Don't take the risk of using inferior brake hoses when you can rely on reliable and performance-enhancing brake hoses manufactured by the official distributor of HEL Performance, which are handcrafted in Porvoo. Most competitors use galvanized fittings that are prone to corrosion - our hoses and fittings are always made of stainless steel, which are durable. Our brake hose master has manufactured tens of thousands of brake hoses over the years, so you can always drive your car with confidence that your brake hoses are of high quality. This set contains a total of 3 hoses, so for only 85.05 euros you are guaranteed to get value for your money.

KRÄNZLE PROFI 175 TST 175BAR 400V 12L/MIN 1400rpm

• Safety factor: 6 x nominal load • Standard: EN 13889 • Hot-dip galvanized • Operating temperature: -40°C – +200°C

Pressure nozzle 25ast 1/6

The crowbar is specially designed for the nut driver, providing an efficient and reliable tool for industrial professionals. This product is made of high-quality materials that ensure long service life and durability in demanding conditions. Its ergonomic design allows for easy and safe use, reducing fatigue and improving work efficiency. The crowbar is the ideal solution when precise and powerful torque is required. Applications Industrial plants, maintenance and repair work, assembly lines, heavy machinery Industries Automotive industry, engineering industry, construction industry, marine industry Benefits The crowbar offers excellent torque, which improves work efficiency and reduces work time. Its durable construction ensures longevity and reliability in demanding applications.

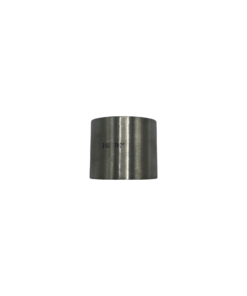

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar