The acid-resistant pressure washer connector is designed to withstand demanding industrial conditions, providing a reliable and long-lasting solution to various connection challenges. This connector is made of high-quality AISI 316 stainless steel, which ensures excellent corrosion resistance even in chemically challenging environments. Applications Pressure washer hose connection. Industries Industry, mechanical engineering, energy sector, industrial and household needs in washing. Benefits Provides a reliable and long-lasting solution for demanding applications. Easily connects to DIN 2353 pipe fittings, ensuring versatility. Chemical and corrosion resistance Heavy-duty connectors are made of high-quality materials that are highly resistant to chemicals and corrosion. Sealing The connector seals easily to the mating part as long as the O-ring is intact. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

TW male connector with acid-resistant hose reel 3". Hose connection with clamps or compression with a sleeve Model: VKST Norm: DIN EN 14420-6

TW female connector with acid-resistant hose reel 3". Hose connection with clamps or compression with sleeve Model: MKST Norm: DIN EN 14420-6 Seal: Hypalon

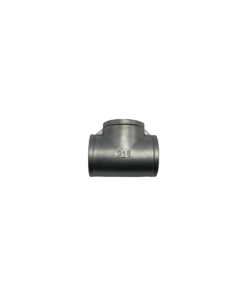

The HST T-connector with internal threads is designed to provide a reliable and long-lasting solution for industrial needs. Made of high-quality acid-resistant steel. Its internal thread profile ensures easy and tight installation, which reduces the risk of leaks and improves efficiency. The compact design allows for versatile use and easy integration into existing systems. Applications Pipeline connections, compressed air systems, water distribution networks, industrial process piping Industries Mechanical engineering, chemical industry, food industry, oil and gas industry Benefits The HST T-connector with internal threads offers excellent tightness and durability, minimizing the need for maintenance and improving system reliability. Chemical and corrosion resistance This connector is designed to withstand harsh chemical environments and prevent corrosion, extending its service life and reducing maintenance requirements. Sealing The connector is preferably sealed on the thread with thread sealant, which also lubricates the thread during the fastening phase, preventing it from seizing. Acid-resistant material requires an activator to accompany the thread sealant. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.