The red mold hose is specially designed for mold cooling of injection molding machines. It is a durable and flexible solution made of high quality, red EPDM rubber and reinforced with fabric. Applications Mold cooling of injection molding machines, industrial heat transfer. Industries Industry, engineering industry, plastics industry. Benefits Mold hose red offers excellent heat resistance and durability, which reduces the need for maintenance and replacement. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Chemical resistance Made to withstand industrial chemicals, the hose offers reliability and longevity. Operating temperatures -20 °C to +140 °C Operating pressure classes Defined according to the intended use. Certificates and classes Defined according to the intended use. If you are looking for a durable and heat-resistant hose for industrial needs, ask for a quote for Moottiletku red. We offer comprehensive advice on choosing a hose, ensuring that you get a solution that suits your needs.

• Safety factor: 6 x nominal load • Standard: EN 13889 • Hot-dip galvanized • Operating temperature: -40°C – +200°C

Push lock hoses are durable and reliable solutions for industrial needs. They are specially designed for mold cooling of injection molding machines and can withstand high temperatures. Applications Mold cooling of injection molding machines, industrial plants, mechanical engineering. Industries Industry, mechanical engineering, equipment manufacturing. Benefits Push lock hoses offer durability and reliability at high temperatures, reducing the need for maintenance and replacement. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Chemical resistance Push lock hoses are made to withstand chemicals, providing reliability and longevity. Operating temperatures -20 °C to +140 °C Operating pressure classes Suitable for use in industrial pressure conditions. When you need reliable and durable hoses for industrial needs, ask for a quote on Push lock hoses. Our experts will help you find the right solution for your needs.

Mold hose blue is a very durable and reliable choice for various industrial needs. This rubber hose can withstand high temperatures and is specially designed for mold cooling of injection molding machines. Applications Mold cooling of injection molding machines, high temperature industrial processes. Industries Industry, manufacturing, engineering industry. Benefits Mold hose blue offers excellent heat resistance and reliability, which reduces the need for maintenance and replacement. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Adapters Molded hose blue is compatible with several standard connectors, which allows it to be integrated into a wide variety of systems. Chemical resistance The inner rubber is made of black EPDM rubber and the outer rubber is made of blue EPDM rubber, which offer excellent chemical resistance. Operating temperatures -20 °C to +140 °C Operating pressure classes Information not available. Ask for more information when requesting a quote. Certificates and classes Information not available. Ask for more information when requesting a quote. When you need a reliable and durable mold hose, ask for a quote for the Mold hose blue product. Our experts will be happy to help you choose a solution that suits your needs.

SHELL Gadus S2 high performance multipurpose grease.

SHELL Gadus S2 high performance multipurpose grease.

SHELL Gadus S2 high performance multipurpose grease.

SHELL Gadus S2 high performance multipurpose grease.

Hydraulic oil Shell Tellus 32.

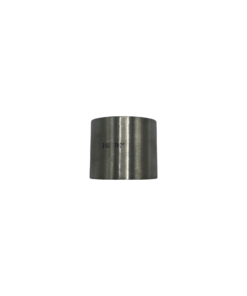

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar