Hose clamp stainless The affordable clamp for coolant hose is a high-quality hose clamp made of AISI 304 stainless steel, which offers a reliable and durable solution for coolant hose assemblies. This clamp, which complies with the DIN 3017 standard, ensures safe and effective fastening with a 6 mm hexagon bolt. It is designed to withstand high pressures and temperatures, making it an ideal choice for engine coolant systems. Its ease of use and quick installation also make it a suitable choice for home use. Applications Machines, engines and equipment. Industries Boat manufacturing, vehicle industry, machinery and equipment maintenance. Benefits Durable and secure clamp provides reliable fastening in demanding conditions. Easy installation saves time and effort. Risks Tightening too much can damage the hose or the clamp. If installed incorrectly, the clamp will not achieve optimal tension. Chemical resistance Stainless AISI 304 material offers good protection against most chemicals, but is not suitable for all highly corrosive environments. Operating temperatures -40 - +120 Operating pressure classes 5 bar / 15 bar Certificates and classes DIN 3017 The clamp should be selected so that the size is as close as possible to the outer diameter of the hose, preferably the same. Size = Clamp clamping area.

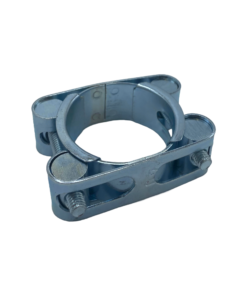

The PARI clamp AISI 316 is a durable and safe connection solution for industrial hoses. Its acid-resistant properties ensure reliable fastening in areas where there is a high risk of corrosion and rusting. With the help of two bolts, the clamp attaches evenly around the hose and stays firmly in place. Applications Pipelines, boats, ships, airplanes, fixing metal parts of buildings. Industries Industry, shipbuilding, aviation, construction industry. Benefits The PARI tensioner reduces the need for maintenance and extends the life of the equipment. Its use is safe and durable. Risks Improper installation or maintenance can lead to damage to the tensioner and thus equipment malfunctions. Chemical resistance Acid-resistant steel is resistant to various chemicals, which increases the life and safety of the product. Operating temperatures -40 - +120 Contact our experts, and we will help you find the perfect PARI tensioner for your needs.

The PARI hose clamp is an industrial credit product that offers a durable and safe connection method for industrial hoses. It is designed to withstand vibration, corrosion and moisture, making it extremely reliable. Applications Pipelines, boats, ships, fixing metal parts of buildings. Industries Industry, shipping, construction industry, mechanical engineering. Benefits The PARI hose clamp reduces the need for maintenance and extends the service life of the equipment, offering a reliable and safe connection method. Risks Improper installation or maintenance can result in tensioner damage and hose separation, so proper use and maintenance are important. Adapters The PARI hose clamp is compatible with many different hoses, offering a wide range of usage possibilities. Chemical resistance The PARI hose clamp is designed to withstand chemical stresses, offering a long-lasting solution for industrial needs. Operating temperatures -40 - +120 If you need help choosing the right tensioner, feel free to contact us. We help you find the best solution for your needs.

The hose clamp for rubber and plastic hoses is designed to provide a reliable and durable solution for industrial needs. This high-quality hose clamp ensures a secure hold for both rubber and plastic hoses, reducing hose movement and wear. The easy-to-use and convenient-to-install hose clamp is suitable for a wide range of industrial environments. Its compact design allows for flexible use in a variety of applications. Applications Rubber and plastic hoses, industrial equipment, machinery Industries Industry, machine shops, production plants Benefits The hose clamp provides a stable and secure attachment, which extends the life of the hoses and reduces maintenance costs. Risks If installed incorrectly, a hose clamp can cause hose damage or leaks, so careful installation is important. Hose clamps that are the wrong size can also weaken the connection and increase the risk of breakage. Hoses Suitable for commonly used rubber and plastic hoses Chemical resistance The hose clamp is made of materials that are resistant to most chemicals used in industry. Operating temperatures -20 - +80 Operating pressure classes 5 bar / 15 bar Certificates and classes ISO 9001, CE marked

The hose clamp for rubber and plastic hoses is designed to provide a reliable and durable solution for industrial needs. This high-quality hose clamp ensures a secure hold for both rubber and plastic hoses, reducing hose movement and wear. The easy-to-use and convenient-to-install hose clamp is suitable for a wide range of industrial environments. Its compact design allows for flexible use in a variety of applications. Applications Rubber and plastic hoses, industrial equipment, machinery Industries Industry, machine shops, production plants Benefits The hose clamp provides a stable and secure attachment, which extends the life of the hoses and reduces maintenance costs. Risks If installed incorrectly, a hose clamp can cause hose damage or leaks, so careful installation is important. Hose clamps that are the wrong size can also weaken the connection and increase the risk of breakage. Hoses Suitable for commonly used rubber and plastic hoses Chemical resistance The hose clamp is made of materials that are resistant to most chemicals used in industry. Operating temperatures -20 - +80 Operating pressure classes 5 bar / 15 bar Certificates and classes ISO 9001, CE marked

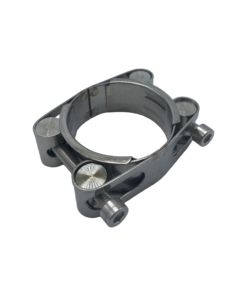

Chewing hose clip is a very durable and reliable solution for industrial needs for chewing hoses of different sizes. It is designed to withstand demanding conditions and provide a long-lasting, safe and effective solution for chewing hose connections. Applications The chewing hose clip is perfectly suited for use in industry, construction sites and other demanding environments. Industries Industry, construction, equipment manufacturers, plastic manufacturing, maintenance and repair services. Benefits The chewing hose clamp offers maximum performance and durability, reducing the need for maintenance and replacement. Risks Improper use or maintenance can lead to damage to the clamp and, as a result, hose leaks. Correct use and regular maintenance are essential to guarantee the longevity of the product. Adapters The chew tube clip is compatible with several different crimped chew tubes, offering flexibility and versatility. Chemical resistance The chewing tube clip is made of high-quality materials that are resistant to various chemicals, offering a long-lasting and reliable solution. Operating temperatures -40 - +120 Ask for a quote for the Chewing hose clamp and make sure that you have a durable and reliable solution for the purchase and replacement of hoses.

Chewing hose clip is a very durable and reliable solution for industrial needs for chewing hoses of different sizes. It is designed to withstand demanding conditions and provide a long-lasting, safe and effective solution for chewing hose connections. Applications The chewing hose clip is perfectly suited for use in industry, construction sites and other demanding environments. Industries Industry, construction, equipment manufacturers, plastic manufacturing, maintenance and repair services. Benefits The chewing hose clamp offers maximum performance and durability, reducing the need for maintenance and replacement. Risks Improper use or maintenance can lead to damage to the clamp and, as a result, hose leaks. Correct use and regular maintenance are essential to guarantee the longevity of the product. Adapters The chew tube clip is compatible with several different crimped chew tubes, offering flexibility and versatility. Chemical resistance The chewing tube clip is made of high-quality materials that are resistant to various chemicals, offering a long-lasting and reliable solution. Operating temperatures -40 - +120 Ask for a quote for the Chewing hose clamp and make sure that you have a durable and reliable solution for the purchase and replacement of hoses.

Transparent heat shrink tubing with adhesive is designed to provide excellent protection and insulation for demanding industrial applications. This strong and clear heat shrink tubing allows for easy inspection and monitoring, as its transparent construction makes the contents visible. The adhesive-coated inner surface ensures a tight and durable seal that prevents moisture and contaminants from penetrating. Heat shrink tubing is the ideal solution when reliable protection and insulation is required in a variety of industrial applications. Applications Electrical installations, cable protection, hose connection insulation, joint sealing Industries Electronics industry, automotive industry, aerospace industry, engineering industry Benefits Heat shrink tubing with adhesive provides excellent protection and durability, extending the life of cables and connections. Transparent construction allows for easy visual inspection after installation. Shrinkage ratio 3:1. Risks Incorrect installation of heat shrink tubing can reduce its tightness and protective properties. Excessively high temperatures may affect the performance of heat shrink tubing. Chemical resistance Heat shrink tubing is highly resistant to many industrial chemicals, but strong solvents can degrade its properties. Operating temperatures -40 to +125°C Operating pressure classes Not suitable for applications requiring pressure resistance

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. In summary, it can be stated that choosing the right stem seal is crucial for the operation of the hydraulic system. A high-quality stem seal helps to avoid unnecessary maintenance costs, increases the service life of the system and improves the safety of the system. This applies to all stem sizes, such as a 120mm stem seal.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using a 95mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using an 85mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using a 100mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

The importance of the 90mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit the 90mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 70mm stem seal, you can avoid unnecessary maintenance costs and extend the life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 90mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 80mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 80mm stem seal, you can avoid unnecessary maintenance costs and extend the service life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 80mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 70mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 70mm stem seal, you can avoid unnecessary maintenance costs and extend the life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 70mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 65mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 65mm stem seal, you can avoid unnecessary maintenance costs and extend the service life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 65mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

A high-quality cylinder head gasket is a vital part of the hydraulic system, whose role is to prevent oil leakage and ensure efficient operation of the system. Our range includes high quality 63mm stem seals made from durable materials such as rubber, PTFE or PU. The design and size of the seals are precisely designed to fit the 63mm stem, so that they fit perfectly into the system used by the customer. Our seals are very durable and have a long service life. They can be used in many types of hydraulic systems where a seal is needed for a 63mm stem. The use of a high-quality seal reduces unnecessary maintenance costs and ensures the efficient operation of the system. In addition, the use of a high-quality seal improves the safety of the system, as it reduces the risk of oil leaks, which can cause dangerous situations in e.g. lifting equipment. Our range of 63mm stem seals are top quality and affordable. They are made of durable materials, so they last even in heavy use. By choosing a high-quality cylinder stem seal from us, you can be sure of the safety and efficiency of your system.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. It is important to note that gaskets designed for different sized stems are not interchangeable. For example, a 60mm stem seal is not suitable for a 40mm stem, as its dimensions and sealing ability are designed differently. That is why it is important to choose the right size and suitable seal for the size of the stem and the oil used. With the help of a high-quality stem seal, problems caused by oil leaks can be avoided, which can affect the operation and safety of the system. In summary, it can be stated that choosing the right stem seal is crucial for the operation of the hydraulic system. A high-quality stem seal helps to avoid unnecessary maintenance costs, increases the service life of the system and improves the safety of the system.

The hydraulic system consists of many different parts, one of the most central of which is the stem seal of the hydraulic cylinder. The stem seal is a necessary part of the system, as its job is to prevent oil leakage and ensure that the system works efficiently. Durable materials such as rubber, PTFE or PU are used as manufacturing materials, and the design and size of the stem seal are precisely designed to fit a 40mm stem. Choosing the right stem seal is crucial for the system to function safely and efficiently. With the help of a high-quality stem seal, unnecessary maintenance costs can be avoided and the service life of the system can be extended.

The hydraulic system consists of several different parts, and one of them is the stem seal of the hydraulic cylinder. The stem seal is an important part of the system, as its task is to prevent oil leakage and ensure the efficient operation of the system. Stem seals are made from durable materials, such as rubber, PTFE or PU, and the shape and size of the seal are precisely designed to fit a 40mm stem. Choosing the right stem seal is particularly important for the system to function safely and efficiently. A high-quality stem seal helps to avoid unnecessary maintenance costs and extends the service life of the system. In a search engine-friendly way, you can emphasize, for example, the importance of a high-quality stem seal for the safety and efficiency of the system.