Deep groove ball bearing 6300 series 2ZR is a high-quality bearing equipped with a durable metal shield. This bearing offers reliability and long service life in various industrial applications. It is designed to withstand demanding conditions and effectively reduce friction. The metal shield protects the bearing from dust and other contaminants, making it an excellent choice for demanding environments. Applications Industrial equipment, conveyor belts, electric motors, pumps Industries Automotive, manufacturing, energy, engineering Benefits Deep groove ball bearing 6300 series 2ZR offers excellent durability and performance, reducing the need for maintenance and improving equipment reliability. Risks Although the bearing is protected by a metal shield, its service life may be shortened if it is continuously exposed to extreme temperatures or humidity.

Bearing 6000 series 2rs is a high-quality deep groove ball bearing, especially suitable for demanding industrial environments. Its plastic-protected structure protects against dust and moisture, which extends the bearing's service life and ensures reliable operation. The bearing is available in several different size options, allowing it to be used in a wide range of applications. Easy installation and maintenance make it a popular choice for professionals. Applications Industrial machinery, conveyor systems, electric motors, pumps Industries Manufacturing industry, energy sector, logistics, mechanical engineering Benefits The 6000-2rs bearing offers excellent wear resistance and reduced maintenance. Its plastic-protected design ensures reliable operation in challenging conditions. Risks If installed incorrectly, the service life of the bearing can be significantly reduced. Poor lubrication can also lead to premature wear.

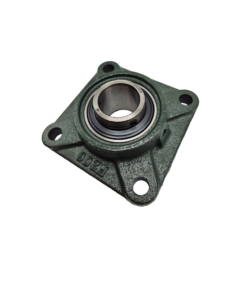

The UCF bearing unit is a cast iron flange bearing unit containing a UC bearing. This durable unit is secured to the base with two bolts and the bearing has retaining screws to ensure stability. Designed specifically for industrial applications, the UCF bearing unit provides a reliable and long-lasting solution for a wide range of applications. Its easy installation and maintenance-free design make it an excellent choice for demanding environments. Applications Conveyor systems, production lines, industrial machinery, agricultural equipment Industries Industry, logistics, agriculture, mechanical engineering Benefits The UCF bearing unit offers excellent durability and low maintenance requirements, making it a cost-effective solution for long-term use. Risks If installed incorrectly, the bearing unit may cause malfunctions or shorten its service life. Regular inspection is recommended to detect any potential problems in time. Chemical resistance The cast iron construction offers good resistance to most industrial chemicals, but is not suitable for use in highly acidic environments.

The UCP bearing unit is a cast iron flange bearing unit equipped with a UC bearing and a grease nipple. This durable unit is attached to the base with two bolts, ensuring a solid installation. The bearing has retaining screws, which ensure stable operation and extend the service life. The UCP bearing unit is specially designed for the demanding needs of industry, where reliability and durability are of primary importance. Applications Industrial equipment, conveyor systems, manufacturing lines, machine shops Industries Metal industry, food industry, chemical industry, paper industry Benefits The UCP bearing unit offers excellent durability and easy installation, reducing maintenance costs and improving production efficiency. Risks If installed incorrectly, a bearing unit can cause noise and vibration, which can lead to premature wear of the equipment. Regular inspection and proper installation are key to avoiding problems. Chemical resistance The cast iron construction offers good resistance to common industrial chemicals.

Deep groove ball bearing 6200 series 2zr is designed to withstand heavy use in demanding industrial environments. This metal-shielded bearing offers reliable performance and long life, making it an ideal choice for many applications. The high-quality construction ensures excellent durability and low maintenance requirements. Contact us for a quote. Applications Industrial machinery, conveyor belts, electric motors, pumps Industries Mechanical engineering, automation, energy, transportation Benefits Deep groove ball bearing 6200 series 2zr offers excellent durability and reduces maintenance costs. Its reliability and long life make it an economical choice. Risks Incorrect installation or overloading of the bearing can lead to premature wear. Regular inspection and proper use will prevent problems.

Deep groove ball bearing 6200 series is designed for demanding industrial needs, offering durability and performance in heavy duty applications. This plastic-protected bearing is the ideal choice when a reliable and long-lasting solution is required. The compact and robust design ensures easy installation and versatile use. High-quality materials ensure excellent durability and performance. Applications Mechanical engineering, conveyor systems, electric motors, pumps. Industries Industry, manufacturing, automation, energy production. Benefits The 6200 series deep groove ball bearing offers excellent durability and low maintenance requirements. It is designed to operate reliably even in challenging conditions. Risks Choosing the wrong bearing can lead to premature wear and downtime. Expert selection and installation are key to minimizing risks.

The UCFL bearing unit is a cast iron flange bearing unit containing a UC bearing. This unit is designed to be mounted to the base with two bolts, ensuring a sturdy and durable installation. The bearing is equipped with retaining screws, which ensures reliable operation and reduces the need for maintenance. The UCFL bearing unit is an excellent choice for demanding industrial applications where durability and reliability are paramount. Applications Mechanical engineering, conveyor systems, industrial plants, production lines Industries Metal industry, food industry, chemical industry, logistics Benefits The UCFL bearing unit offers a long-lasting and reliable solution that reduces downtime and maintenance costs. Its simple installation and durable design make it an ideal choice for a wide range of industrial applications. Risks An incorrectly installed bearing unit can cause uneven loading, which can lead to premature wear. In addition, inadequate maintenance can reduce bearing performance and shorten its service life. Chemical resistance The cast iron construction allows for good durability in typical industrial environments, but is not recommended for highly corrosive chemicals.

The replacement bearing for Uc bearing units is designed to provide a reliable solution for demanding industrial applications. The spherical outer surface of the bearing and two retaining screws ensure a secure lock, allowing for easy installation and use. The inner collar is longer at the front of the bearing, which improves its durability and performance. This replacement bearing is compatible with a variety of bearing units, including UCF, UCFC, UCFL, UCP and UCT. Applications Industrial equipment, machine shafts, conveyor systems, pump units Industries Metal industry, chemical industry, food industry, paper industry Benefits This bearing offers excellent durability and long service life, reducing maintenance costs and improving operational reliability. Risks If installed incorrectly, a bearing can cause equipment malfunctions and additional costs. It is important to ensure that the bearing is installed correctly and is suitable for the intended use.

The Pos swivel head is designed to provide excellent mobility and flexibility for industrial hose connections. This male threaded swivel arm provides a reliable and long-lasting solution for demanding applications where precision and durability are required. The swivel head allows for easy hose installation and removal, making it an ideal choice for a variety of industrial environments. Its durable construction minimizes maintenance and maximizes service life. Applications Hose connection, fluid transfer, compressed air systems Industries Mechanical engineering, chemical industry, oil and gas sectors Benefits The Pos swivel head offers easy and quick installation and removal, saving time and effort. Its durable construction extends the life of the equipment and reduces downtime. Chemical and corrosion resistance The rod end is designed to withstand chemicals and corrosion effectively, making it suitable for demanding industrial environments.

The T-branch connector for compressed air is designed to provide an efficient and reliable solution for industrial compressed air systems. This high-quality connector allows for easy installation and is compatible with a variety of compressed air hoses, increasing its versatility in applications. The robust construction ensures longevity and reduces the need for maintenance, making it an ideal choice for professionals. Its innovative design improves work efficiency and ensures reliable operation. Applications Compressed air systems, industrial equipment, production lines for machine shops, compressed air solutions for construction sites. Industries Industry, construction industry, automotive industry, machine shops, production industry. Benefits The T-piece connector for compressed air offers durability and reliability. Compatibility with multiple hoses makes it a flexible solution for different needs. Chemical and corrosion resistance The durable material ensures excellent chemical and corrosion resistance, which extends the product's lifespan. Sealing The hose seals when pushed into the bottom of the connector. The hose can be removed from the connector by pressing in the ring and pulling the hose out. Finding the right size The hose seals when pushed into the bottom of the plug connector. The hose can be removed from the plug connector by pressing the ring in and pulling the hose out. The thread can be sealed with thread glue or Teflon tape.

The male thread push-in connector for compressed air offers a reliable and durable solution for industrial compressed air systems. This high-quality connector is designed to be compatible with a variety of compressed air hoses, allowing for versatile use in a variety of applications. Its robust construction ensures longevity and reduces maintenance, making it an excellent choice for professionals. Easy installation adds value and improves work efficiency. Applications Compressed air systems, industrial equipment, production lines for machine shops, compressed air solutions for construction sites. Industries Industry, construction industry, automotive industry, machine shops, production industry. Benefits The male thread of the push-in connector for compressed air offers longevity and reliability. Compatibility with a variety of hoses makes it a flexible solution for different needs. Chemical and corrosion resistance The durable material ensures excellent chemical and corrosion resistance, which extends the product's lifespan. Sealing The hose seals when pushed into the bottom of the plug connector. The hose can be removed from the plug connector by pressing the ring in and pulling the hose out. The thread seals against its o ring. Finding the right size In push-in fittings, the outer diameter of the hose determines the size of the fitting. So choose the push-in fitting according to the outer diameter of the hose.

The push-in connector for compressed air with internal thread offers a reliable and durable solution for industrial needs. This high-quality connector is compatible with a wide range of compressed air hoses, making it an excellent choice for a variety of applications. Its durable construction ensures longevity and reduces the need for maintenance. Easy installation and versatility make it an ideal part of compressed air systems. Applications Compressed air systems, procurement and replacement of hoses, transfer of compressed air. Industries Industry, construction industry, automotive industry, machine shops, production industry. Benefits The internal thread of the push-in connector for compressed air offers reliability and longevity. It is easy to install and compatible with a wide range of hoses. Chemical and corrosion resistance Made of high-quality material that is highly resistant to chemicals and corrosion, ensuring the longevity of the product. Sealing The hose seals when pushed into the bottom of the plug connector. The hose can be removed from the plug connector by pressing the ring in and pulling the hose out. The thread can be sealed with thread glue or Teflon tape. Finding the right size In push-in fittings, the outer diameter of the hose determines the size of the fitting. So choose the push-in fitting according to the outer diameter of the hose.

The push-in connector is designed to provide a reliable and durable solution for industrial applications. This high-quality connector is compatible with a wide range of compressed air hoses, making it an excellent choice for a variety of applications. Its durable construction ensures longevity and reduces maintenance. Easy installation and versatility make it an ideal part of compressed air systems. Applications Compressed air systems, procurement and replacement of hoses, transfer of compressed air. Industries Industry, construction industry, automotive industry, machine shops, production industry. Benefits Plug connector angle for compressed air, external thread provides reliability and longevity. It is easy to install and compatible with many different hoses. Chemical and corrosion resistance Made of high-quality material that is highly resistant to chemicals and corrosion, ensuring the longevity of the product. Sealing The hose seals when pushed into the bottom of the connector. The hose can be removed from the connector by pressing in the ring and pulling the hose out. Finding the right size In push-in fittings, the outer diameter of the hose determines the size of the fitting. So choose the push-in fitting according to the outer diameter of the hose.

The push-in elbow for compressed air is designed to provide an efficient and reliable solution for industrial compressed air systems. This durable connector allows for easy and secure installation at elbows, making it an ideal choice for complex hose arrangements. The push-in connector is made of high-quality materials that ensure long life and excellent performance. Its compact design saves space and improves hose handling. Applications Industrial compressed air systems, machine shops, service stations, production lines Industries Automotive industry, metal industry, food industry, chemical industry Benefits The push-in elbow for compressed air offers easy installation and excellent tightness, which reduces air loss and improves energy efficiency. Chemical and corrosion resistance Highly resistant to oils and other common industrial chemicals, making it versatile in a variety of environments. Sealing O-rings, Teflon seals Finding the right size In push-in fittings, the outer diameter of the hose determines the size of the fitting. So choose the push-in fitting according to the outer diameter of the hose.

The push-in connector extension for compressed air is designed to provide a reliable and durable solution for industrial compressed air systems. This extension connector allows for quick and easy connection, making it an ideal choice for busy work environments. Made from high-quality materials, it ensures a long service life and low maintenance. Compatible with a wide range of compressed air hoses, this connector is an efficient and practical part of any compressed air system. Applications Industrial compressed air systems, machine shops, installation work, maintenance and repair services Industries Manufacturing industry, automotive industry, construction industry, aerospace industry Benefits The push-in connector for compressed air offers quick connection and disconnection, saving time and reducing downtime. The durable construction ensures reliable operation even in demanding conditions. With this connector, you can easily extend compressed air hoses. Chemical and corrosion resistance The plug connector is highly resistant to common industrial chemicals, but is not suitable for use in highly corrosive environments. Sealing The hose seals the connector when it is pushed all the way to the bottom of the connector. Finding the right size In push-in fittings, the outer diameter of the hose determines the size of the fitting. So choose the push-in fitting according to the outer diameter of the hose.

The Phs rod end is a versatile and durable component designed for demanding industrial applications. This rod end with internal thread provides an easy and reliable connection to various devices and systems. Its high-quality construction ensures a long service life and low maintenance requirements, making it a cost-effective choice. The Phs rod end is ideal for applications where a flexible connection is required for moving or vibrating parts. Applications Industrial equipment, mobile machinery, hydraulic systems, vibration isolation. Industries Mechanical engineering, automation, transportation equipment industry, energy sector. Benefits The use of the PHS rod end reduces wear and extends the life of equipment. It also enables efficient and safe motion control in various industrial applications. Chemical and corrosion resistance The PHS rod end is designed to withstand a variety of chemicals and corrosion, making it ideal for demanding industrial environments.

Deep groove ball bearing 6000 series 2zr is designed to withstand demanding industrial environments. This metal-shielded bearing offers excellent performance and reliability, making it an ideal choice for harsh operating conditions. Its durable construction ensures long life and low maintenance. The optimal choice when reliable and efficient bearing is required. Applications Machinery, conveyor equipment, industrial production lines, electric motors Industries Automotive industry, food industry, metal industry, construction industry Benefits Deep groove ball bearing 6000 series 2zr offers excellent wear resistance and reduces downtime. Its metal protection ensures protection against dust and dirt. Risks If installed incorrectly, the bearing can cause excess friction and wear. Failure to maintain it can lead to premature failure.

The air extension connector is designed to provide a reliable and durable solution for industrial compressed air systems. This connector enables a seamless and secure connection in various compressed air applications, reducing the risk of leaks and improving system efficiency. Made of high-quality materials, it withstands even the most demanding operating conditions and offers a long service life. The extension connector is easy to install and compatible with hoses of various standards. Applications Industrial compressed air systems, machine shops, production lines, automation systems Industries Manufacturing industry, automotive industry, food industry, chemical industry Benefits The compressed air extension connector ensures an efficient and leak-free connection, reducing maintenance costs and optimizing system performance. Chemical and corrosion resistance High-quality materials ensure excellent resistance to chemicals and corrosion, extending the connector's service life in demanding environments. Finding the right size By measuring the outer diameter of the hose with a caliper, you can easily determine the size of the connector.

Nlp spherical plain bearing housing is designed to protect and support spherical plain bearings, ensuring their longevity and efficiency. Made of durable cast iron or steel, it protects the bearings from dust and dirt, while promoting heat dissipation. This component is a key part of a wide range of industrial applications, such as electric motors and gearboxes. It ensures the smooth and uninterrupted operation of your equipment. Applications Electric motors, gearboxes, hydraulic cylinders, industrial machinery Industries Industry, mechanical engineering, automation, energy industry Benefits The NLP spherical plain bearing housing extends bearing life and improves performance. It protects bearings from contaminants and helps control temperature. Risks Without the right spherical plain bearing housing, bearings can be subject to excessive wear and overheating, which can lead to equipment malfunctions. Contamination can also significantly shorten the life of bearings.

The GE spherical plain bearing is a high-quality solution for industrial applications, designed to withstand radial loads and misalignment. Its unique design provides a sliding alignment surface, making it an excellent choice for heavy static and variable loads. The bearing requires lubrication and has a lubrication groove on its outer ring for this purpose. This spherical plain bearing provides reliability and performance for demanding industrial applications. Applications Industrial equipment, mechanical engineering, heavy loads, compensation of alignment errors Industries Engineering industry, heavy industry, manufacturing industry, mining industry Benefits GE spherical plain bearings are highly resistant to heavy loads and misalignment, which extends the life of equipment and reduces the need for maintenance. Risks Insufficient lubrication can lead to premature wear, and if installed incorrectly, the bearing may not function optimally. Chemical resistance The GE spherical plain bearing offers good resistance to a wide range of industrial chemicals, making it a reliable choice for demanding environments.