Seamless hydraulic tubing is designed to withstand high pressure and provide reliable performance in demanding industrial environments. Its seamless construction is particularly appreciated for its durability and minimizing the risk of leakage, making it an ideal choice for critical applications. The low-friction inner surface ensures efficient fluid flow, which improves the energy efficiency of the system. This product is made of high-quality materials that ensure a long service life and low maintenance costs. Applications hydraulic systems, industrial and production plants, machine shops, heavy machinery Industries manufacturing industry, construction industry, maritime industry, transportation and logistics Benefits Seamless construction reduces the risk of leaks and optimizes system reliability. Durable material and construction extend service life and reduce maintenance. Risks Incorrect installation or overloading of hydraulic lines can lead to system failure. Regular inspection and correct installation are essential to ensure safe operation. Chemical resistance It is highly resistant to most industrial chemicals and hydraulic fluids, making it a versatile choice for a variety of applications.

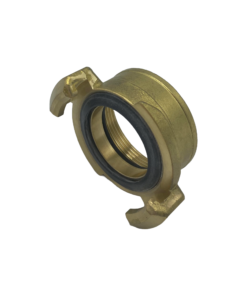

The brass fire connector is a high-quality connector specially designed for the diverse needs of industry. Its lightweight yet durable construction makes it an ideal choice for submersible pump use and other demanding applications. Equipped with an external thread and sealing ring, it ensures a reliable connection and longevity in various hose systems. Available with different claw spacing sizes, allowing for precise and safe installation. Applications Industrial plants, fire hydrants, submersible pumps, hose systems Industries Firefighting, industry, construction, water supply Benefits The fire hose connector offers a combination of lightness and durability, which facilitates installation and extends the product's service life. It ensures a reliable connection and reduces the risk of leaks. Risks An incorrectly selected connector size can cause leaks and an unreliable connection, which can lead to damage and downtime. It is important to check the gap carefully before installation. Hoses Compatible with fire hydrant hoses, submersible pump hoses and other industrial hoses Chemical resistance The hose connector of the fire connector is resistant to many chemicals used in industry, but it is recommended to check compatibility before use. Operating temperatures -20 to +80°C Operating pressure classes 10bar / 16bar Certificates and classes Made in Finland

The ultra-light output connector is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made of high-quality materials, ensuring its lightness and easy handling without compromising on durability. The ultra-light output connector is ideal for versatile installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-light output connector offers quick installation and low maintenance, which reduces operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-light output connector is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The ultra-light output connector is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made of high-quality materials, ensuring its lightness and easy handling without compromising on durability. The ultra-light output connector is ideal for versatile installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-light output connector offers quick installation and low maintenance, which reduces operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-light output connector is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The ultra-light nut is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made from high-quality materials, ensuring its lightness and ease of handling without compromising on durability. The ultra-light nut is ideal for a variety of installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-lightweight nut offers quick installation and low maintenance, reducing operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-lightweight nut is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The ultra-light extension connector is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made of high-quality materials, ensuring its lightness and easy handling without compromising on durability. The ultra-light extension connector is ideal for versatile installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-light extension connector offers quick installation and low maintenance, which reduces operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-light extension connector is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The Fire Connector Internal Thread Brass is a high-quality connector designed to withstand demanding conditions. Made of aluminum, it is lightweight yet durable, making it an excellent choice for a variety of water and fire hydrant applications. Its internal thread and sealing ring ensure a reliable connection and easy installation. Careful measurement of the claw gap ensures optimal operation. Applications Fire hydrants, submersible pumps, water lines, pumps. Suitable for suction and pressure. Industries Industry, construction, municipal engineering Benefits The internal thread of the fire connector is lightweight and durable, making it easy to handle and install. It provides a reliable connection that can withstand even the most demanding operating conditions. Risks Choosing the wrong nail spacing can lead to loosening or leakage of the joint. Careful sizing and choosing the right size are essential to ensure safe use. Hoses Compatible connectors include standard-sized fire connectors and water line connectors. Chemical resistance The aluminum construction offers good corrosion resistance, but is not suitable for strongly acidic or alkaline environments. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar

The brass conversion fire connector is designed to facilitate the efficient connection of hoses of different sizes. This durable and reliable connector reduces installation time and improves work flow. If necessary, our experts can manufacture customized conversions for different connectors. Remember to check the claw spacing to ensure the correct size. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with a variety of industrial hoses, including 2", 3" and 4" connectors. Chemical resistance The brass construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The Palolitt diverter valve is designed for efficient and reliable hose branching in industrial applications. Made of high-quality Finnish aluminum, it combines the advantages of gate valves and ball valves. This diverter offers a durable solution that allows two hose lines to be connected to a main line. Available in two different models, it meets a variety of industrial needs. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with many industrial hoses and fire fittings. Chemical resistance The aluminum construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The aluminum fire connector conversion is designed to make it easier to fit connections between different sizes of hoses. This durable and reliable connector allows you to effectively reduce the connection size, which reduces installation time and improves workflow. If necessary, our experts can manufacture customized conversions for different connectors. Remember to check the claw spacing to ensure the correct size. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with a variety of industrial hoses, including 2", 3" and 4" connectors. Chemical resistance The aluminum construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

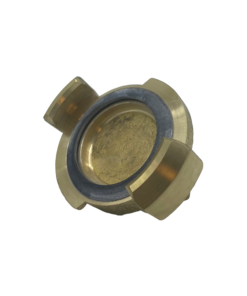

The brass fire connector plug is designed to provide a reliable and durable solution for demanding industrial needs. Its lightweight and durable construction makes it an ideal choice for submersible pumps, water lines and other industrial systems. The sealing ring ensures a tight connection, making it an excellent choice for critical systems. This product is widely used in Finnish fire hydrants, which highlights its suitability for fire safety. Applications Submersible pumps, water lines, fire hydrants, industrial systems Industries Industry, municipal engineering, fire safety Benefits The brass fire connector plug offers a lightweight yet durable solution for industrial needs, ensuring a tight and reliable connection. Its aluminum construction allows for easy handling and installation. Risks Selecting the wrong size can lead to leakage or unreliable connections. It is important to ensure the correct gap and compatibility of the connector with the application. Chemical resistance The aluminum construction is highly resistant to most chemicals used in industry, but it is recommended to check specific chemical cases before use. Operating temperatures -20 to +80°C Operating pressure classes 5bar / 16bar

The aluminum hose connector is designed to provide a reliable and durable solution for industrial needs. Made from high-quality aluminum, it combines lightness with excellent durability. The connector design allows for easy installation and ensures a tight connection. It is the ideal choice when you are looking for a long-lasting and efficient connector for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The aluminum hose connector provides a lightweight yet durable connection that can withstand harsh industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector can cause leaks or impair the function of the hose system. It is important to ensure that the connector is compatible with the hose being used. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The aluminum hose connector is designed to withstand a variety of industrial chemicals, but is not recommended for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar

Brass hose connector female thread is designed to meet the demanding industry standards. Made from high quality brass, this connector offers excellent durability and performance. Easy installation and a tight connection ensure reliable operation in a wide range of applications. The brass construction makes it a long-lasting and efficient solution for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The brass hose connector provides a durable connection that performs reliably in demanding industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector may cause leaks or impair system performance. Compatibility with the hose being used must be ensured. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The brass hose connector is resistant to many industrial chemicals, but is not suitable for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar Certificates and classes Fire connector used in Finland

The aluminum hose connector with internal thread is designed to meet the demanding needs of industry. Made from high-quality aluminum, this connector combines lightness and durability, making it an ideal choice for many applications. Easy installation and a tight connection ensure reliable operation. This connector is a long-lasting and efficient solution that is ideal for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The aluminum hose connector provides a lightweight yet durable connection that can withstand harsh industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector can cause leaks or impair the function of the hose system. It is important to ensure that the connector is compatible with the hose being used. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The aluminum hose connector is designed to withstand a variety of industrial chemicals, but is not recommended for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar

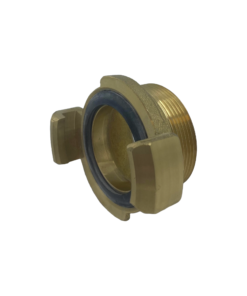

The brass fire connector male thread is designed specifically for industrial needs, providing a reliable and durable solution for various water lines and submersible pump applications. Its lightweight aluminum construction and male thread make it easy to handle and install. The sealing ring ensures a tight connection, which increases the versatility and application possibilities of the product. This connector type is commonly used in Finnish fire hydrants, which emphasizes its reliability and practicality. Applications water lines, submersible pumps, fire hydrants Industries industry, municipal engineering, fire protection Benefits The external thread of the fire connector offers a lightweight yet durable solution that allows for quick and easy installation. Its versatility makes it suitable for a variety of applications. Risks An incorrect fitting size can cause leaks or joint failure, so ensuring the correct size is important. Expert selection is the key to safe and efficient use. Chemical resistance The aluminum construction offers good resistance to most water and firefighting chemicals. Operating temperatures -20 - +80 Operating pressure classes 10bar / 16bar

The brass T-fitting male/female/female is a sturdy and durable solution for industrial hose systems. This fitting is specifically designed to connect male and female threads reliably and tightly. Its brass construction ensures excellent durability and longevity even in demanding conditions. Easy installation and versatile use options make it an ideal choice for various industrial applications. Applications Industrial plants, piping, hydraulic systems, pneumatic systems Industries Oil and gas industry, chemical industry, food industry, engineering industry Benefits The brass T-fitting offers excellent tightness and durability, reducing the risk of leaks and extending the life of the system. Its versatility and easy installation make it a cost-effective choice. Risks Although the brass T-fitting is durable, it can be subject to corrosion in extreme chemical environments. Regular inspection and maintenance are recommended to minimize the risk of leaks. Hoses Compatible connectors: BSP threaded connectors, NPT threaded connectors Chemical resistance Brass is highly resistant to many chemicals, but it is recommended to check compatibility, especially with strong acids. Operating temperatures -20 - +120°C Operating pressure classes 10 bar / 30 bar Certificates and classes No certifications or classes mentioned.

Brass T-fitting sk/uk/sk is a high-quality component made of nickel-plated brass, offering excellent durability and reliability for demanding industrial applications. This fitting is specifically designed for water and compressed air handling, ensuring efficient and safe use. Its versatile design allows for easy integration into various systems, making it an ideal choice for industrial professionals. High-quality materials and a precise manufacturing process ensure a long service life and low maintenance. Applications Water and compressed air systems, industrial piping, machine and equipment connections, hydraulic systems Industries Industry, mechanical engineering, automation, energy sector Benefits The brass T-fitting offers excellent durability and reliability, reducing downtime and maintenance costs. Its versatility and compatibility make it ideal for a variety of industrial applications. Risks If installed incorrectly, the connector can cause leaks and pressure losses, which can lead to system malfunctions. It is important to ensure that the connector is installed correctly and that its compatibility with other components has been checked. Hoses Compatible with hoses manufactured to multiple standards, such as PVC hoses, rubber hoses, polyurethane hoses Chemical resistance Nickel-plated brass offers good resistance to most chemicals found in water and compressed air, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 10 bar / 30 bar

The brass T-fitting with internal threads is designed to provide a reliable and durable solution for industrial needs. Made of high-quality brass, this fitting is an ideal choice for situations where durability and reliability are required. Its internal threads allow for easy and secure attachment to various systems. Thanks to its brass material, it is excellently suited for handling water and compressed air. Applications Water and compressed air systems, industrial piping, hydraulic applications, air conditioning systems Industries Industry, construction, energy, chemical industry Benefits The brass T-fitting offers excellent durability and longevity in demanding conditions. Its easy installation and versatility make it a cost-effective solution. Risks From an expert's perspective, an incorrectly selected connector can cause leaks or system malfunctions. It is important to ensure that the connector is compatible with other system components. Hoses Compatible hoses: PVC hoses, rubber hoses, polyurethane hoses Chemical resistance The brass fitting is highly resistant to most chemicals used in industry, but check compatibility with specific chemicals before use. Operating temperatures -40 - +100°C Operating pressure classes 10bar / 25bar