A high-quality cylinder head gasket is a vital part of the hydraulic system, whose role is to prevent oil leakage and ensure efficient operation of the system. Our range includes high quality 63mm stem seals made from durable materials such as rubber, PTFE or PU. The design and size of the seals are precisely designed to fit the 63mm stem, so that they fit perfectly into the system used by the customer. Our seals are very durable and have a long service life. They can be used in many types of hydraulic systems where a seal is needed for a 63mm stem. The use of a high-quality seal reduces unnecessary maintenance costs and ensures the efficient operation of the system. In addition, the use of a high-quality seal improves the safety of the system, as it reduces the risk of oil leaks, which can cause dangerous situations in e.g. lifting equipment. Our range of 63mm stem seals are top quality and affordable. They are made of durable materials, so they last even in heavy use. By choosing a high-quality cylinder stem seal from us, you can be sure of the safety and efficiency of your system.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. It is important to note that gaskets designed for different sized stems are not interchangeable. For example, a 60mm stem seal is not suitable for a 40mm stem, as its dimensions and sealing ability are designed differently. That is why it is important to choose the right size and suitable seal for the size of the stem and the oil used. With the help of a high-quality stem seal, problems caused by oil leaks can be avoided, which can affect the operation and safety of the system. In summary, it can be stated that choosing the right stem seal is crucial for the operation of the hydraulic system. A high-quality stem seal helps to avoid unnecessary maintenance costs, increases the service life of the system and improves the safety of the system.

The hydraulic system consists of many different parts, one of the most central of which is the stem seal of the hydraulic cylinder. The stem seal is a necessary part of the system, as its job is to prevent oil leakage and ensure that the system works efficiently. Durable materials such as rubber, PTFE or PU are used as manufacturing materials, and the design and size of the stem seal are precisely designed to fit a 40mm stem. Choosing the right stem seal is crucial for the system to function safely and efficiently. With the help of a high-quality stem seal, unnecessary maintenance costs can be avoided and the service life of the system can be extended.

The hydraulic system consists of several different parts, and one of them is the stem seal of the hydraulic cylinder. The stem seal is an important part of the system, as its task is to prevent oil leakage and ensure the efficient operation of the system. Stem seals are made from durable materials, such as rubber, PTFE or PU, and the shape and size of the seal are precisely designed to fit a 40mm stem. Choosing the right stem seal is particularly important for the system to function safely and efficiently. A high-quality stem seal helps to avoid unnecessary maintenance costs and extends the service life of the system. In a search engine-friendly way, you can emphasize, for example, the importance of a high-quality stem seal for the safety and efficiency of the system.

The hydraulic system consists of several different parts, one of the most important of which is the hydraulic cylinder stem seal 36mm. The function of the stem seal is to prevent oil leakage and ensure efficient operation of the system. Durable materials such as rubber, PTFE or PU are used as the manufacturing material of the seal, and its design and size are carefully planned according to the size of the stem. Choosing the right stem seal is key for the system to work safely and efficiently. With the help of a high-quality stem seal, unnecessary maintenance costs can be avoided and the service life of the system can be extended.

The hydraulic system consists of many different parts, one of the most important of which is the hydraulic cylinder stem seal 35mm. The purpose of the seal is to prevent oil leakage and ensure efficient operation of the system. Durable materials such as rubber, PTFE or PU are used as manufacturing materials. The design and size of the seal is precisely designed according to the size of the stem. Choosing the right stem seal is important for the system to work safely and efficiently. A high-quality stem seal helps to avoid unnecessary maintenance costs and extends the service life of the system.

The hydraulic system is a complex entity consisting of several different parts. One of the most important parts is the stem seal of the hydraulic cylinder, whose task is to prevent oil leakage and ensure the efficient operation of the system. Hydraulic cylinder stem seals are made of durable materials, such as rubber, PTFE or PU, which can withstand various pressures and temperatures. The design and size of the seal is precisely designed to fit a specific size stem to ensure optimal performance and prevent oil leakage. The importance of the right choice of the stem seal of the hydraulic cylinder is great, because it affects the safety and efficiency of the system. For example, the stem seal intended for a 32mm stem is a necessary part of the system so that it functions optimally and oil leaks can be avoided. Choosing a high-quality hydraulic cylinder stem seal is important for efficient and safe operation of the system. A high-quality stem seal helps to avoid unnecessary maintenance costs and ensures a long service life of the system

The hydraulic system is a complex system consisting of many different parts. One of the most important parts is the stem seal of the hydraulic cylinder, which is responsible for preventing oil leakage and ensuring the efficient operation of the system. The hydraulic cylinder stem seal for a 30mm stem is made of durable materials, such as rubber, PTFE or PU, which can withstand high pressures and temperatures. The design and size of the seal is precisely designed to fit the 30mm stem, so that it works optimally and prevents oil leakage. Choosing the right hydraulic cylinder stem seal is very important to ensure efficient and safe operation of the system. The stem seal intended for the 20mm stem is particularly important, as it improves the efficiency of the system, increases its service life and reduces maintenance costs. If you need a hydraulic cylinder stem seal for a 30mm stem, it is important to choose a quality product designed to meet the needs of your system. A high-quality stem seal helps ensure the efficient operation of the system and prevents unnecessary oil leaks, saving time and money in the long run.

The hydraulic system is a complex and important part of many industrial and business processes. One of the most important parts of the system is the hydraulic cylinder stem seal for the 25mm stem, which is a crucial part that prevents oil from leaking from the hydraulic cylinder and keeps the system efficient and safe. The hydraulic cylinder stem seal for a 25mm stem is made of durable materials that can withstand high pressures and temperatures. The exact design and size of the seal ensure its suitability for the 25mm stem and its ability to prevent oil leakage. This is important, as oil leaks can lead to unnecessary maintenance work and costs. Choosing the right hydraulic cylinder stem seal is critical to the efficient operation of the hydraulic system. The stem seal intended for a 25mm stem improves the efficiency of the system, increases its service life and reduces maintenance costs. This leads to savings in the long term and ensures the optimal operation of the system. If you need a hydraulic cylinder stem seal for a 20mm stem, it is important to choose a high-quality product that meets the needs of your system. Choose a high-quality and properly selected product to ensure optimal operation of your hydraulic system and avoid oil leaks.

A hydraulic system is a complex system consisting of several parts. One of the most important parts is the stem seal of the hydraulic cylinder for the 22mm stem. This seal is very important as it prevents oil from the hydraulic cylinder from leaking outside. This ensures the efficient operation of the hydraulic system and avoids unnecessary oil leaks, which can lead to maintenance work and costs. The hydraulic cylinder stem seal for a 22mm stem is made of durable materials, such as rubber, PTFE or PU, which can withstand high pressures and temperatures. The design and size of the seal is designed to precisely fit the 22mm stem to prevent oil leakage and improve the performance of the hydraulic system. Choosing the right hydraulic cylinder rod seal is very important for the hydraulic system to function optimally. The stem seal intended for a 20mm stem improves the efficiency of the hydraulic system, increases its service life and reduces maintenance costs. That's why it's important to choose a high-quality and properly selected product to ensure the optimal functioning of your hydraulic system and avoid oil leaks. If you need a hydraulic cylinder stem seal for a 20mm stem, we recommend choosing a high-quality product that meets the needs of your hydraulic system. This helps improve the efficiency of the hydraulic system and reduce maintenance costs in the long run.

The hydraulic cylinder stem seal for the 20mm stem is an important part of the hydraulic system, which prevents oil from leaking from the hydraulic cylinder to the outside. This seal ensures the efficient operation of the hydraulic system and avoids unnecessary oil leaks, which can lead to maintenance work and costs. The hydraulic cylinder stem seal intended for a 20mm stem is made of durable materials, such as rubber, PTFE or PU, which can withstand high pressures and temperatures. The design and size of the seal is designed to precisely fit the 20mm stem to prevent oil leakage and improve the performance of the hydraulic system. Obtaining the right hydraulic cylinder stem seal is important for the hydraulic system to function in the best possible way. The stem seal intended for a 20mm stem improves the efficiency of the hydraulic system, increases its service life and reduces maintenance costs. If you need a hydraulic cylinder stem seal for a 20mm stem, choose a high-quality and properly selected product to ensure optimal operation of your hydraulic system and avoid oil leaks.

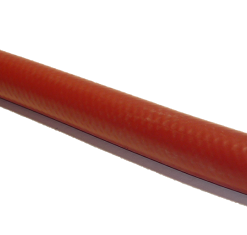

Non-reinforced silicone hose food grade is a high-quality and durable solution for non-pressure applications. It is made of silicone material that withstands high temperatures and keeps the product odorless and tasteless. The hose is also resistant to ozone and UV radiation, which makes it ideal for outdoor use. Applications Food industry, beverage industry, chemical industry. Industries Food industry, beverage industry, chemical industry. Benefits The silicone hose is very durable and versatile. It can withstand high temperatures and is odorless and tasteless. Risks Misuse or poor maintenance of the hose can lead to damage. It is important to follow the maintenance instructions. Chemical resistance Silicone tubing is resistant to a variety of chemicals, including ozone and UV radiation. Certificates and classes FDA 21 CFR 177.2600. When you need a reliable and durable silicone hose, contact us. We will be happy to help you find a solution that suits your needs.

The fabric-reinforced food-grade silicone hose is an excellent choice for industrial needs. It is highly flexible, chemical and heat resistant, and its inner and outer walls are made of durable material. This product is odorless, tasteless and FDA 21 CFR 177.2600 compliant, making it a reliable choice for the food industry. Applications Food industry, chemical industry, temperature-resistant applications. Industries Food industry, chemical industry, industrial hoses. Benefits This silicone hose is very durable and long-lasting, and its flexibility allows for versatile use. Risks Improper use or maintenance can lead to hose damage, so proper use and maintenance is important. Adapters The hose is compatible with several standard connectors. Chemical resistance Silicone tubing is chemical resistant, making it a reliable choice for many applications. Operating temperatures -60°C/+140°C Operating pressure classes Information not available Certificates and classes FDA 21 CFR 177.2600 Contact us for a quote on this great product.

Non-reinforced food grade silicone tubing is a high quality product designed to withstand high temperatures and chemicals. It is made of 100% silicone, is almost transparent and meets the strict standards of food approval. Applications Food industry and chemical industry. In food pumps, on the pressure side, when you want to see that the product is moving. Industries Food industry and chemical industry. Benefits The silicone food hose offers excellent resistance to high temperatures and chemicals, and meets the strict standards of food approval. Risks Misuse or careless handling can damage the hose and affect its performance. Adapters Compatible with many different connectors, well suited for clamp connections. A connector with a stainless sleeve can be pressed into this hose. Chemical resistance Silicone food hose is made to withstand high temperatures and chemicals. Certificates and classes FDA 21 CFR 177.2600, EU Directive 1935/2004, 3A Sanitation Standard Class II. Silicone food hose is a reliable and durable choice when a hose resistant to high temperatures and chemicals is needed. Request a quote today!

The sewer opening hose 1" for suction trucks is a high-quality and durable solution for industrial needs. This 200 bar pressure-resistant hose is specially designed for use in suction trucks and mobile equipment, and is delivered as a ready-to-use assembly. Applications Vacuum trucks, mobile equipment, sewer openings and sewer flushing. Industries Industry, construction, sewerage, environmental services, petrochemicals. Benefits Our hose offers high performance and durability, reducing the need for maintenance and replacement. This hose is delivered practically by the meter. Tell us the length and we'll squeeze the ends into it. The plastic hose has a very slippery surface and is easy to handle. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Adapters Compatible with several standard connectors, allowing integration into a wide range of systems. Chemical resistance Made to withstand extreme conditions, providing reliability and longevity. Operating temperatures -40 - +120 Operating pressure classes The working pressure of the hose is 200 bar and the explosion pressure is 510 bar. If you need a reliable and durable sewer opening hose of specific dimensions, contact our experts. We offer comprehensive advice on the selection of hoses, ensuring that you get a solution that suits your needs.

The drain opening hose 1/2" for suction trucks is a high-quality and durable choice for industrial needs. This 220 bar plastic drain opening hose is designed especially for use in suction trucks and mobile equipment. It has a slippery surface and is easily wound on a reel. The hose is delivered as a ready-to-use assembly, and you can choose the desired length from the table below . Applications Vacuum trucks, mobile equipment, drain opening and drain flushing. Industries Industry, sewer opening services, maintenance. Benefits The sewer opening hose 1/2" for suction trucks offers reliability and durability, reducing the need for maintenance and replacement. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Adapters Compatible with many standard connectors, allowing versatile use. Chemical resistance The hose is made to withstand industrial chemicals, providing reliability and longevity. Operating temperatures -40 - +120 Operating pressure classes Working pressure 240 bar and explosion pressure 550 bar. Contact our expert sales for more information or to request a quote.

Deep groove ball bearing 6300 series 2ZR is a high-quality bearing equipped with a durable metal shield. This bearing offers reliability and long service life in various industrial applications. It is designed to withstand demanding conditions and effectively reduce friction. The metal shield protects the bearing from dust and other contaminants, making it an excellent choice for demanding environments. Applications Industrial equipment, conveyor belts, electric motors, pumps Industries Automotive, manufacturing, energy, engineering Benefits Deep groove ball bearing 6300 series 2ZR offers excellent durability and performance, reducing the need for maintenance and improving equipment reliability. Risks Although the bearing is protected by a metal shield, its service life may be shortened if it is continuously exposed to extreme temperatures or humidity.

Top quality 6300 series deep groove ball bearing with metal shield.

Top quality 6300 series deep groove ball bearing with metal shield.

Top quality 6300 series deep groove ball bearing with metal shield.