0,00 € - 34,00 €42,67 € VAT 0%VAT 25.5%

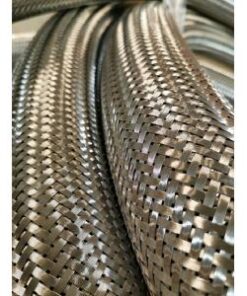

Full metal hose with steel braid is a strong, durable and long-lasting choice for many industrial needs. It is designed to withstand high temperatures and pressure, which makes it ideal for e.g. steam systems and chemical handling. The reliable hose for really high temperatures, where high pressure resistance is required from the hose.

Applications

Steam systems, compressed air transfer, chemical handling, heavy industry, district heat transfer, saturated steam.

Industries

Industry, chemical industry, manufacturing industry.

Benefits

All-metal hose with steel braid offers excellent durability and longevity, especially in conditions requiring high pressure and wear. Its temperature duration is -270°C to +600°C. Pressure range 8-125 Bar. The pressure class of the hose depends on the size of the hose and the temperature of the medium to be transferred. For higher pressures, you should choose an all-metal hose with a double braid.

Risks

The full metal hose is really light and flexible to use. Improper use or maintenance of the hose can lead to its damage and shorten its service life.

Adapters

The hose is compatible with several different connectors made of stainless or acid-resistant steel. In practice, almost any connector can be welded to the hose.

Chemical resistance

The inner material of the hose is crimped high-quality aisi316 steel, which is excellently resistant to chemicals.

Certificates and classes

AISI 316L - DIN 1.4404-Z2CN17-12, AISI 304 - DIN 1.4301-Z6CN18-09. All-metal hose with steel braid is a reliable choice that can withstand the demanding conditions of industry. Ask for an offer and make sure the product is right for your needs.