Epdm hose 10bar is an excellent choice for various industrial needs. This heat-resistant hose is suitable for both suction and pressure hose use, and its wear-resistant outer surface guarantees longevity. Applications Suction and pressure hose use, various industrial needs. Industries Industry, construction, agriculture, chemical industry, process industry. Benefits EPDM hose is heat-resistant +120°C and wear-resistant, which makes it a long-lasting and reliable choice. Risks Improper use or maintenance can lead to hose damage. Correct use and maintenance are important for the hose's longevity. Adapters EPDM hose is compatible with many different fittings. Chemical resistance EPDM hose is made to withstand a wide range of chemicals, which makes it a reliable choice for various applications. Request a quote for this reliable and long-lasting EPDM hose designed to meet the various needs of industry.

Chemical hose PTFE 16bar corrugated is a top-class solution for industrial chemical handling. This Teflon rubber hose is specially designed for the safe transfer and storage of hazardous chemicals, such as acids and alkalis. Its corrugated structure offers flexibility and durability, which allows for demanding operating conditions. High chemical and heat resistance make the hose a reliable partner for industrial needs. Applications The hose can be used especially in demanding areas of industry, such as the transfer and storage of chemicals. Industries Chemical industry, metallurgy, agriculture, food industry. Benefits Chemical hose PTFE 16bar offers excellent chemical resistance and heat resistance, which makes it a long-lasting and reliable solution. Risks Improper handling or maintenance can damage the hose and cause leaks, so we recommend that you strictly follow the use and maintenance instructions. Adapters Compatible connectors are, for example, clamp connectors. Chemical resistance The hose is made of PTFE / Teflon material, which is excellently resistant to various chemicals. Operating temperatures -30 °C to +150 °C Operating pressure classes Working pressure 16 bar, burst pressure 48 bar. Certificates and classes EN 12115:2011, EN 1761, TRbf 131/2 Contact our hose specialist for more information or to request a quote for Chemical hose PTFE 16bar.

Chemical hose 30 Bar is designed to withstand high pressures and wear, which makes it an excellent choice for demanding applications. The hose is a very general-purpose EPDM rubber hose that is suitable for many different chemicals. Applications The chemical hose 30 Bar is the ideal universal hose in industry. Industries The hose is perfectly suited for use in the chemical industry, construction industry, metal industry, food industry, and in ships and ports. Benefits Chemical hose 30 Bar is very durable and reliable, and its fabric-reinforced construction makes it a reliable choice for the chemical industry. In addition, the hose is electrically conductive (R<106 Ω). Risks Like all hoses, the Chemical Hose 30 Bar can also be damaged as a result of misuse or insufficient maintenance, in which case it may cause accidents. Adapters Chemical hose 30 Bar is compatible with several different connectors and is also well suited for compression joints. Chemical resistance The hose is designed to withstand many different chemicals, making it very versatile. Operating temperatures -40 - +110 Operating pressure classes 30 bar / 90 bar Certificates and classes UNI EN ISO 1307/97 If Chemical Hose 30 Bar seems like a suitable product for your needs, please contact us and request an offer. Our experts are ready to help you find the best solution for your needs.

Chemical hose 30 Bar is designed to withstand high pressures and wear, which makes it an excellent choice for demanding applications. The hose is a very general-purpose EPDM rubber hose that is suitable for many different chemicals. Applications The chemical hose 30 Bar is the ideal universal hose in industry. Industries The hose is perfectly suited for use in the chemical industry, construction industry, metal industry, food industry, and in ships and ports. Benefits Chemical hose 30 Bar is very durable and reliable, and its fabric-reinforced construction makes it a reliable choice for the chemical industry. In addition, the hose is electrically conductive (R<106 Ω). Risks Like all hoses, the Chemical Hose 30 Bar can also be damaged as a result of misuse or insufficient maintenance, in which case it may cause accidents. Adapters Chemical hose 30 Bar is compatible with several different connectors and is also well suited for compression joints. Chemical resistance The hose is designed to withstand many different chemicals, making it very versatile. Operating temperatures -40 - +110 Operating pressure classes 30 bar / 90 bar Certificates and classes UNI EN ISO 1307/97 If Chemical Hose 30 Bar seems like a suitable product for your needs, please contact us and request an offer. Our experts are ready to help you find the best solution for your needs.

Stainless external thread 3/8" brake connector steel braid for brake hose.

This stainless steel braided hose male thread 45 degree angle brake connector is an excellent solution for brake system connections. Its unique design allows the connection to be made at an angle of 45 degrees, which is an ideal solution when the brake connector needs to turn at a gentle angle. This brake coupler's compression male thread ensures a perfect fit with steel braided hose, and its stainless steel construction ensures longevity. In addition, it is easy to install and clamp tightly to the end of the hose, making it a safe and reliable option for the connections of your brake system. If you need an efficient and safe brake system connection at a 45 degree angle, this stainless steel braided hose male thread 45 degree angle brake connector is just the right choice. Order now and make sure your brake system always works safely and efficiently.

This stainless steel braided hose male thread 90 degree angle brake coupler with sleeve is the ideal solution when the brake coupler needs to be turned at a 90 degree angle. It allows you to create an effective and safe connection to the brake system. This brake coupler's compression male thread ensures a perfect fit with steel braided hose, and its stainless steel construction ensures longevity. In addition, it is easy to install and clamp tightly to the end of the hose, making it a safe and reliable option for the connections of your brake system. The 90 degree angle allows the brake coupler to allow for steep angles in the brake system, which helps keep the system neat and compact. This will make your brake system more efficient and reduce the chance of damage to the hoses. If you need a safe and reliable brake connector at a 90 degree angle, this stainless steel braided male thread 90 degree angle brake connector is the best choice. Order a new Brake Hose now and make sure that your brake system always works safely and efficiently.

Chewing hose 0.7mm wall is a durable and transparent product, which is equipped with a metal spiral, which gives the hose additional strength and durability. Its wall thickness is 0.7 mm, and it offers good abrasion resistance and enables easy monitoring of liquid or air flow. Applications Chewing hose is designed for many different uses, including ventilation of industry, buildings and other premises and for transporting granular materials. It is also suitable as a hose for brush machines used in property maintenance, Industries Industry, construction, ventilation, cleaning. Benefits The chew hose offers excellent protection against fires and is highly resistant to oil and gasoline, making it useful for a wide variety of applications. Risks As a result of misuse or neglect of maintenance, the hose can become damaged or leak, emphasizing the importance of proper use and maintenance. Adapters The chewing hose is compatible with a wide variety of connectors, allowing it to be integrated into a wide variety of transfer systems. Chemical resistance The chew tube is designed to resist hydrolysis and microbes, making it a long-lasting choice. Operating temperatures The chewing hose has an operating temperature of -40 °C/+100 °C, so it is suitable for many different applications. Operating pressure classes The operating pressure class of the chewing hose is defined based on the use and explosion pressure class. Certificates and classes The chewing hose meets DIN 4102 B 1, ISO 8031 <109Ohm ja TRGS 727 <2,5108Ohm*m, ATEX 2014/34/EU ja DIN 26057 -standardit. Tutustu valikoimaamme ja pyydä tarjous jo tänään!

Here is a Chewing Hose with a 1.0mm wall, designed especially for industrial needs. It is the perfect solution for suction and blowing applications of consumables, offering a durable and versatile alternative. Applications The chewing hose is ideal for transporting lighter goods such as sawdust, dust and flour, as well as coarser material such as pellets, wood chips and grain. Industries Industry, construction, agriculture, wood processing. Property maintenance brush machines. Benefits This hose is very durable and long-lasting, maintaining its flexibility in varying temperatures (-40...+90 °C). Risks Improper use or maintenance can lead to damage to the hose and shorten its service life. Adapters The chew tube is compatible with several different connectors. Hoses Compatible with many different hoses. Chemical resistance The chewing hose is made to withstand various chemicals, offering reliability and longevity. Operating temperatures -40 - +90 Operating pressure classes 5 bar / 15 bar Certificates and classes DNV-GL, Bureau Veritas (BV), American Bureau of Shipping (ABS), EN 1474-II, EN 12434, EN 1474-III. We offer comprehensive advice on the selection of hoses, ensuring that you get a solution that suits your needs. Request a quote for Chewing Hose with 1.0mm wall today! Resistance

Chewing hose with a 0.6mm wall is a strong and durable choice for industrial needs. Its clear metal spiral reinforced construction makes it an ideal choice for transporting consumables and air. Applications Chemical industry, food industry, general industrial use. The transfer of grainy light materials and as an air conditioning hose. Industries Industry, chemical industry, food industry. Benefits The chew tube offers excellent resistance against wear and tear and its transparent structure allows you to follow the flow of liquid or air. Risks Improper use or maintenance can lead to hose damage and leaks. Chemical resistance The chewing hose is resistant to oil and gasoline, which increases its versatility. Operating temperatures -40 - +100 Operating pressure classes Information not available. Certificates and classes ISO 8031, TRGS 727, ATEX 2014/34/EU, BGI 739, DIN 26057. This chewing hose is designed to withstand the most demanding industrial conditions. Its reinforced structure and chemical resistance make it a reliable choice for a wide range of applications. Find out more and request an offer today!

Chewing hose 0.4mm wall is an industrial credit product that offers durability, reinforcement with a metal spiral and transparency for a wide range of needs. This hose is also suitable as an air conditioning hose and its operating temperature range is -40°C to +100°C. Applications Chemical industry, food industry, general industrial use. Destinations where consumables such as sawdust, glass, dust are moved Industries Chemical industry, food industry, general industrial use. Benefits Chew hose 0.4mm wall offers excellent wear resistance and meets fire safety standards, which makes it a safe and durable choice. Risks Misuse or poor maintenance can have harmful effects on the durability and functionality of the hose. Chemical resistance The chewing tube with a 0.4mm wall is designed to withstand hydrolysis and microbes, which guarantees its longevity. Operating temperatures Maintains its flexibility even at low temperatures. Operating pressure classes Chewing hose with a 0.4mm wall is designed to withstand the demanding pressure and suction conditions of industry. Certificates and classes ISO 8031, TRGS 727, ATEX 2014/34/EU, BGI 739, DIN 26057. This chewing hose is designed to meet the exact requirements of industry. Its reinforced structure and transparency make it a reliable choice for many applications. Contact us and request a quote today!

Composite hose PTFE 14 bar LBS with flanges is a top-class product for transferring industrial chemicals. The hose is made of durable red composite with LBS flanges and a PTFE Teflon membrane that provides excellent chemical resistance. Applications Chemical transfer in industrial environments, high-pressure chemical transfer applications. Industries Chemical industry, industrial production and processing. Benefits Composite hose PTFE 14 bar LBS with flanges is very flexible and light, so it is easy to handle and install. It is also a very durable and reliable solution for transferring chemicals. Risks Improper use or maintenance of the hose can lead to chemical leaks and damage the hose. That is why it is important to follow the operating and maintenance instructions. Adapters Compatible with many different hose fittings. Hoses Compatible with many different connectors. Chemical resistance The PTFE Teflon film offers excellent chemical resistance. Operating temperatures -30°C to +100°C Operating pressure classes 14 bar / 70 bar Certificates and classes The product meets industry quality and safety standards. If you need a reliable and durable solution for transferring chemicals, ask for a quote on Composite hose PTFE 14 bar LBS flanges.

Chemical hose EPDM 30bar is a high-quality hose designed for industrial and agricultural needs. It withstands up to 30 bar pressure, is very flexible and easy to handle. The outer surface is durable and wear-resistant, which makes it ideal for use with hot water, compressed air and coolants. Applications Industry, agriculture, hot water, compressed air, coolants. Industries Industry, agriculture, refrigeration. Benefits Chemical hose EPDM 30bar offers excellent durability and easy handling, which reduces the need for maintenance and replacement. Risks As a result of misuse or poor maintenance, the hose can become damaged, which emphasizes the importance of proper use and maintenance. Adapters Compatible with many industry standard connectors. Chemical resistance Made to withstand extreme chemical conditions, provides reliability and longevity. Certificates and classes EPDM hose meets strict industry standards and classifications. The composite hose for oil 10 bar is specially designed for oil transfer. It is durable and flexible, making it a versatile option for many industrial needs.

Air conditioning hose gray is an excellent choice for removing flue gases and steam in industrial environments. Its high-quality fiberglass construction and metal spiral reinforcement make it durable and long-lasting. Applications Removal of flue gases and steam, removal of air pollutants. Industries Industry, building, ventilation. Benefits The gray air conditioning hose is easy to install and its durable construction guarantees a long service life. Risks Improper installation or maintenance can lead to hose damage and ineffective operation. Adapters Compatible with many standard connectors. Chemical resistance The fiberglass construction and metal spiral reinforcement make the hose chemically resistant. Operating temperatures -40 - +120 Operating pressure classes 5 bar / 15 bar Certificates and classes NEN 6065/6066 1 3 DIN 4102 B2, DIN 4102 B2. Contact us to get a quote for Air conditioning hose, a gray, reliable and durable solution for removing flue gases and steam.

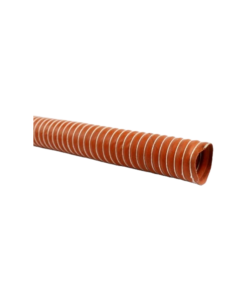

Air conditioning hoses -70°C-+250°C are single-wall, highly flexible and self-extinguishing hoses designed for demanding industrial applications. They withstand high internal and ambient temperatures and their outer wall is protected against ozone, weather, aging and seawater. These properties make the hoses ideal for use in challenging conditions where reliability and longevity are required. Applications Air conditioning systems, hot air blowers, industrial ovens, exhaust gas removal systems Industries Automotive industry, marine industry, chemical industry, aerospace industry Benefits High heat resistance and flexibility make it an excellent choice for demanding industrial applications. The hoses' long service life reduces maintenance costs and improves process efficiency. Risks Although the hoses are durable, using them in extreme conditions can shorten their lifespan. Incorrect installation can lead to malfunctions or damage. Adapters Not applicable Chemical resistance The hoses are highly resistant to ozone, weather effects and seawater, which makes them versatile for use in various industrial environments. Operating temperatures -35°C - +135°C Operating pressure classes Not specified Certificates and classes Not specified

Air conditioning hoses 135°c heavy are designed to withstand extreme conditions in demanding industrial applications. The hoses are double-walled and highly flexible, which ensures their longevity and efficiency. They are self-extinguishing and are excellently suited to high indoor and ambient temperatures. The outer wall materials are resistant to ozone, weather, aging and seawater. Applications Air conditioning systems, industrial ovens, hot air blowers, exhaust gas removal Industries Automotive industry, marine industry, chemical industry, energy production Benefits Air conditioning hoses 135°c heavy offer excellent heat and chemical resistance, which extends their service life and reduces maintenance costs. The flexible structure allows for easy installation and handling. Risks Although hoses are very durable, improper use or installation can reduce their performance. It is important to ensure that the hoses are the right type for the intended application. Adapters Compatible connectors: DIN standard hose connectors, SAE connectors Chemical resistance Air conditioning hoses are highly resistant to a wide range of chemicals, making them suitable for many industrial applications. Operating temperatures -35°C - +135°C Operating pressure classes 10 bar / 30 bar Certificates and classes ISO 9001, EN 45545-2, UL 94 V-0

Air conditioning hoses 135°c are designed for demanding industrial applications where a reliable and durable solution is required. The hose is single-walled, highly flexible and self-extinguishing, making it an ideal choice for high temperature environments. Its outer wall is resistant to ozone, weather, aging and seawater, ensuring a long service life. This air conditioning hose is the perfect partner for industrial professionals who demand the best performance and safety. Applications Air conditioning systems, industrial machines, heat exchangers, ventilation systems Industries Industry, marine and offshore industry, energy sector, construction industry Benefits Air conditioning hoses 135°c offer excellent flexibility and durability at high temperatures, reducing maintenance costs and improving system efficiency. Its self-extinguishing feature increases safety in demanding conditions. Risks Although the hose is very durable, its lifespan can be shortened if it is continuously exposed to extreme chemicals without proper maintenance. If installed incorrectly, the hose can pose a risk of leakage, which can lead to system malfunctions. Adapters Compatible connectors include standard air conditioning connectors and special connectors suitable for high temperatures. Chemical resistance Air conditioning hoses 135°c are highly resistant to ozone, weather effects and seawater, but are not designed for continuous exposure to strong chemicals. Operating temperatures -35 - +135°C Operating pressure classes 5 bar / 15 bar Certificates and classes No certifications or classes mentioned.

Teflon hose 5 bar is a durable and high-quality choice that offers reliability and longevity for industrial needs. The inner material of the hose is PTFE / Teflon and the outer material is PVC-coated polyester. The hose can withstand a pressure of 5 bar and its temperature range is -30 °C to +100 °C. Applications Teflon hose 5 bar is perfectly suited for use in petrochemicals, ports and ship to ship and ship to shore operations. Industries The hose is widely used in various industries, such as the petrochemical industry, ports and ships. Benefits Teflon hose 5 bar offers durability and reliability, which reduces maintenance and replacement needs. Risks Misuse or careless maintenance of the hose can lead to its damage. For this reason, it is important to observe proper use and maintenance. Adapters The Teflon hose 5 bar is compatible with various connectors, which allows it to be integrated into a wide range of systems. Chemical resistance Teflon hose 5 bar is made to withstand various chemicals, offering reliability and longevity. Certificates and classes The hose meets EN 13766: 2010, IMO, ICG codes. If you are looking for a durable and reliable hose for industrial needs, Teflon hose 5 bar is an excellent choice. Contact our experts and request a quote today!

Composite hose PTFE 14 bar is designed to withstand demanding industrial conditions. This high-quality hose with a PTFE inner membrane offers excellent pressure resistance and durability. The multi-layer construction ensures reliability and longevity, and it is compatible with a variety of standard connectors. This makes it an ideal choice for a variety of industries, such as the chemical and pharmaceutical industries and ports. Applications Chemical industry, food industry, pharmaceutical industry, oil and gas industry, offshore. Industries Chemical industry, food industry, pharmaceutical industry, oil and gas industry. Benefits Composite hose PTFE 14 bar offers excellent pressure resistance and longevity, making it a reliable choice for demanding conditions. The multi-layer construction ensures durability in various industrial applications. Risks An incorrectly installed or maintained hose can cause leaks and damage, so it is important to ensure proper installation and maintenance. Adapters Composite hose PTFE 14 bar is compatible with many standard connectors. Chemical resistance The PTFE inner membrane makes the hose highly resistant to various chemicals, such as acids and alkalis, as well as high temperatures. Certificates and classes Composite hose PTFE 14 bar meets industry standards: DNV, DNV PED, Bureau Veritas, Lloyd's Register of Shipping. Contact our experts and request a quote for this product.

Composite hose PTFE 10 bar is designed to withstand demanding industrial conditions. This red hose with a Teflon inner membrane offers excellent pressure resistance and durability. The multi-layer construction makes it a reliable choice for ports, ships and the chemical industry. Durability and reliability come together in this hose, which is compatible with a wide range of standard fittings. Applications Chemical industry, food industry, pharmaceutical industry, oil and gas industry, offshore. Industries Chemical industry, food industry, pharmaceutical industry, oil and gas industry. Benefits Composite hose PTFE 10 bar offers excellent pressure resistance and durability in demanding conditions. The multi-layer construction increases the hose's reliability and longevity. Risks An improperly used or maintained hose can cause damage and leaks, so proper use and maintenance is important. Adapters Composite hose PTFE 10 bar is compatible with several standard connectors. Chemical resistance The Teflon inner membrane makes the hose resistant to various chemicals, acids, bases and high temperatures. Certificates and classes Composite hose PTFE 10 bar meets industry standards: DNV, DNV PED, Bureu Veritas, Lloyds register of shipping. Contact our experts and request a quote for this product.