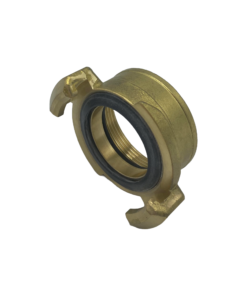

The brass fire connector is a high-quality connector specially designed for the diverse needs of industry. Its lightweight yet durable construction makes it an ideal choice for submersible pump use and other demanding applications. Equipped with an external thread and sealing ring, it ensures a reliable connection and longevity in various hose systems. Available with different claw spacing sizes, allowing for precise and safe installation. Applications Industrial plants, fire hydrants, submersible pumps, hose systems Industries Firefighting, industry, construction, water supply Benefits The fire hose connector offers a combination of lightness and durability, which facilitates installation and extends the product's service life. It ensures a reliable connection and reduces the risk of leaks. Risks An incorrectly selected connector size can cause leaks and an unreliable connection, which can lead to damage and downtime. It is important to check the gap carefully before installation. Hoses Compatible with fire hydrant hoses, submersible pump hoses and other industrial hoses Chemical resistance The hose connector of the fire connector is resistant to many chemicals used in industry, but it is recommended to check compatibility before use. Operating temperatures -20 to +80°C Operating pressure classes 10bar / 16bar Certificates and classes Made in Finland

The Fire Connector Internal Thread Brass is a high-quality connector designed to withstand demanding conditions. Made of aluminum, it is lightweight yet durable, making it an excellent choice for a variety of water and fire hydrant applications. Its internal thread and sealing ring ensure a reliable connection and easy installation. Careful measurement of the claw gap ensures optimal operation. Applications Fire hydrants, submersible pumps, water lines, pumps. Suitable for suction and pressure. Industries Industry, construction, municipal engineering Benefits The internal thread of the fire connector is lightweight and durable, making it easy to handle and install. It provides a reliable connection that can withstand even the most demanding operating conditions. Risks Choosing the wrong nail spacing can lead to loosening or leakage of the joint. Careful sizing and choosing the right size are essential to ensure safe use. Hoses Compatible connectors include standard-sized fire connectors and water line connectors. Chemical resistance The aluminum construction offers good corrosion resistance, but is not suitable for strongly acidic or alkaline environments. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar

The brass conversion fire connector is designed to facilitate the efficient connection of hoses of different sizes. This durable and reliable connector reduces installation time and improves work flow. If necessary, our experts can manufacture customized conversions for different connectors. Remember to check the claw spacing to ensure the correct size. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with a variety of industrial hoses, including 2", 3" and 4" connectors. Chemical resistance The brass construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The Palolitt diverter valve is designed for efficient and reliable hose branching in industrial applications. Made of high-quality Finnish aluminum, it combines the advantages of gate valves and ball valves. This diverter offers a durable solution that allows two hose lines to be connected to a main line. Available in two different models, it meets a variety of industrial needs. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with many industrial hoses and fire fittings. Chemical resistance The aluminum construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

The aluminum fire connector conversion is designed to make it easier to fit connections between different sizes of hoses. This durable and reliable connector allows you to effectively reduce the connection size, which reduces installation time and improves workflow. If necessary, our experts can manufacture customized conversions for different connectors. Remember to check the claw spacing to ensure the correct size. Applications Industrial plants, fire protection systems, liquid transfer. Industries Chemical industry, oil and gas industry, marine industry. Benefits The fire connector version offers flexibility and cost-effectiveness for connecting hoses of different sizes. It is easy to install and reduces the need for multiple specialized tools. Risks Incorrectly selected nail spacing can lead to leakage or failure of the joint under pressure. It is important to ensure the correct size and installation of the connector. Hoses Compatible with a variety of industrial hoses, including 2", 3" and 4" connectors. Chemical resistance The aluminum construction offers good resistance to most industrial chemicals, but is not suitable for highly corrosive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 16bar Certificates and classes No certifications or classes mentioned.

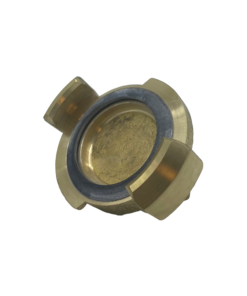

The brass fire connector plug is designed to provide a reliable and durable solution for demanding industrial needs. Its lightweight and durable construction makes it an ideal choice for submersible pumps, water lines and other industrial systems. The sealing ring ensures a tight connection, making it an excellent choice for critical systems. This product is widely used in Finnish fire hydrants, which highlights its suitability for fire safety. Applications Submersible pumps, water lines, fire hydrants, industrial systems Industries Industry, municipal engineering, fire safety Benefits The brass fire connector plug offers a lightweight yet durable solution for industrial needs, ensuring a tight and reliable connection. Its aluminum construction allows for easy handling and installation. Risks Selecting the wrong size can lead to leakage or unreliable connections. It is important to ensure the correct gap and compatibility of the connector with the application. Chemical resistance The aluminum construction is highly resistant to most chemicals used in industry, but it is recommended to check specific chemical cases before use. Operating temperatures -20 to +80°C Operating pressure classes 5bar / 16bar

The aluminum hose connector is designed to provide a reliable and durable solution for industrial needs. Made from high-quality aluminum, it combines lightness with excellent durability. The connector design allows for easy installation and ensures a tight connection. It is the ideal choice when you are looking for a long-lasting and efficient connector for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The aluminum hose connector provides a lightweight yet durable connection that can withstand harsh industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector can cause leaks or impair the function of the hose system. It is important to ensure that the connector is compatible with the hose being used. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The aluminum hose connector is designed to withstand a variety of industrial chemicals, but is not recommended for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar

Brass hose connector female thread is designed to meet the demanding industry standards. Made from high quality brass, this connector offers excellent durability and performance. Easy installation and a tight connection ensure reliable operation in a wide range of applications. The brass construction makes it a long-lasting and efficient solution for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The brass hose connector provides a durable connection that performs reliably in demanding industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector may cause leaks or impair system performance. Compatibility with the hose being used must be ensured. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The brass hose connector is resistant to many industrial chemicals, but is not suitable for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar Certificates and classes Fire connector used in Finland

The aluminum hose connector with internal thread is designed to meet the demanding needs of industry. Made from high-quality aluminum, this connector combines lightness and durability, making it an ideal choice for many applications. Easy installation and a tight connection ensure reliable operation. This connector is a long-lasting and efficient solution that is ideal for demanding conditions. Applications Industrial hose systems, fluid transfer, compressed air networks, chemical handling. Industries Process industry, chemical industry, food industry, engineering industry. Benefits The aluminum hose connector provides a lightweight yet durable connection that can withstand harsh industrial conditions, reducing maintenance costs and extending the life of the hose system. Risks If installed incorrectly, the connector can cause leaks or impair the function of the hose system. It is important to ensure that the connector is compatible with the hose being used. Hoses Compatible connectors include Camlock connectors, Storz connectors, Bauer connectors. Chemical resistance The aluminum hose connector is designed to withstand a variety of industrial chemicals, but is not recommended for use with highly corrosive substances. Operating temperatures -40 - +120°C Operating pressure classes 10bar / 16bar

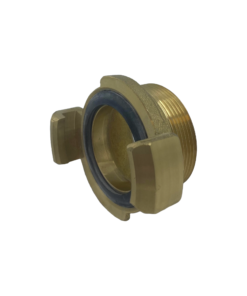

The brass fire connector male thread is designed specifically for industrial needs, providing a reliable and durable solution for various water lines and submersible pump applications. Its lightweight aluminum construction and male thread make it easy to handle and install. The sealing ring ensures a tight connection, which increases the versatility and application possibilities of the product. This connector type is commonly used in Finnish fire hydrants, which emphasizes its reliability and practicality. Applications water lines, submersible pumps, fire hydrants Industries industry, municipal engineering, fire protection Benefits The external thread of the fire connector offers a lightweight yet durable solution that allows for quick and easy installation. Its versatility makes it suitable for a variety of applications. Risks An incorrect fitting size can cause leaks or joint failure, so ensuring the correct size is important. Expert selection is the key to safe and efficient use. Chemical resistance The aluminum construction offers good resistance to most water and firefighting chemicals. Operating temperatures -20 - +80 Operating pressure classes 10bar / 16bar

The HEL-Performance clutch hose offers a smooth and precise feel, making it an excellent choice for the Tema Motocross Enduro 2002- model. The hose's nylon coating ensures durability and protects it from wear, allowing it to maintain its performance for a long time.

The hoses are manufactured with meticulous attention to detail and 15 years of experience by a brake hose doctor at Porvoo. So you can rely on the craftsmanship of over 50,000 manufactured hoses with every braking action.

Model designation: - Seal of approval: - Layout: Note: When ordering this product you will receive factory-measured, fully assembled steel braided hoses. If you would like to create custom-measured hoses, you can do so. hereIf you need help choosing the right hose, you can get a quick answer from the brake hose doctor in the chat.

The HEL-Performance front brake hose is specially designed for the Tema Motocross / Enduro 2002- model. This top quality hose offers excellent braking feel and durability in demanding conditions. The nylon coating ensures longevity and protects the hose from wear. Whether you are riding off-road or on the road, this hose provides confidence and precision in braking.

The hoses are manufactured with meticulous attention to detail and 15 years of experience by a brake hose doctor at Porvoo. So you can rely on the craftsmanship of over 50,000 manufactured hoses with every braking action.

Model designation: - Seal of approval: EBE Layout: Similar to the original Note: When ordering this product you will receive factory-measured, fully assembled steel braided hoses. If you would like to create custom-measured hoses, you can do so. hereIf you need help choosing the right hose, you can get a quick answer from the brake hose doctor in the chat.Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. In summary, it can be stated that choosing the right stem seal is crucial for the operation of the hydraulic system. A high-quality stem seal helps to avoid unnecessary maintenance costs, increases the service life of the system and improves the safety of the system. This applies to all stem sizes, such as a 120mm stem seal.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using a 95mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using an 85mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using a 100mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

The importance of the 90mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit the 90mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 70mm stem seal, you can avoid unnecessary maintenance costs and extend the life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 90mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 80mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 80mm stem seal, you can avoid unnecessary maintenance costs and extend the service life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 80mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 70mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 70mm stem seal, you can avoid unnecessary maintenance costs and extend the life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 70mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 65mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 65mm stem seal, you can avoid unnecessary maintenance costs and extend the service life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 65mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.