Deep groove ball bearing 6200 series c3 is designed to withstand even the most demanding industrial conditions. This bearing is part of the high-quality FAG 6200 series and has a C3 clearance, making it an excellent choice for heavy duty applications and high loads. Its design ensures reliable performance and a long service life, reducing maintenance requirements and improving the efficiency of production processes. Its compact size makes it easy to install in a variety of applications. Applications Motors, pump shafts, conveyor systems, industrial machinery Industries Automotive industry, mechanical engineering, food industry, paper industry Benefits Deep groove ball bearing 6200 series c3 offers excellent durability and reliability, which improves machine life and reduces downtime. Risks If installed incorrectly, bearing performance may be compromised, leading to increased wear and failure.

Deep groove ball bearing 6200 series c3 is designed to withstand even the most demanding industrial conditions. This bearing is part of the high-quality FAG 6200 series and has a C3 clearance, making it an excellent choice for heavy duty applications and high loads. Its design ensures reliable performance and a long service life, reducing maintenance requirements and improving the efficiency of production processes. Its compact size makes it easy to install in a variety of applications. Applications Motors, pump shafts, conveyor systems, industrial machinery Industries Automotive industry, mechanical engineering, food industry, paper industry Benefits Deep groove ball bearing 6200 series c3 offers excellent durability and reliability, which improves machine life and reduces downtime. Risks If installed incorrectly, bearing performance may be compromised, leading to increased wear and failure.

Bearing 7200 series angular contact ball bearings are designed to withstand high loads and provide long-lasting performance in demanding industrial applications. The bearings in the series ensure smooth and quiet operation, thanks to precisely manufactured components. High-quality materials ensure wear resistance and the ability to withstand temperature fluctuations. They are ideal choices for various industrial needs where reliability and efficiency are required. Applications Machine shops, conveyor lines, hydraulic systems, production plants Industries Mechanical industry, electronics industry, automotive industry, energy industry Benefits 7200 series bearings offer excellent durability and reduce maintenance requirements, resulting in lower operating costs and longer service life. Risks Incorrect installation or neglect of maintenance can lead to premature wear and possible bearing damage, highlighting the importance of professional maintenance.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.

Deep groove ball bearing 6300 series 2rs is designed to withstand heavy use in demanding industrial applications. This top quality bearing is plastic protected, ensuring excellent durability and longevity. Its robust construction makes it an ideal choice for applications where reliability and performance are required. Perfectly suited for industrial needs where quality and durability are primary requirements. Applications Mechanical engineering, transportation systems, industrial robots, electric motors Industries Industry, logistics, automation, energy Benefits The 6300 series 2rs deep groove ball bearing offers excellent durability and reliability in demanding conditions. Its plastic-protected design reduces maintenance and extends service life. Risks Using a bearing without proper maintenance can shorten its service life. Improper installation can lead to premature wear.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.

Deep groove ball bearing 6000 series C3 is designed to meet the demands of industry with durability and reliability. This metal-shielded bearing offers excellent performance and low maintenance requirements, making it an ideal choice for demanding operating conditions. Its robust construction ensures long life and efficient bearing performance. The optimal choice when reliable bearing performance is required in industrial environments. Applications Machinery, conveyor equipment, industrial production lines, electric motors Industries Automotive industry, food industry, metal industry, construction industry Benefits Deep groove ball bearing 6000 series C3 offers excellent wear resistance and reduces downtime. Its metal protection effectively protects against dust and dirt. Risks If installed incorrectly, the bearing can cause excess friction and wear. Failure to maintain it can lead to premature failure.

Deep groove ball bearing 6300 series C3 is designed to withstand demanding industrial conditions. This premium bearing is plastic-encased, providing excellent protection against dust and moisture. The bearing's C3 clearance allows for improved performance at high temperatures and speeds. It is the ideal solution when reliability and longevity are required. Applications Electric motors, conveyor systems, pumps, industrial gearboxes Industries Automotive industry, food industry, paper industry, engineering industry Benefits Deep groove ball bearing 6300 series C3 offers excellent durability and low maintenance requirements, improving machine reliability and reducing downtime. Risks If installed incorrectly, the bearing's performance may be reduced, which can lead to premature wear. Poor operating conditions, such as excessive moisture or dirt, can shorten the bearing's service life. Chemical resistance Thanks to the plastic protection, the bearing is resistant to most industrial chemicals, but it can be damaged by highly corrosive substances.

Deep groove ball bearing 6300 series 2rs is designed to withstand heavy use in demanding industrial applications. This top quality bearing is plastic protected, ensuring excellent durability and longevity. Its robust construction makes it an ideal choice for applications where reliability and performance are required. Perfectly suited for industrial needs where quality and durability are primary requirements. Applications Mechanical engineering, transportation systems, industrial robots, electric motors Industries Industry, logistics, automation, energy Benefits The 6300 series 2rs deep groove ball bearing offers excellent durability and reliability in demanding conditions. Its plastic-protected design reduces maintenance and extends service life. Risks Using a bearing without proper maintenance can shorten its service life. Improper installation can lead to premature wear.

Deep groove ball bearing 16000 series is designed to meet the exacting requirements of industry, providing a reliable and durable solution for a wide range of applications. These high-quality bearings guarantee long-lasting performance and low friction, making them ideal for demanding environments. Deep groove ball bearing 16000 series is known for its excellent load capacity and seamless operation. Its innovative design ensures easy installation and maintenance-free operation. Applications Machines, conveyor lines, electric motors, pumps Industries Industry, manufacturing, energy, transportation Benefits The 16000 series deep groove ball bearing offers excellent load and wear resistance, which extends equipment life and reduces maintenance needs. Risks An incorrectly selected bearing can lead to increased friction and wear, which can shorten the life of the equipment and cause downtime.

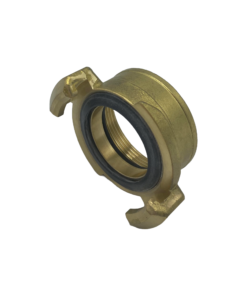

The brass fire connector is a high-quality connector specially designed for the diverse needs of industry. Its lightweight yet durable construction makes it an ideal choice for submersible pump use and other demanding applications. Equipped with an external thread and sealing ring, it ensures a reliable connection and longevity in various hose systems. Available with different claw spacing sizes, allowing for precise and safe installation. Applications Industrial plants, fire hydrants, submersible pumps, hose systems Industries Firefighting, industry, construction, water supply Benefits The fire hose connector offers a combination of lightness and durability, which facilitates installation and extends the product's service life. It ensures a reliable connection and reduces the risk of leaks. Risks An incorrectly selected connector size can cause leaks and an unreliable connection, which can lead to damage and downtime. It is important to check the gap carefully before installation. Hoses Compatible with fire hydrant hoses, submersible pump hoses and other industrial hoses Chemical resistance The hose connector of the fire connector is resistant to many chemicals used in industry, but it is recommended to check compatibility before use. Operating temperatures -20 to +80°C Operating pressure classes 10bar / 16bar Certificates and classes Made in Finland

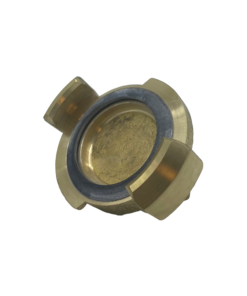

The Fire Connector Internal Thread Brass is a high-quality connector designed to withstand demanding conditions. Made of aluminum, it is lightweight yet durable, making it an excellent choice for a variety of water and fire hydrant applications. Its internal thread and sealing ring ensure a reliable connection and easy installation. Careful measurement of the claw gap ensures optimal operation. Applications Fire hydrants, submersible pumps, water lines, pumps. Suitable for suction and pressure. Industries Industry, construction, municipal engineering Benefits The internal thread of the fire connector is lightweight and durable, making it easy to handle and install. It provides a reliable connection that can withstand even the most demanding operating conditions. Risks Choosing the wrong nail spacing can lead to loosening or leakage of the joint. Careful sizing and choosing the right size are essential to ensure safe use. Hoses Compatible connectors include standard-sized fire connectors and water line connectors. Chemical resistance The aluminum construction offers good corrosion resistance, but is not suitable for strongly acidic or alkaline environments. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar

The brass conversion fire connector is designed to facilitate the efficient connection of hoses of different sizes. This durable and reliable connector reduces installation time and improves work flow. If necessary, our experts can manufacture customized conversions for different connectors. Remember to check the claw spacing to ensure the correct size. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with a variety of industrial hoses, including 2", 3" and 4" connectors. Chemical resistance The brass construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The Palolitt diverter valve is designed for efficient and reliable hose branching in industrial applications. Made of high-quality Finnish aluminum, it combines the advantages of gate valves and ball valves. This diverter offers a durable solution that allows two hose lines to be connected to a main line. Available in two different models, it meets a variety of industrial needs. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with many industrial hoses and fire fittings. Chemical resistance The aluminum construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The aluminum fire connector conversion is designed to make it easier to fit connections between different sizes of hoses. This durable and reliable connector allows you to effectively reduce the connection size, which reduces installation time and improves workflow. If necessary, our experts can manufacture customized conversions for different connectors. Remember to check the claw spacing to ensure the correct size. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with a variety of industrial hoses, including 2", 3" and 4" connectors. Chemical resistance The aluminum construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The brass fire connector plug is designed to provide a reliable and durable solution for demanding industrial needs. Its lightweight and durable construction makes it an ideal choice for submersible pumps, water lines and other industrial systems. The sealing ring ensures a tight connection, making it an excellent choice for critical systems. This product is widely used in Finnish fire hydrants, which highlights its suitability for fire safety. Applications Submersible pumps, water lines, fire hydrants, industrial systems Industries Industry, municipal engineering, fire safety Benefits The brass fire connector plug offers a lightweight yet durable solution for industrial needs, ensuring a tight and reliable connection. Its aluminum construction allows for easy handling and installation. Risks Selecting the wrong size can lead to leakage or unreliable connections. It is important to ensure the correct gap and compatibility of the connector with the application. Chemical resistance The aluminum construction is highly resistant to most chemicals used in industry, but it is recommended to check specific chemical cases before use. Operating temperatures -20 to +80°C Operating pressure classes 5bar / 16bar

The aluminum hose connector is designed to provide a reliable and durable solution for industrial needs. Made from high-quality aluminum, it combines lightness with excellent durability. The connector design allows for easy installation and ensures a tight connection. It is the ideal choice when you are looking for a long-lasting and efficient connector for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The aluminum hose connector provides a lightweight yet durable connection that can withstand harsh industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector can cause leaks or impair the function of the hose system. It is important to ensure that the connector is compatible with the hose being used. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The aluminum hose connector is designed to withstand a variety of industrial chemicals, but is not recommended for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar

Brass hose connector female thread is designed to meet the demanding industry standards. Made from high quality brass, this connector offers excellent durability and performance. Easy installation and a tight connection ensure reliable operation in a wide range of applications. The brass construction makes it a long-lasting and efficient solution for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The brass hose connector provides a durable connection that performs reliably in demanding industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector may cause leaks or impair system performance. Compatibility with the hose being used must be ensured. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The brass hose connector is resistant to many industrial chemicals, but is not suitable for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar Certificates and classes Fire connector used in Finland

The aluminum hose connector with internal thread is designed to meet the demanding needs of industry. Made from high-quality aluminum, this connector combines lightness and durability, making it an ideal choice for many applications. Easy installation and a tight connection ensure reliable operation. This connector is a long-lasting and efficient solution that is ideal for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The aluminum hose connector provides a lightweight yet durable connection that can withstand harsh industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector can cause leaks or impair the function of the hose system. It is important to ensure that the connector is compatible with the hose being used. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The aluminum hose connector is designed to withstand a variety of industrial chemicals, but is not recommended for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar