The unreinforced flexible silicone hose is flexible and almost transparent, making it an excellent choice for non-pressurized applications. Its incredible flexibility and high chemical resistance make it a versatile and reliable choice for different situations. Applications Non-pressurized applications, visual monitoring for flow and possible blockages. Industries Industry, food and pharmaceutical industry. Benefits Silicone hose's incredible flexibility and high chemical resistance make it a versatile and reliable choice. Risks Improper use or maintenance can lead to hose damage and leaks. Chemical resistance The silicone hose is made to withstand chemicals and other aggressive substances. Operating temperatures -60°C/+180°C Certificates and classes FDA 21 CFR 177.2600 Non-reinforced flexible silicone hose is a reliable and durable choice for non-pressurized applications. Its incredible flexibility and high chemical resistance make it a versatile and reliable choice for different situations. Request a quote today!

The ultra-light output connector is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made of high-quality materials, ensuring its lightness and easy handling without compromising on durability. The ultra-light output connector is ideal for versatile installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-light output connector offers quick installation and low maintenance, which reduces operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-light output connector is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The ultra-light output connector is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made of high-quality materials, ensuring its lightness and easy handling without compromising on durability. The ultra-light output connector is ideal for versatile installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-light output connector offers quick installation and low maintenance, which reduces operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-light output connector is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The ultra-light nut is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made from high-quality materials, ensuring its lightness and ease of handling without compromising on durability. The ultra-light nut is ideal for a variety of installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-lightweight nut offers quick installation and low maintenance, reducing operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-lightweight nut is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

The ultra-light extension connector is designed to provide optimal performance and durability in demanding industrial environments. This innovative connector is made of high-quality materials, ensuring its lightness and easy handling without compromising on durability. The ultra-light extension connector is ideal for versatile installations where precision and reliability are required. Its compact design allows for quick installation and reduces downtime in production processes. applications Industrial piping, compressed air systems, hydraulic systems, process industry equipment industries Chemical industry, oil and gas industry, food industry, pharmaceutical industry benefits The ultra-light extension connector offers quick installation and low maintenance, which reduces operating and maintenance costs. It increases system reliability and extends service life. the risks If installed incorrectly, the connector may cause leaks, which can lead to serious system damage. Service personnel must be aware of the installation instructions and follow them carefully. tubing Compatible connectors include BSP, NPT and JIC connectors. chemical resistance The ultra-light extension connector is highly resistant to a wide range of chemicals, making it an ideal choice for demanding industrial environments. operating temperatures -40 - +200°C operating pressure classes 10bar / 300bar

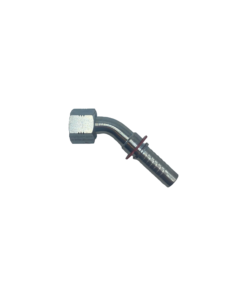

Hydraulics systems ORFS 90 degree elbow hose connector with internal thread. Steel and sturdy connector for all hydraulic hose assemblies. These connectors have a UN thread level with sealing. This connector requires a 90 Shore o-ring all the way to the outer thread of the connector. The o-ring in question should be replaced every time the connector needs to be replaced. Due to its structure, the connector is easy to thread. This nipple is available in many different sizes. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. The thread table of orfs connectors below shows the exact thread of the un connector.

ORFS hose connector for hydraulic systems with internal thread. Steel and sturdy connector for all hydraulic hose assemblies. These connectors have a UN thread level with sealing. This connector requires a 90 Shore o-ring all the way to the outer thread of the connector. The o-ring in question should be replaced every time the connector needs to be replaced. Due to its structure, the connector is easy to thread. This nipple is available in many different sizes. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. The thread table of orfs connectors below shows the exact thread of the un connector.

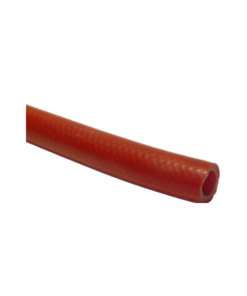

Silicone hose fabric reinforcement red is designed for industrial professionals who need a durable and reliable hose. This hose is particularly popular in the food industry, its red color stands out clearly and makes detection easier, thus improving safety and usability. Applications Food and beverage industry, chemical industry, temperature regulation. Industries Food industry, chemical industry, temperature control. Benefits The silicone hose fabric reinforcement red is very durable and easy to clean, thanks to which it meets the high hygiene requirements of the food industry. Risks Due to misuse or neglect of maintenance, the hose may be damaged, in which case its operation is no longer optimal. Chemical resistance This hose is designed to withstand high temperatures and chemicals, making it a very reliable choice. Operating temperatures -60°C/+140°C. Operating pressure classes This hose can withstand pressure and suction, making it very durable. Certificates and classes FDA 21 CFR 177.2600. Want to know more? Contact us and request a quote for the Silicone hose fabric reinforcement red product today!

Silicone hose with a steel spiral is a food-grade, extremely flexible and durable product designed especially for the needs of the food industry. Its chemical resistance and high temperature resistance make it a reliable choice for many applications. Applications Food industry, high temperature applications, chemical exposure. Industries Food industry, chemical industry, heat treatment. Benefits Silicone hose steel spiral is a long-lasting and durable product that offers reliable performance over a long period of time. Risks As a result of misuse or neglect of maintenance, the hoses can be damaged or react with food. Adapters The silicone hose steel spiral is compatible with several standard fittings, allowing it to be used in a wide range of applications. Chemical resistance The silicone hose steel spiral is chemical resistant, which means it will not break down or react with food. Operating temperatures -60 °C to +200 °C Operating pressure classes 5 bar / 15 bar Certificates and classes FDA 21 CFR 177.2600, Ey 1935/2004, 3A sanitary standard class II, 1907/2006/CE REACH Request a quote for silicone hose with steel spiral and you will be sure to get a solution that fits your needs.

Silicone hose without reinforcement is a high-quality and flexible product that offers excellent resistance at high temperatures. This tubing is highly chemical resistant and easy to clean and sterilize. Its versatility and longevity make it an excellent choice for many industries. Applications Medical devices, food industry, various industrial applications. Industries Medicine, food industry, industrial sector. Benefits Silicone hose without reinforcement offers excellent durability and flexibility, which makes it a reliable choice for many applications. Risks Improper use or maintenance can lead to hose damage. It is important to follow the correct operating and maintenance instructions. Chemical resistance Silicone hose is highly resistant to chemicals, which makes it a reliable choice for many different applications. Operating temperatures -60°C to +200°C Certificates and classes FDA 21 CFR 177.2600, EC 1935/2004, 3A sanitary standard class II, 1907/2006/CE REACH Contact our experts for more information and to request an offer for the Silicone hose without reinforcement product.

The properties of silicone hoses are said to be very flexible and durable, withstanding high temperatures. Silicone hoses are ideal for medical devices and the food industry because they are chemical resistant and easy to clean and sterilize. In addition, silicone hoses have good flexibility, which allows them to be used in many applications. They are also long-lasting and extremely durable, making them suitable for a wide range of applications. The practicality and reliability of silicone hoses make them an excellent choice for many industries. Thanks to its special construction, this hose is suitable for higher working pressures than the standard version. Contact us in the chat and we will help you choose the right hose. Inner wall: silicone Outer wall Ozone and UV resistant, High temperature resistant, Odorless and tasteless. Type reinforcements Highest temperature resistant reinforcements, Steel spiral Temperature range °C -60°C/+200°C Standard FDA 21 CFR 177.2600, EC 1935/2004, 3A sanitary standard class II, 1907/2006/CE REACH

Silicone hose with reinforcement blue is a very flexible and durable product, which is excellently suitable for use in industry and various machines and devices. It can withstand high temperatures and is an excellent choice especially for low-pressure cooling water systems of engines. Applications Industry, machinery and equipment, low-pressure cooling water systems for engines. Industries Industry, motor industry, machine and equipment industry. Benefits Silicone hose with blue reinforcement is very flexible and durable, which guarantees its longevity and reliability. Risks Improper use or maintenance can lead to hose damage, so proper use and maintenance is important. Chemical resistance The blue reinforced silicone hose is excellently resistant to cooling water containing glycol and is easy to clean and sterilize. Operating temperatures Withstands high temperatures. Operating pressure classes Perfect for low-pressure cooling water systems. We are happy to help you choose the right silicone hose. Contact us in the chat to get a quote for this product.

The threaded reducing fitting is a versatile and durable solution for industrial applications where a reduced thread is required. Made from high-quality brass, this fitting is ideal for handling compressed air, water and fuels. Its design allows for easy installation and reliable use in demanding conditions. This makes it an ideal choice for industrial professionals looking for an efficient and long-lasting fitting. Applications Compressed air, water, fuels Industries Industry, marine industry, engineering industry Benefits The threaded reduction fitting offers a reliable seal and a durable construction that reduces maintenance requirements. It is designed for long service life. Risks If installed incorrectly, the connector can cause leaks or pressure loss. It is important to ensure that the connector is installed correctly and is suitable for the application being used. Hoses Compatible with various compressed air and fuel hoses Chemical resistance The brass construction offers good resistance to many chemicals, but it is recommended to check compatibility individually. Operating temperatures -20 - +120°C Operating pressure classes 10bar / 25bar Certificates and classes No certificates mentioned

The threaded coupling is a premium low-pressure coupling with inch threads, designed specifically for industrial applications. Its durable material makes it an excellent choice for handling compressed air, fuels and water. This versatile coupling provides a reliable connection that can withstand even the most demanding conditions. The threaded coupling is easy to install and guarantees long-lasting performance. Applications Compressed air, fuels, water Industries Industry, engineering workshops, energy industry Benefits The threaded coupling provides a reliable connection and durable performance in a variety of industrial applications. It is easy to install and requires little maintenance. Risks If installed incorrectly, a threaded sleeve can cause leaks and reduce the functionality of the system. It is important to ensure proper installation and regular inspection. Hoses Compatible with most standard threaded hoses Chemical resistance The threaded sleeve is highly resistant to most common industrial chemicals, making it a versatile solution. Operating temperatures -20 - +80°C Operating pressure classes 6bar / 18bar Certificates and classes No specific certifications or classes mentioned

The 90 degree grease nipple is designed to facilitate access to lubrication points, especially in tight and difficult-to-reach areas. This angled grease nipple allows for smooth lubrication without the need to disassemble other components. Made of durable material, it ensures longevity and reliability even in demanding conditions. Compatible with a variety of connector types, it offers a versatile solution for industrial needs. Applications Machine shops, automotive industry, agricultural machinery, construction machinery, marine industry Industries Industry, logistics, maintenance, production, construction Benefits The 90* grease nipple enables easy and efficient lubrication in tight spaces, improving equipment life and reducing maintenance costs. Its durable design ensures reliable performance in a variety of industries. Risks If installed incorrectly, a grease nipple can cause lubricant leakage, which can lead to premature wear of the equipment. In addition, incompatible fittings can impair the function of the nipple and cause damage.

The 45 degree grease nipple is specially designed for industrial applications where reliable and efficient lubrication is required in hard to reach areas. This angled nipple allows for easy installation and lubrication even in tight spaces, improving the performance and service life of machines and equipment. Made of durable material, it ensures long life and reliable operation. The grease nipple is ideal for a wide range of industrial applications where precise and efficient lubrication is required. Applications Machines, equipment, vehicles, industrial equipment, hard-to-reach lubrication points Industries Mechanical industry, automotive industry, manufacturing industry, heavy industry Benefits The grease nipple with a 45-degree angle provides easy installation and lubrication in tight spaces, improving equipment performance and reducing maintenance costs. Risks Incorrect installation can lead to a lack of lubrication and premature wear of the equipment. In addition, the use of the wrong type of lubricant can negatively affect the durability of the product.

A grease nipple is an essential component that ensures efficient lubrication in industrial machinery. This straight grease nipple is equipped with an external thread, which makes it easy to connect it to various equipment. Its durable construction ensures reliable performance in demanding operating conditions. Designed specifically for industrial needs, this grease nipple is an ideal choice for maintenance needs. Applications Machine lubrication systems, hydraulic systems, industrial equipment, heavy equipment maintenance Industries Manufacturing industry, transportation, construction, agriculture Benefits The grease nipple ensures efficient lubrication, which extends the life of the equipment and reduces maintenance costs. Risks An incorrectly installed grease nipple can lead to leaks and loss of power, which may cause damage to the equipment. Hoses Compatible connectors: BSP threads, NPT threads Chemical resistance The grease nipple is designed to withstand most lubricants used in industry.

The threaded coupling is a premium low-pressure coupling with inch threads, designed specifically for industrial applications. Its durable material makes it an excellent choice for handling compressed air, fuels and water. This versatile coupling provides a reliable connection that can withstand even the most demanding conditions. The threaded coupling is easy to install and guarantees long-lasting performance. Applications Compressed air, fuels, water Industries Industry, engineering workshops, energy industry Benefits The threaded coupling provides a reliable connection and durable performance in a variety of industrial applications. It is easy to install and requires little maintenance. Risks If installed incorrectly, a threaded sleeve can cause leaks and reduce the functionality of the system. It is important to ensure proper installation and regular inspection. Hoses Compatible with most standard threaded hoses Chemical resistance The threaded sleeve is highly resistant to most common industrial chemicals, making it a versatile solution. Operating temperatures -20 - +80°C Operating pressure classes 6bar / 18bar Certificates and classes No specific certifications or classes mentioned

The crowbar is specially designed for the nut driver, providing an efficient and reliable tool for industrial professionals. This product is made of high-quality materials that ensure long service life and durability in demanding conditions. Its ergonomic design allows for easy and safe use, reducing fatigue and improving work efficiency. The crowbar is the ideal solution when precise and powerful torque is required. Applications Industrial plants, maintenance and repair work, assembly lines, heavy machinery Industries Automotive industry, engineering industry, construction industry, marine industry Benefits The crowbar offers excellent torque, which improves work efficiency and reduces work time. Its durable construction ensures longevity and reliability in demanding applications.