Tapered roller bearing 30300 series is designed to provide reliable performance in various industrial applications. This bearing series is specially developed to withstand heavy loads and demanding operating conditions, making it an ideal choice for industrial applications. Its innovative design allows for effective lubrication and low friction, which extends the bearing's service life. The precise manufacturing process of the tapered roller bearing guarantees its reliability and quality. Applications Industrial equipment, mechanical engineering, conveyor lines, power transmission systems. Industries Metal industry, mining industry, automotive industry, energy production. Benefits The 30300 series tapered roller bearing offers long-life performance and reduced maintenance under heavy loads. Its precise and durable design enables reliable operation in demanding industrial environments. Risks If installed or maintained incorrectly, the service life of the bearing can be significantly reduced. In addition, the ingress of contaminants into the bearing can cause malfunctions and damage. Chemical resistance The tapered roller bearing is resistant to most industrial lubricants and solvents, but it is recommended to check compatibility with specific chemicals.

Tapered roller bearing 32200 series is designed to withstand high radial and parallel axial loads. The bearings are usually mounted opposite each other with the same type of bearings, which maximizes their load capacity. The load capacity depends on the mounting system and the contact angle of the bearings, making them an excellent choice for many industrial applications. This bearing series offers reliability and performance in demanding conditions. Applications Electric motors, gearboxes, shafts, conveyor systems, industrial equipment Industries Mechanical engineering, automotive industry, energy industry, mining industry, transportation industry Benefits Tapered roller bearings offer excellent load capacity and long service life, making them suitable for demanding industrial environments where reliability and efficiency are required. Risks If installed incorrectly, bearings can cause premature wear and failure. It is important to follow the installation instructions carefully and ensure the correct contact angle. Chemical resistance Tapered roller bearings are highly resistant to many industrial chemicals, but it is recommended to check compatibility with specific chemicals.

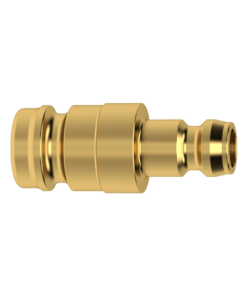

The quick-fit connector plug version 9mm - 13mm is designed to provide a reliable and durable solution for industrial needs. Made of high-quality brass, it ensures excellent durability and compatibility with other similar female connectors. This plug is especially suitable for use with heat-resistant rubber hoses, offering versatile application possibilities. Made in Germany, which guarantees high quality and precision. Applications: Industrial equipment, mold cooling systems, fluid transfer lines, heat-resistant applications Industries: Plastics industry, engineering industry, chemical industry, automotive industry Benefits: Excellent compatibility and easy installation make this plug an ideal choice for demanding industrial environments. Durable brass construction ensures long life and reliable operation. Chemical and corrosion resistance: Brass construction offers good resistance to most chemicals and corrosion, making it suitable for many industrial applications.

Tapered roller bearing 30200 series is designed to withstand demanding industrial conditions, providing reliability and longevity. This top quality bearing is especially suitable for heavy duty use and is an excellent choice for industrial applications. The bearing is easy to install and is compatible with a wide range of equipment. Contact our sales for more information and to request a quote. Applications Machine shops, production lines, transportation systems, heavy vehicles Industries Metal industry, automotive industry, mechanical engineering, logistics Benefits Tapered roller bearing 30200 series offers excellent wear resistance and reduces maintenance costs in the long term. Risks Incorrect installation can shorten the life of the bearing and negatively affect its performance.