Fuel/oil hose 10bar is a reliable and durable choice for industrial needs. Its reinforced structure and excellent chemical resistance make it an ideal choice for handling both fuels and oils. Applications Machinery, equipment, oil and fuel transfer. Industries Industry, workshops, warehouses. Benefits The hose's excellent chemical resistance and reinforced structure guarantee a long service life and reliability. Risks Improper use or maintenance can lead to hose damage and leaks. Adapters Compatible with many standard connectors. Chemical resistance Aromatic resistance 50%, excellent for oils and other hydrocarbons. Operating temperatures -35 °C to +90 °C Operating pressure classes 10 bar Contact us to get an offer for the Fuel/oil hose 10 bar product.

Rubber sanitary hose is a top-class product, specially designed for waste water pipes in boat toilet systems. Made from high-quality materials, this hose guarantees longevity and reliability. Its highly flexible design effectively prevents the spread of unpleasant odors from the toilet, making it an ideal choice for boat building. Applications Boat toilet systems, waste water pipes. Industries Marine industry, boat building, sanitary supplies. Benefits This sanitary hose offers longevity and reliability, and keeps toilets odor-free. Risks Improper installation or maintenance can reduce the life and efficiency of the hose. Hoses Compatible with many different toilet systems. Chemical resistance The hose is resistant to ozone, UV radiation and salt water. Operating temperatures -40 - +100. Certificates and classes EUROPEAN FDA, ISO 8099 : 2000.

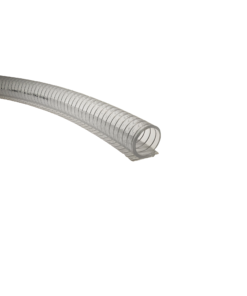

The transparent bilge suction hose is designed for draining the bilge of boats, offering excellent durability and transparency, making it easy to monitor the flow. This PVC suction hose is equipped with a steel spiral, which allows the hose to be flexible and durable at sharp angles. Its transparent design makes it the ideal choice when it is necessary to monitor the flow of liquids. Optimal for clamp connections, the hose provides a reliable and durable connection in various applications. Applications Pump suction hose, pressure hose for low pressures. As a bilge hose for boats. Industries Industry, food industry, chemical industry, boat building. Benefits The PVC suction hose is a durable and reliable solution that meets the requirements of the EU 10/2011 A, B, C food quality standard. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Adapters Compatible with various types of clamp connections. Chemical resistance Made to withstand various industrial chemicals, our hoses offer reliability and longevity. Certificates and classes EU 10/2011 A, B, C food quality standard.

The bilge suction hose is designed to provide a flexible and durable solution for boats. This hose is especially good for boat piping, where its extreme flexibility and durability come into play. The bilge suction hose is compatible with a variety of standard fittings, making it a versatile choice for a variety of applications. Its durable construction ensures reliable use and longevity. Applications Confined spaces, fuel hoses, bilge, oil return hoses, refueling hoses for boats and equipment. Industries Industry, shipping, boatbuilding. Benefits The extreme flexibility of the bilge suction hose allows it to be used in confined spaces, and its durable construction ensures a long service life. Risks Improper installation or maintenance can lead to hose damage and leaks, so proper use and maintenance is important. Adapters Compatible with many standard connectors. Chemical resistance Made to withstand various chemicals, which guarantees the longevity of the product. Operating temperatures -35 °C/+100 °C Operating pressure classes 5 bar / 15 bar Contact us and request a quote for a bilge suction hose. Our experts will be happy to help you choose the right solution for your needs.

Rubber drinking water hose specially designed for drinking water in water dispensers, boats and mobile homes. The hose is a hygienic, reliable and, above all, long-lasting solution for transporting drinking water. This hose is specially designed for drinking water needs and is compatible with many different fittings. Applications Drinking water transfer, water dispensers. Industries Food industry, event organizers and boats and caravans. Benefits The rubber drinking water hose offers excellent chemical resistance and is designed to withstand high operating temperatures. Risks Improper use or maintenance can lead to hose damage and leaks, so proper use and maintenance is very important. Adapters Compatible with many standard connectors. Chemical resistance Excellent chemical resistance, which guarantees the hose's longevity and reliability. Operating temperatures -40 to +70 degrees. Operating pressure classes 10 bar / 30 bar. Certificates and classes KTW-A, DVGW W270, European Regulation 10/2011 (simulants ABC-D1) Ask for a quote for a rubber drinking water hose and make sure you get a solution that fits your needs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. In summary, it can be stated that choosing the right stem seal is crucial for the operation of the hydraulic system. A high-quality stem seal helps to avoid unnecessary maintenance costs, increases the service life of the system and improves the safety of the system. This applies to all stem sizes, such as a 120mm stem seal.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using a 95mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using an 85mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. If you are using a 100mm stem, it is important to choose the right size stem seal. With the help of a high-quality and durable seal, oil leaks can be avoided and the efficient and safe operation of the system can be ensured. It is recommended to choose a gasket that is specially designed for the 100mm stem, so that it fits precisely on the surface of the stem and can withstand the effects of high pressure and temperature. Careful selection of the stem seal can ensure the functionality of the system and avoid unnecessary maintenance costs.

The importance of the 90mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit the 90mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 70mm stem seal, you can avoid unnecessary maintenance costs and extend the life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 90mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 80mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 80mm stem seal, you can avoid unnecessary maintenance costs and extend the service life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 80mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 70mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 70mm stem seal, you can avoid unnecessary maintenance costs and extend the life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 70mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

The importance of the 65mm stem seal for the hydraulic cylinder is very important, as it ensures the efficient and safe operation of the hydraulic system. The shaft seal is an essential part of the hydraulic system, as its role is to prevent oil leakage and ensure that the system operates smoothly and cost-effectively. The 65mm stem seal is precisely designed to fit a 65mm stem so that it fits perfectly on the stem. Its manufacturing materials use high-quality, durable materials such as rubber, PTFE or PU, which are oil and wear-resistant. This guarantees the durability and long service life of the stem seal. By choosing the right size and quality 65mm stem seal, you can avoid unnecessary maintenance costs and extend the service life of the system. A high-quality shaft seal also helps to avoid oil leaks, which can cause dangerous situations and negatively affect the operation of the system. In summary, it can be stated that the importance of the 65mm stem seal for the hydraulic cylinder is important, as it ensures the efficient and safe operation of the hydraulic system. By choosing a high-quality and correctly sized stem seal, you can avoid unnecessary maintenance costs and improve the operation and service life of the system.

A high-quality cylinder head gasket is a vital part of the hydraulic system, whose role is to prevent oil leakage and ensure efficient operation of the system. Our range includes high quality 63mm stem seals made from durable materials such as rubber, PTFE or PU. The design and size of the seals are precisely designed to fit the 63mm stem, so that they fit perfectly into the system used by the customer. Our seals are very durable and have a long service life. They can be used in many types of hydraulic systems where a seal is needed for a 63mm stem. The use of a high-quality seal reduces unnecessary maintenance costs and ensures the efficient operation of the system. In addition, the use of a high-quality seal improves the safety of the system, as it reduces the risk of oil leaks, which can cause dangerous situations in e.g. lifting equipment. Our range of 63mm stem seals are top quality and affordable. They are made of durable materials, so they last even in heavy use. By choosing a high-quality cylinder stem seal from us, you can be sure of the safety and efficiency of your system.

Choosing the right stem seal is very important for the operation of the hydraulic system. The stem seal is a necessary part of the system, as its role is to prevent oil leakage and ensure that the system works efficiently. If the gasket is the wrong size or not suitable for the oil being used, it can lead to oil leaks and inefficient system operation. Such problems can cause significant damage to system components and increase unnecessary maintenance costs. Choosing a high-quality stem seal is also important for the safety of the system. An incorrectly selected or low-quality seal can cause oil leaks, which can affect the operation and safety of the system. For example, an oil leak in a lifting device can cause dangerous situations if the object being lifted accidentally falls due to the leak. It is important to note that gaskets designed for different sized stems are not interchangeable. For example, a 60mm stem seal is not suitable for a 40mm stem, as its dimensions and sealing ability are designed differently. That is why it is important to choose the right size and suitable seal for the size of the stem and the oil used. With the help of a high-quality stem seal, problems caused by oil leaks can be avoided, which can affect the operation and safety of the system. In summary, it can be stated that choosing the right stem seal is crucial for the operation of the hydraulic system. A high-quality stem seal helps to avoid unnecessary maintenance costs, increases the service life of the system and improves the safety of the system.

The hydraulic system consists of many different parts, one of the most central of which is the stem seal of the hydraulic cylinder. The stem seal is a necessary part of the system, as its job is to prevent oil leakage and ensure that the system works efficiently. Durable materials such as rubber, PTFE or PU are used as manufacturing materials, and the design and size of the stem seal are precisely designed to fit a 40mm stem. Choosing the right stem seal is crucial for the system to function safely and efficiently. With the help of a high-quality stem seal, unnecessary maintenance costs can be avoided and the service life of the system can be extended.

The hydraulic system consists of several different parts, and one of them is the stem seal of the hydraulic cylinder. The stem seal is an important part of the system, as its task is to prevent oil leakage and ensure the efficient operation of the system. Stem seals are made from durable materials, such as rubber, PTFE or PU, and the shape and size of the seal are precisely designed to fit a 40mm stem. Choosing the right stem seal is particularly important for the system to function safely and efficiently. A high-quality stem seal helps to avoid unnecessary maintenance costs and extends the service life of the system. In a search engine-friendly way, you can emphasize, for example, the importance of a high-quality stem seal for the safety and efficiency of the system.

The hydraulic system consists of several different parts, one of the most important of which is the hydraulic cylinder stem seal 36mm. The function of the stem seal is to prevent oil leakage and ensure efficient operation of the system. Durable materials such as rubber, PTFE or PU are used as the manufacturing material of the seal, and its design and size are carefully planned according to the size of the stem. Choosing the right stem seal is key for the system to work safely and efficiently. With the help of a high-quality stem seal, unnecessary maintenance costs can be avoided and the service life of the system can be extended.