KRÄNZLE PROFI 195 TST 195BAR 230V 1400rpm

KRÄNZLE PROFI 175 TST 175BAR 400V 12L/MIN 1400rpm

Profi-jet b 13/150 150bar / 13l/min honda gx160lx

Pressure nozzle 25ast 1/6

High pressure gun starlet short

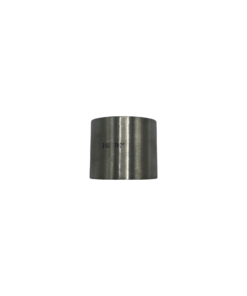

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar

• VLBS is forged from strong CrNiMo steel. • Simple and quick to weld. • High dynamic and static strength. • 100% distortion checked. • The welding piece is forged from the very weldable material S355J2+N (Fe52C) and equipped with a marking indicating the maximum load. The patented distance knobs create the air gap needed for welding. • Important: Thanks to the special seam (through-welded), it meets the requirements of DIN 18800. The root portion should be continuously welded. In this way, the root is corrosion-free. • The headset can be used outdoors. • Protected spring keeps the handle in the desired position and silent

Weldable lifting eye 3.2 ton. • Replaces flame-cut plate lugs • Can be loaded in all directions • Safety factor 4:1 • Rejuvenated and hardened, therefore very wear-resistant • Patented wear marks inside and outside • Rotating small weld