The low pressure reducing nipple is designed for industrial requirements, providing a reliable connection in low pressure systems. Its durable construction ensures longevity and reduces the need for maintenance. Made from high-quality materials, the reducing nipple is suitable for a wide range of applications. Easy installation and compatibility with many hose types make it a versatile choice. Applications Compressed air systems, water systems, industrial process piping Industries Chemical industry, food industry, engineering industry Benefits The low pressure reducing nipple ensures a tight and secure connection, reducing the risk of leaks and improving system efficiency. Chemical and corrosion resistance Highly resistant to most common industrial chemicals and provides excellent protection against corrosion. Sealing The thread is sealed with Teflon tape or thread glue. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The Y-branch female threads is a robust brass connector designed to efficiently split liquid and gas lines. It offers excellent resistance to fuels, compressed air and water. This makes it an ideal choice for a wide range of industrial applications where reliability and durability are paramount. The Y-branch female threads are easy to install and allow for versatile use. Applications Liquid distribution, branching of gas lines, compressed air systems Industries Oil and gas industry, automotive industry, chemical industry Benefits The Y-branch internal threads offer a reliable and durable solution for demanding industrial applications. Its versatility and durability make it an excellent choice for many uses. Risks If the product is not installed correctly, it can lead to leaks or pressure losses. It is important to ensure that the fitting is compatible with the material being used. Hoses Compatible connectors include brass and steel hose connectors. Chemical resistance The brass construction offers good resistance to many fuels and chemicals, but it is important to ensure compatibility before use. Operating temperatures -20 - +120°C Operating pressure classes 10 bar / 30 bar Certificates and classes No certifications or classes mentioned.

The cross fitting with internal threads is a versatile and durable solution for industrial hose connections. Made of nickel-plated brass, this fitting offers excellent corrosion resistance and is particularly suitable for water, compressed air and fuels. Its internal threads allow for an easy and tight connection that will withstand even the most demanding conditions. This makes the cross fitting an ideal choice for industrial professionals looking for a reliable connection solution. Applications Water, compressed air, fuels Industries Industry, automotive, marine Benefits The cross connector with internal threads offers excellent durability and versatility, making it a reliable choice for various applications. Risks An incorrectly installed connector can cause leaks or pressure losses, which highlights the importance of professional installation. Chemical resistance Nickel-plated brass offers good chemical resistance, especially to water and fuels. Operating temperatures -20 - +100°C Operating pressure classes 6bar / 18bar

The threaded extension fitting is a high-quality component designed for the demanding needs of industry. Made of nickel-plated brass, this fitting offers excellent durability and corrosion resistance. It is compatible with a variety of fluids, including compressed air, fuels and water. The threaded design ensures an easy and tight connection. Applications Compressed air systems, fuel supply, water systems Industries Industry, engineering, marine industry Benefits The threaded extension connector provides a reliable and tight connection, reducing the risk of leaks and improving system efficiency. Risks If installed incorrectly, the fitting can cause leaks, and it is important to choose the correct size and material for the application. Hoses Quick connectors, compression connectors, thread locks Chemical resistance Nickel-plated brass is very resistant to a wide range of chemicals, but it is recommended to check compatibility with specific chemicals. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar

AN connector 90° angle is designed to meet the demanding needs of industry, offering excellent sealing and durability. This connector is an ideal choice for applications where reliable and leak-proof hose and pipe connections are required. Its black color and robust construction ensure long-lasting use, and the available size options ensure compatibility with various systems. AN connector 90° angle is a great choice for industrial professionals who value quality and performance. Applications In tuning and rally car engines, industrial piping, hydraulic systems Industries Rally, automotive industry, engineering industry, hydraulics Benefits The AN connector 90° elbow provides excellent sealing and a durable connection suitable for demanding industrial applications. Available size options allow for wide compatibility. Chemical and corrosion resistance The AN connector 90° elbow is highly resistant to chemical exposure and corrosion, ensuring reliable use in demanding environments. Sealing The connector seals its cone to the mating piece, ensuring a leak-free connection. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

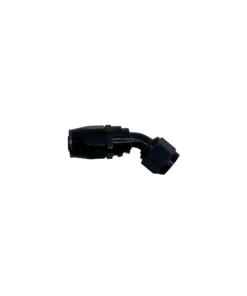

The AN hose connector 45° is designed specifically for industrial applications where a precise and durable connection is required. This connector offers flexibility for installation applications where traditional connectors are not sufficient. Its 45 degree angle allows for easy installation and is suitable for a wide range of applications. The durable construction ensures reliable operation even in challenging conditions. Applications Hose installation, confined spaces, repair projects Industries Automotive and motorsport, industry, machine shops Benefits The 45-degree angle improves space utilization by enabling efficient installations. The durable construction and high-quality materials ensure a long service life. Chemical and corrosion resistance The AN hose connector 45° is resistant to chemicals and corrosion, which extends its service life in demanding environments. Sealing The connector only seals its cone to the body. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

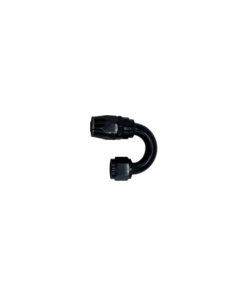

The AN 180° elbow is a high-quality connector designed to withstand the demanding conditions of motorsports. This connector provides a reliable and leak-free connection between hoses and piping, making it an ideal choice for a wide range of applications. Its black color and durable construction ensure long-lasting use, and the available size options ensure compatibility with different needs. The AN 180° elbow is an excellent choice for industrial professionals who value quality and reliability. Applications In tuning and rally car engines Industries Rally, acceleration devices such as motorboats, acceleration cars, motorcycles Benefits The AN connector 180° elbow offers a reliable connection and versatile use in industrial applications. The wide range of sizes allows for seamless connection of various hoses and pipes. Chemical and corrosion resistance The AN connector 180° angle withstands demanding chemical environments and corrosion, ensuring long-lasting and reliable use. Sealing The connector seals its cone to the mating part. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The AN straight hose connector is a versatile and durable solution, especially for motorsport needs. Available in several sizes, it ensures a leak-free and reliable connection between hoses and pipes. The black colored connector is designed to withstand demanding conditions, providing a long-lasting connection. Its ease of use and reliable functionality make it particularly suitable for a wide range of industrial needs. Applications In tuning and rally car engines Industries Rally and acceleration equipment such as motorboats, acceleration cars and motorcycles Benefits The AN double nipple provides a reliable and durable connection for many industrial applications. A wide range of sizes ensures compatibility with a variety of hoses and piping. Chemical and corrosion resistance The AN double nipple is designed to withstand demanding chemical environments and corrosion, ensuring long-lasting functionality. Sealing The connector seals its cone to the mating part. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The AN hose connector with 150° angle is designed specifically for the demanding needs of industry, where a precise and durable connection is required. This black connector offers excellent flexibility in tight installation areas where traditional connectors are not efficient enough. Its 150 degree angle improves installation options and is suitable for a variety of different applications. The connector's durable construction ensures long-lasting and reliable use even in challenging conditions. Applications Hose installation, confined spaces, repair projects Industries Automotive and motorsport, industry, machine shops Benefits The 150 degree angle optimizes space utilization, allowing for installations in tight spaces. High-quality materials provide excellent durability and performance. Chemical and corrosion resistance The AN hose connector 150° has excellent resistance to chemical agents and corrosion, which extends its service life in demanding conditions. Sealing The connector only seals its cone to the body. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

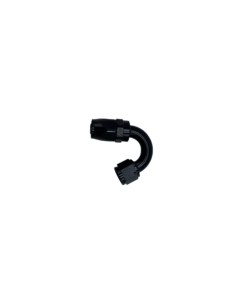

The AN hose connector 120° is designed to provide an efficient and secure connection, especially in challenging installation situations where space is limited. This high-quality black connector is optimized for AN connectors and its unique 120 degree angle increases installation flexibility compared to traditional right-angle connectors. The connector's design allows it to be used in a variety of applications in tight engine spaces, providing reliability and longevity in demanding conditions. For motorsports professionals, this connector is the best choice when durability and versatility are needed for hose connections. Applications Hose installation, confined spaces, repair projects Industries Car and motorsports Benefits The 120 degree angle allows for connection in tight spaces and increases installation flexibility. High-quality materials ensure long service life and corrosion resistance. Chemical and corrosion resistance The AN hose connector 120° is designed to withstand demanding chemical environments and the effects of corrosion, which increases its reliability and service life. Sealing The connector only seals its cone to the body. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.