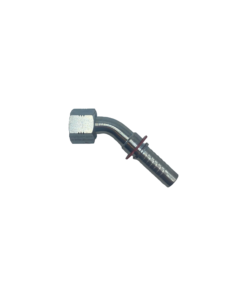

Hydraulics systems ORFS 90 degree elbow hose connector with internal thread. Steel and sturdy connector for all hydraulic hose assemblies. These connectors have a UN thread level with sealing. This connector requires a 90 Shore o-ring all the way to the outer thread of the connector. The o-ring in question should be replaced every time the connector needs to be replaced. Due to its structure, the connector is easy to thread. This nipple is available in many different sizes. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. The thread table of orfs connectors below shows the exact thread of the un connector.

ORFS hose connector for hydraulic systems with internal thread. Steel and sturdy connector for all hydraulic hose assemblies. These connectors have a UN thread level with sealing. This connector requires a 90 Shore o-ring all the way to the outer thread of the connector. The o-ring in question should be replaced every time the connector needs to be replaced. Due to its structure, the connector is easy to thread. This nipple is available in many different sizes. If choosing the right size or connector causes difficulties, we will help you quickly in the chat and by phone. The thread table of orfs connectors below shows the exact thread of the un connector.

The steel hose connector is designed to provide an efficient and durable solution for industrial needs. Made of high-quality steel, this connector withstands even the most demanding conditions and offers excellent corrosion resistance. The connector with external thread allows for easy and quick installation on various hoses. In addition, its spindle is weldable, which further increases its application possibilities. Applications Process industry, food industry, chemical industry, shipping Industries Oil and gas industry, chemical process industry, food production, shipping Benefits The steel hose connector offers excellent durability and reliability, ensuring a long service life and low maintenance requirements. Chemical and corrosion resistance The steel used as the material for manufacturing the connector offers excellent resistance to both chemicals and corrosion, making it an ideal choice for demanding industrial environments. Sealing We recommend using glue or Teflon tape to seal the thread. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.