The HEL-Performance clutch hose offers a smooth and precise feel, making it an excellent choice for the Tema Motocross Enduro 2002- model. The hose's nylon coating ensures durability and protects it from wear, allowing it to maintain its performance for a long time.

The hoses are manufactured with meticulous attention to detail and 15 years of experience by a brake hose doctor at Porvoo. So you can rely on the craftsmanship of over 50,000 manufactured hoses with every braking action.

Model designation: - Seal of approval: - Layout: Note: When ordering this product you will receive factory-measured, fully assembled steel braided hoses. If you would like to create custom-measured hoses, you can do so. hereIf you need help choosing the right hose, you can get a quick answer from the brake hose doctor in the chat.

The HEL-Performance front brake hose is specially designed for the Tema Motocross / Enduro 2002- model. This top quality hose offers excellent braking feel and durability in demanding conditions. The nylon coating ensures longevity and protects the hose from wear. Whether you are riding off-road or on the road, this hose provides confidence and precision in braking.

The hoses are manufactured with meticulous attention to detail and 15 years of experience by a brake hose doctor at Porvoo. So you can rely on the craftsmanship of over 50,000 manufactured hoses with every braking action.

Model designation: - Seal of approval: EBE Layout: Similar to the original Note: When ordering this product you will receive factory-measured, fully assembled steel braided hoses. If you would like to create custom-measured hoses, you can do so. hereIf you need help choosing the right hose, you can get a quick answer from the brake hose doctor in the chat.HST external thread The reduction nipple is a high-quality and reliable connector with a cone in the thread. This acid-resistant product is designed to withstand the demanding conditions of industry. Applications HST external thread The reduction nipple is designed to be used especially in connection with the procurement and replacement of industrial hoses. Industries The product is suitable for all industries where durable and reliable connectors are needed, such as industry, construction and logistics. Benefits HST external thread Reduction nipple offers durability and reliability, which reduces the need for maintenance and replacement. Risks Improper use or maintenance can lead to connector damage, so proper use and maintenance is important. Adapters HST male thread The reduction nipple is compatible with many different hoses. Chemical resistance Acid-resistant HST external thread The reduction nipple is resistant to a wide variety of chemicals. Operating temperatures The operating temperature is -40 to +120 degrees. Operating pressure classes The working pressure class is 5 bar and the explosion pressure class is 15 bar. Contact us and request an offer for the HST external thread reduction nipple, which is a reliable and durable choice for all hose connection needs.

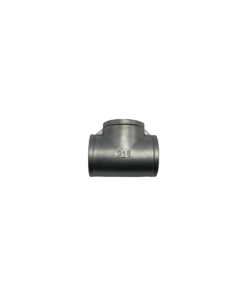

The HST T-connector with internal threads is designed to provide a reliable and long-lasting solution for industrial needs. Made of high-quality acid-resistant steel. Its internal thread profile ensures easy and tight installation, which reduces the risk of leaks and improves efficiency. The compact design allows for versatile use and easy integration into existing systems. Applications Pipeline connections, compressed air systems, water distribution networks, industrial process piping Industries Mechanical engineering, chemical industry, food industry, oil and gas industry Benefits The HST T-connector with internal threads offers excellent tightness and durability, minimizing the need for maintenance and improving system reliability. Chemical and corrosion resistance This connector is designed to withstand harsh chemical environments and prevent corrosion, extending its service life and reducing maintenance requirements. Sealing The connector is preferably sealed on the thread with thread sealant, which also lubricates the thread during the fastening phase, preventing it from seizing. Acid-resistant material requires an activator to accompany the thread sealant. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

HST reducing nipple male thread female thread is an acid-resistant connector that allows easy and efficient installation in industrial environments. Made of high-quality acid-resistant AISI 316 steel, it offers excellent resistance to corrosion, especially in demanding offshore conditions. The reducing nipple reduces maintenance and repair needs thanks to its reliable performance. The perfect choice for industrial professionals who value durability and longevity. Applications Offshore conditions, marine environments, industrial processes Industries Industry, shipping, oil and gas industry Benefits Durable construction reduces maintenance requirements, high performance in demanding conditions. Chemical and corrosion resistance The acid-resistant AISI 316 material protects the connector from corrosion and chemical damage, making it suitable for challenging environments. Sealing The connectors have a straight R thread, which requires Teflon tape, glue or hemp for sealing. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.