Female camlock hose coupling teflon coating is designed to provide a fast and secure connection in demanding industrial environments. This camlock coupling has been specially developed for the needs of the chemical industry, providing a tight and smooth connection even for aggressive acids. Its teflon coating ensures excellent durability and longevity. Reliability and easy installation make it a first-class choice for industrial professionals. Applications Chemical industry, mining industry, port operations. Industries Industry, mining, ports. Benefits This connector provides a tight and smooth connection that is very safe and secure when used correctly. Chemical and corrosion resistance The Teflon coating effectively protects the connector from chemical effects and corrosion, making it particularly suitable for demanding industrial environments. Sealing NBR as standard, Teflon / PTFE coated.

The clamp hose connector with mandrel is specially designed for demanding industrial needs, where a reliable and durable connection to rubber hoses is required. Made of high-quality AISI 316 material, this mandrel with external thread meets the requirements of DIN EN 14 420-5. Its excellent chemical resistance and long service life make it an ideal choice for various industrial applications. The clamp hose connector with mandrel is easy to install and disassemble, allowing it to be reused. Applications Industrial applications, rubber hose connections, machine and equipment connections. Industries Industry, chemical industry, food industry, shipbuilding. Benefits The clamp hose connector with a mandrel provides a reliable and long-lasting connection that reduces maintenance and saves costs. Its design allows for easy disassembly and reuse. Chemical and corrosion resistance Thanks to the AISI 316 material, the connector is highly resistant to chemicals and corrosion, ensuring a long service life even in demanding conditions. Sealing Suitable for use with multiple sealing methods, such as O-rings or sealants. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

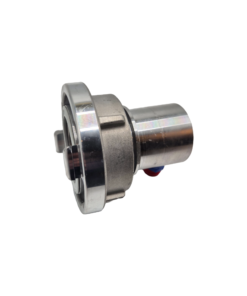

Tri clamp hose couplings are a popular choice among industry professionals, especially in the food industry. This coupling allows for quick and easy connections, which improves process efficiency and ensures a high level of hygiene. Made from high-quality stainless steel, it is durable and easy to clean. Tri clamp hose couplings meet the highest industry standards, providing reliability and efficiency. Applications Food industry processes, breweries, dairy processing, beverage manufacturing Industries Food industry, brewing industry, dairy industry, chemical industry Benefits The Tri Clamp hose connector offers quick installation and removal, reducing downtime. Its hygienic level and durability ensure a long service life. Chemical and corrosion resistance The stainless steel connector is highly resistant to chemicals and corrosion, which extends its service life. Sealing Suitable seals can be, for example, silicone rubber or EPDM, which provide a tight and reliable seal.

The Storz clamp hose coupling is a top-of-the-line solution designed to withstand the harsh conditions of industry. This aluminium coupling is equipped with an NBR seal and clamp spindle, ensuring reliability and longevity. Its versatile application options make it an ideal choice for the needs of various industrial sectors. Request a quote and ensure that you have a high-quality and durable hose coupling. Applications Industry, buildings, ships, agriculture. Industries Industry, construction, shipping, agriculture. Benefits The Storz clamp hose connector offers excellent durability and reliability, reducing maintenance and saving costs. Chemical and corrosion resistance The connector, made of aluminum, is resistant to many chemicals and offers good corrosion resistance. Sealing NBR seal.

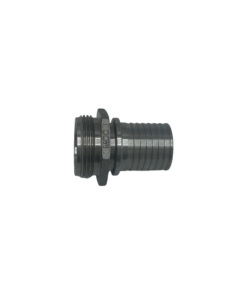

The plastic clamp hose connector is designed to provide a reliable and durable solution for industrial needs. Made from high-quality PP material, it is excellently suited for rubber hoses and offers longevity and reduces the need for maintenance. The connector is designed for easy disassembly and reuse, making it a cost-effective choice. Applications Industrial rubber hose connections where reliability and durability are required. Industries An industry where hose procurement and replacement are essential. Benefits The hose connector offers reliability and longevity, reducing maintenance needs and costs. It is disassembled and reusable, which increases its application possibilities. Chemical and corrosion resistance The plastic Polypropylene material ensures high chemical resistance, which extends the product's service life and improves its performance in demanding conditions. Sealing Suitable for use with various sealing materials.

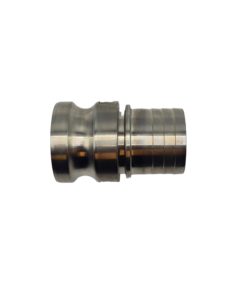

The male camlock clamp mandrel is designed to ensure a fast and reliable connection in demanding industrial applications. This connector offers easy installation and removal without the need for separate tools, making it an ideal choice for busy work environments. Made of durable material, it ensures a long service life and excellent pressure resistance. Compatibility with various hoses increases its versatility and application possibilities. Applications Fluid transport, chemical processes, water distribution, industrial equipment connections Industries Chemical industry, food industry, maritime industry, energy sector Benefits The male camlock clamp spindle offers quick connection and disconnection without tools, reducing downtime and improving efficiency. Its durable construction ensures long service life even in demanding conditions. Chemical and corrosion resistance Made from durable materials, this connector offers good protection against the effects of chemicals and corrosion, making it suitable for challenging industrial environments. Sealing Suitable for use with PTFE, VITON, EPDM, NBR seals, which ensure a leak-free connection.

Female camlock clamp mandrel AISI 316 is designed to provide a reliable and durable connection for industrial applications. Made from high quality AISI 316 stainless steel, it offers excellent corrosion resistance in harsh environments. This connector is the ideal choice when you need a quick and secure connection without the need for tools. Its simple design allows for easy use and reduces installation time. Applications Industrial plants, chemical processes, oil and gas industry, maritime transport. Industries Chemical industry, food industry, marine industry, oil refining. Benefits Quick and easy installation without tools, excellent corrosion resistance and longevity. Chemical and corrosion resistance AISI 316 material offers exceptional resistance to a wide range of chemicals and corrosion, extending the connector's service life in demanding conditions. Sealing Suitable for use with PTFE and EPDM seals, which ensure a tight and secure connection.

The SMS male hose connector is designed to provide a reliable and durable solution for industrial applications. Made from high-quality materials, this connector ensures safe and efficient fluid transfer in the food and beverage industry. The innovative design ensures a secure connection and easy installation. Its reliability makes it an ideal choice for demanding environments. Applications Food and beverage industry, dairy processing, breweries. Industries Food industry, beverage industry, chemical industry. Benefits The SMS male spindle food connector offers excellent corrosion resistance and ensures a secure connection in food contact applications. Chemical and corrosion resistance Made from durable materials that provide excellent protection against chemical wear and corrosion, extending the life of the connector. Sealing Suitable for use with FDA approved seals such as EPDM and FKM. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The SMS female hose connector is designed to meet the highest hygiene standards in the food industry. This high-quality connector ensures the safe and efficient transfer of liquids and other substances. Made from durable material, it offers a reliable solution for a long service life. Easy installation and excellent sealing make it the ideal choice for industry professionals. Applications Food industry, dairies, breweries, beverage industry, chemical industry. Industries Food and beverage industry, chemical industry, pharmaceutical and biotechnology. Benefits The SMS female stem offers excellent sealing and durability, reducing the risk of leakage and improving safety. Its ease of use and durability make it an ideal choice for demanding industrial conditions. Chemical and corrosion resistance The connector is designed to withstand a variety of chemicals and prevent corrosion, which extends its service life and reduces maintenance costs. Sealing Suitable seals include EPDM and NBR seals, which ensure reliable sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The SMS female hose connector is designed to meet the highest hygiene standards in the food industry. This high-quality connector ensures the safe and efficient transfer of liquids and other substances. Made from durable material, it offers a reliable solution for a long service life. Easy installation and excellent sealing make it the ideal choice for industry professionals. Applications Food industry, dairies, breweries, beverage industry, chemical industry. Industries Food and beverage industry, chemical industry, pharmaceutical and biotechnology. Benefits The SMS female stem offers excellent sealing and durability, reducing the risk of leakage and improving safety. Its ease of use and durability make it an ideal choice for demanding industrial conditions. Chemical and corrosion resistance The connector is designed to withstand a variety of chemicals and prevent corrosion, which extends its service life and reduces maintenance costs. Sealing Suitable seals include EPDM and NBR seals, which ensure reliable sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The SMS female hose connector is designed to meet the highest hygiene standards in the food industry. This high-quality connector ensures the safe and efficient transfer of liquids and other substances. Made from durable material, it offers a reliable solution for a long service life. Easy installation and excellent sealing make it the ideal choice for industry professionals. Applications Food industry, dairies, breweries, beverage industry, chemical industry. Industries Food and beverage industry, chemical industry, pharmaceutical and biotechnology. Benefits The SMS female stem offers excellent sealing and durability, reducing the risk of leakage and improving safety. Its ease of use and durability make it an ideal choice for demanding industrial conditions. Chemical and corrosion resistance The connector is designed to withstand a variety of chemicals and prevent corrosion, which extends its service life and reduces maintenance costs. Sealing Suitable seals include EPDM and NBR seals, which ensure reliable sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The SMS female hose connector is designed to meet the highest hygiene standards in the food industry. This high-quality connector ensures the safe and efficient transfer of liquids and other substances. Made from durable material, it offers a reliable solution for a long service life. Easy installation and excellent sealing make it the ideal choice for industry professionals. Applications Food industry, dairies, breweries, beverage industry, chemical industry. Industries Food and beverage industry, chemical industry, pharmaceutical and biotechnology. Benefits The SMS female stem offers excellent sealing and durability, reducing the risk of leakage and improving safety. Its ease of use and durability make it an ideal choice for demanding industrial conditions. Chemical and corrosion resistance The connector is designed to withstand a variety of chemicals and prevent corrosion, which extends its service life and reduces maintenance costs. Sealing Suitable seals include EPDM and NBR seals, which ensure reliable sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The SMS female hose connector is designed to meet the highest hygiene standards in the food industry. This high-quality connector ensures the safe and efficient transfer of liquids and other substances. Made from durable material, it offers a reliable solution for a long service life. Easy installation and excellent sealing make it the ideal choice for industry professionals. Applications Food industry, dairies, breweries, beverage industry, chemical industry. Industries Food and beverage industry, chemical industry, pharmaceutical and biotechnology. Benefits The SMS female stem offers excellent sealing and durability, reducing the risk of leakage and improving safety. Its ease of use and durability make it an ideal choice for demanding industrial conditions. Chemical and corrosion resistance The connector is designed to withstand a variety of chemicals and prevent corrosion, which extends its service life and reduces maintenance costs. Sealing Suitable seals include EPDM and NBR seals, which ensure reliable sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The DIN 11851 male hose connector is a high-quality solution for demanding industrial applications, especially in the food and beverage industry. This connector is made of durable materials that guarantee longevity and efficiency in the transfer of liquids and other substances. It is designed with hygiene standards in mind, making it an excellent choice for applications requiring hygiene. Easy installation and excellent sealing make it a trusted choice for industry professionals. Applications Food industry, dairies, breweries, beverage industry, chemical industry. Industries Food and beverage industry, chemical industry, pharmaceutical and biotechnology. Benefits The DIN 11851 male stem food grade fitting offers excellent sealing and durability, reducing the risk of leakage and improving safety. Its ease of use and durability make it an ideal choice for demanding industrial conditions. Chemical and corrosion resistance The connector is designed to withstand a variety of chemicals and prevent corrosion, which extends its service life and reduces maintenance costs. Sealing Suitable seals include EPDM and NBR seals, which ensure reliable sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The food grade DIN 11851 female hose connector is designed specifically for the demanding needs of the food industry, providing a reliable and hygienic connection. This connector is made of high-quality materials that guarantee durability and longevity. Its precise design allows for easy installation and ensures a tight connection that prevents leaks and contamination. The food grade connector is compatible with a wide range of hoses and is ideal for transferring liquids. Applications Food industry, dairy processing, beverage industry, chemical industry Industries Food industry, beverage industry, chemical industry, pharmaceutical industry Benefits Provides excellent tightness and durability, reducing the risk of leakage and contamination. Easy to install and remove, making maintenance and replacement quick and efficient. Chemical and corrosion resistance Made of durable material that is highly resistant to a variety of chemicals and prevents corrosion, ensuring long service life and reliability. Sealing Silicone seals, EPDM seals. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The low pressure reducing nipple is designed for industrial requirements, providing a reliable connection in low pressure systems. Its durable construction ensures longevity and reduces the need for maintenance. Made from high-quality materials, the reducing nipple is suitable for a wide range of applications. Easy installation and compatibility with many hose types make it a versatile choice. Applications Compressed air systems, water systems, industrial process piping Industries Chemical industry, food industry, engineering industry Benefits The low pressure reducing nipple ensures a tight and secure connection, reducing the risk of leaks and improving system efficiency. Chemical and corrosion resistance Highly resistant to most common industrial chemicals and provides excellent protection against corrosion. Sealing The thread is sealed with Teflon tape or thread glue. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Chewing hose 0.7mm wall is a durable and transparent product, which is equipped with a metal spiral, which gives the hose additional strength and durability. Its wall thickness is 0.7 mm, and it offers good abrasion resistance and enables easy monitoring of liquid or air flow. Applications Chewing hose is designed for many different uses, including ventilation of industry, buildings and other premises and for transporting granular materials. It is also suitable as a hose for brush machines used in property maintenance, Industries Industry, construction, ventilation, cleaning. Benefits The chew hose offers excellent protection against fires and is highly resistant to oil and gasoline, making it useful for a wide variety of applications. Risks As a result of misuse or neglect of maintenance, the hose can become damaged or leak, emphasizing the importance of proper use and maintenance. Adapters The chewing hose is compatible with a wide variety of connectors, allowing it to be integrated into a wide variety of transfer systems. Chemical resistance The chew tube is designed to resist hydrolysis and microbes, making it a long-lasting choice. Operating temperatures The chewing hose has an operating temperature of -40 °C/+100 °C, so it is suitable for many different applications. Operating pressure classes The operating pressure class of the chewing hose is defined based on the use and explosion pressure class. Certificates and classes The chewing hose meets DIN 4102 B 1, ISO 8031 <109Ohm ja TRGS 727 <2,5108Ohm*m, ATEX 2014/34/EU ja DIN 26057 -standardit. Tutustu valikoimaamme ja pyydä tarjous jo tänään!

Here is a Chewing Hose with a 1.0mm wall, designed especially for industrial needs. It is the perfect solution for suction and blowing applications of consumables, offering a durable and versatile alternative. Applications The chewing hose is ideal for transporting lighter goods such as sawdust, dust and flour, as well as coarser material such as pellets, wood chips and grain. Industries Industry, construction, agriculture, wood processing. Property maintenance brush machines. Benefits This hose is very durable and long-lasting, maintaining its flexibility in varying temperatures (-40...+90 °C). Risks Improper use or maintenance can lead to damage to the hose and shorten its service life. Adapters The chew tube is compatible with several different connectors. Hoses Compatible with many different hoses. Chemical resistance The chewing hose is made to withstand various chemicals, offering reliability and longevity. Operating temperatures -40 - +90 Operating pressure classes 5 bar / 15 bar Certificates and classes DNV-GL, Bureau Veritas (BV), American Bureau of Shipping (ABS), EN 1474-II, EN 12434, EN 1474-III. We offer comprehensive advice on the selection of hoses, ensuring that you get a solution that suits your needs. Request a quote for Chewing Hose with 1.0mm wall today! Resistance

Chewing hose with a 0.6mm wall is a strong and durable choice for industrial needs. Its clear metal spiral reinforced construction makes it an ideal choice for transporting consumables and air. Applications Chemical industry, food industry, general industrial use. The transfer of grainy light materials and as an air conditioning hose. Industries Industry, chemical industry, food industry. Benefits The chew tube offers excellent resistance against wear and tear and its transparent structure allows you to follow the flow of liquid or air. Risks Improper use or maintenance can lead to hose damage and leaks. Chemical resistance The chewing hose is resistant to oil and gasoline, which increases its versatility. Operating temperatures -40 - +100 Operating pressure classes Information not available. Certificates and classes ISO 8031, TRGS 727, ATEX 2014/34/EU, BGI 739, DIN 26057. This chewing hose is designed to withstand the most demanding industrial conditions. Its reinforced structure and chemical resistance make it a reliable choice for a wide range of applications. Find out more and request an offer today!

Chewing hose 0.4mm wall is an industrial credit product that offers durability, reinforcement with a metal spiral and transparency for a wide range of needs. This hose is also suitable as an air conditioning hose and its operating temperature range is -40°C to +100°C. Applications Chemical industry, food industry, general industrial use. Destinations where consumables such as sawdust, glass, dust are moved Industries Chemical industry, food industry, general industrial use. Benefits Chew hose 0.4mm wall offers excellent wear resistance and meets fire safety standards, which makes it a safe and durable choice. Risks Misuse or poor maintenance can have harmful effects on the durability and functionality of the hose. Chemical resistance The chewing tube with a 0.4mm wall is designed to withstand hydrolysis and microbes, which guarantees its longevity. Operating temperatures Maintains its flexibility even at low temperatures. Operating pressure classes Chewing hose with a 0.4mm wall is designed to withstand the demanding pressure and suction conditions of industry. Certificates and classes ISO 8031, TRGS 727, ATEX 2014/34/EU, BGI 739, DIN 26057. This chewing hose is designed to meet the exact requirements of industry. Its reinforced structure and transparency make it a reliable choice for many applications. Contact us and request a quote today!