials, making it an excellent choice for demanding industrial environments. It is easy to install and maintain, saving time and money. Applications Rotating shafts, motors, pumps, gearboxes Industries Mechanical engineering, automotive industry, chemical industry, energy industry Benefits The shaft seal significantly reduces maintenance costs and effectively prevents leaks, which improves the reliability and safety of the equipment. Risks If installed incorrectly, the gasket can cause leaks or equipment malfunctions. It is important to select the correct gasket material based on chemical and thermal conditions.

The shaft seal for 8mm shaft is designed to ensure reliable sealing and prevent leakage of liquid or gaseous media through shafts. This radial shaft seal offers a durable solution for demanding industrial needs. Made of high-quality materials, it is resistant to wear and tear and extends the service life of equipment. Easy installation and maintenance make it an excellent choice for a variety of applications. Applications Mechanical engineering, pumps, compressors, industrial equipment Industries Marine, oil and gas industry, chemical industry, food industry Benefits Provides excellent sealing and reduces the need for maintenance, saving time and costs. Risks If installed incorrectly, it can cause leaks and equipment damage, highlighting the importance of professional installation. Chemical resistance It is highly resistant to a variety of industrial chemicals, making it a versatile choice for a variety of environments. Operating temperatures -50 - +120°C

The 7mm shaft seal is designed to provide reliable sealing in demanding industrial applications. This radial shaft seal effectively prevents leaks, which extends the life of the equipment and reduces the need for maintenance. Its durable construction and precise design make it suitable for many industrial environments. Easy installation and wide compatibility make it a versatile solution. Applications Hydraulic systems, pumps, motors, gearboxes Industries Marine, mining, oil and gas industry, food industry, chemical industry Benefits Reduces the risk of leaks and improves equipment efficiency, leading to lower maintenance costs and longer service life. Risks Incorrect installation can lead to leaks, and incorrectly selected sealing material can deteriorate when exposed to chemicals. Chemical resistance Suitable for use with many chemicals, but it is recommended to check compatibility with specific substances. Operating temperatures -20 - +100 Operating pressure classes 5 bar / 15 bar Certificates and classes NO certificates mentioned

The shaft seal for 5mm shaft is specially designed to provide a durable and reliable solution for industrial needs. This radial shaft seal is equipped with a sealing lip that ensures maximum tightness and protects the shaft effectively. Made of durable NBR rubber and steel spring, the seal offers a long-lasting solution in demanding environments. The compact design allows for easy installation and versatile use in various industrial applications. Applications Hydraulic systems, pumps, motors, gearboxes Industries Mechanical engineering, automotive industry, marine industry, energy industry Benefits The 5mm shaft seal provides excellent protection against dust and dirt, which extends the life of the equipment and reduces maintenance costs. Risks An incorrectly installed gasket can cause leaks and damage to the equipment, so proper installation is of paramount importance. Chemical resistance NBR rubber offers good chemical resistance in most industrial environments. Operating temperatures -30 - +100°C

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

SAE flange coupling 6000psi 90° Aisi 316 is designed to provide a reliable connection in hydraulic systems where high pressure and angle connection are required. This flange coupling is especially suitable for demanding industrial needs where safety and durability are a priority. Made from high quality materials, it is highly resistant to wear and tear and provides a long-lasting solution. Easy to install and use, this coupling improves system performance and reduces maintenance costs. Applications Hydraulic systems, industrial equipment, heavy machinery, transportation equipment Industries Construction, mining, agriculture, transportation, energy Benefits Provides excellent pressure resistance and ensures safe operation in high-pressure applications. Reduces the risk of system leaks and improves overall efficiency. Risks Incorrect installation may cause leaks or system malfunctions. Incompatible components may reduce the durability of the connection. Hoses Compatible with many high-pressure hydraulic hoses, such as Parker 43 series and Gates Global MegaSys. Chemical resistance Resistant to many common industrial chemicals, but it is recommended to check compatibility before use. Operating temperatures -50°C - +180°C Operating pressure classes Hydraulic pressures Certificates and classes SAE J518, ISO 6162

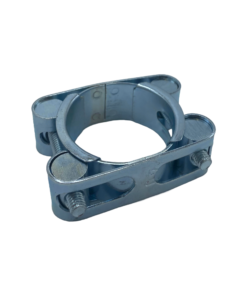

The hose clamp for rubber and plastic hoses is designed to provide a reliable and durable solution for industrial needs. This high-quality hose clamp ensures a secure hold for both rubber and plastic hoses, reducing hose movement and wear. The easy-to-use and convenient-to-install hose clamp is suitable for a wide range of industrial environments. Its compact design allows for flexible use in a variety of applications. Applications Rubber and plastic hoses, industrial equipment, machinery Industries Industry, machine shops, production plants Benefits The hose clamp provides a stable and secure attachment, which extends the life of the hoses and reduces maintenance costs. Risks If installed incorrectly, a hose clamp can cause hose damage or leaks, so careful installation is important. Hose clamps that are the wrong size can also weaken the connection and increase the risk of breakage. Hoses Suitable for commonly used rubber and plastic hoses Chemical resistance The hose clamp is made of materials that are resistant to most chemicals used in industry. Operating temperatures -20 - +80 Operating pressure classes 5 bar / 15 bar Certificates and classes ISO 9001, CE marked

The hose clamp for rubber and plastic hoses is designed to provide a reliable and durable solution for industrial needs. This high-quality hose clamp ensures a secure hold for both rubber and plastic hoses, reducing hose movement and wear. The easy-to-use and convenient-to-install hose clamp is suitable for a wide range of industrial environments. Its compact design allows for flexible use in a variety of applications. Applications Rubber and plastic hoses, industrial equipment, machinery Industries Industry, machine shops, production plants Benefits The hose clamp provides a stable and secure attachment, which extends the life of the hoses and reduces maintenance costs. Risks If installed incorrectly, a hose clamp can cause hose damage or leaks, so careful installation is important. Hose clamps that are the wrong size can also weaken the connection and increase the risk of breakage. Hoses Suitable for commonly used rubber and plastic hoses Chemical resistance The hose clamp is made of materials that are resistant to most chemicals used in industry. Operating temperatures -20 - +80 Operating pressure classes 5 bar / 15 bar Certificates and classes ISO 9001, CE marked

Acid-resistant SAE straight flange connector for 6000PSI hydraulic hose.