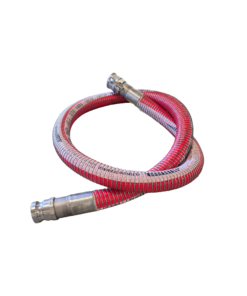

Composite hose 2" female saflok is designed to withstand demanding industrial conditions where reliability and chemical resistance are key. Its durable and flexible construction ensures easy connection and quick installation, making it an ideal choice for professionals. The hose is equipped with 2" camlock fittings, which allow for smooth connection to various systems. The Teflon inner surface ensures excellent chemical resistance, expanding the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Teflon coating inside the hose ensures excellent chemical resistance. Acid-resistant safety locking Saflok cam lever connector ensures the safety of the pressurized hose. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female saflok is designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. The durable and flexible construction makes it the perfect choice for professionals who value easy connection and quick installation. 2 inch camlock fittings ensure smooth connection to various systems. The Teflon inner surface ensures versatile chemical resistance, which increases the hose's application possibilities. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible construction makes handling and installation easy. Acid-resistant camlocks ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose has a Teflon membrane on the inside and acid-resistant connectors. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male female camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 2" male camlocks are designed for demanding industrial conditions where reliable chemical transfer is required. Made from high-quality materials, this hose combines durability and flexibility, making it an ideal choice for professionals. Its 2" camlock fittings allow for easy connection and quick installation. Thanks to the Teflon inner surface, the hose is resistant to a wide range of chemicals. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The lightweight and flexible design makes handling and installation easy. Quality components ensure reliability in demanding applications. Risks Incorrect pressure conditions can damage the hose, so it is important to follow the recommended usage instructions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance Resistant to many chemicals, making the hose a versatile industrial solution. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes The hoses are manufactured and tested to EN 13765 - IMO IBC code. The hose is delivered as a ready-to-use assembly, tested for stress. We give a one-year warranty on the assemblies.

Composite hose 3" male threads are designed for the demanding needs of industrial chemical transfer, offering excellent durability and versatility in various conditions. This hose is made of high-quality materials, ensuring long service life and reliable performance. The 3 inch composite hose with acid-resistant male threads is easy to connect and install, making it an ideal choice for industrial professionals. The Teflon inner surface of the hose provides a wide range of chemical resistance. Applications Liquid transportation, chemical transfer, industrial processes Industries Chemical industry, oil and gas industry, food industry Benefits The composite construction offers lightness and flexibility, making the hose easy to handle and install. The high-quality materials ensure excellent durability in demanding industrial environments. Risks Although the hose is designed to withstand a variety of chemicals, improper or excessive pressure can cause damage. It is important to ensure that the hose is installed correctly and used within the recommended operating conditions. Adapters Compatible with a wide range of industrial fittings, including camlock and flange fittings. Chemical resistance The hose is highly resistant to a wide range of chemicals, making it ideal for demanding industrial applications. Operating temperatures -30 - +100°C Operating pressure classes Working pressure 14 bar, Burst pressure 70 bar Certificates and classes Hoses are manufactured and tested according to EN 13765 - IMO IBC code.

Composite hose PTFE 14 bar LBS with flanges is a top-class product for transferring industrial chemicals. The hose is made of durable red composite with LBS flanges and a PTFE Teflon membrane that provides excellent chemical resistance. Applications Chemical transfer in industrial environments, high-pressure chemical transfer applications. Industries Chemical industry, industrial production and processing. Benefits Composite hose PTFE 14 bar LBS with flanges is very flexible and light, so it is easy to handle and install. It is also a very durable and reliable solution for transferring chemicals. Risks Improper use or maintenance of the hose can lead to chemical leaks and damage the hose. That is why it is important to follow the operating and maintenance instructions. Adapters Compatible with many different hose fittings. Hoses Compatible with many different connectors. Chemical resistance The PTFE Teflon film offers excellent chemical resistance. Operating temperatures -30°C to +100°C Operating pressure classes 14 bar / 70 bar Certificates and classes The product meets industry quality and safety standards. If you need a reliable and durable solution for transferring chemicals, ask for a quote on Composite hose PTFE 14 bar LBS flanges.

Teflon hose 5 bar is a durable and high-quality choice that offers reliability and longevity for industrial needs. The inner material of the hose is PTFE / Teflon and the outer material is PVC-coated polyester. The hose can withstand a pressure of 5 bar and its temperature range is -30 °C to +100 °C. Applications Teflon hose 5 bar is perfectly suited for use in petrochemicals, ports and ship to ship and ship to shore operations. Industries The hose is widely used in various industries, such as the petrochemical industry, ports and ships. Benefits Teflon hose 5 bar offers durability and reliability, which reduces maintenance and replacement needs. Risks Misuse or careless maintenance of the hose can lead to its damage. For this reason, it is important to observe proper use and maintenance. Adapters The Teflon hose 5 bar is compatible with various connectors, which allows it to be integrated into a wide range of systems. Chemical resistance Teflon hose 5 bar is made to withstand various chemicals, offering reliability and longevity. Certificates and classes The hose meets EN 13766: 2010, IMO, ICG codes. If you are looking for a durable and reliable hose for industrial needs, Teflon hose 5 bar is an excellent choice. Contact our experts and request a quote today!

Pp hose 5bar is an excellent choice for industrial hose needs. This product offers high performance, durability and flexibility that makes it an ideal choice for many industries. Applications PP hose 5bar is specially designed for oil, fuel, gasoline, paraffin and jet fuel transfers. Industries The product is an ideal choice for port operations, petrochemical processes and tank truck piping. Benefits PP hose 5bar offers excellent chemical resistance and longevity, which reduces the need for maintenance and replacement. Risks Improper use or maintenance can lead to hose damage and leaks, emphasizing the importance of proper use and maintenance. Adapters Pp hose 5bar is compatible with several standard connectors, which allows them to be integrated into a wide range of transfer systems. Chemical resistance Made to withstand the extreme conditions of chemicals, Pp hose 5bar offers reliability and longevity. Certificates and classes The product meets strict international standards and classifications. When you are looking for reliable hoses for industrial needs, contact our experts. We offer comprehensive advice on the selection of hoses, ensuring that you get a solution that suits your needs.

Multioil Composite hose 14 bar is specially designed for oil, fuel, petrol, paraffin and jet fuel. This blue hose combines versatility with excellent chemical resistance, making it an ideal solution for many industrial needs. Several sizes and colors are available, and our experts are happy to help you choose the right size. Applications: Ports, Petrochemical processes, Tankers. Industries: Oil and petrochemical industry, Transportation industry, Industrial service and maintenance. Benefits: Provides exceptional resistance to chemical agents, which extends the life of the hose. A versatile selection of sizes and colors enable customized solutions for different applications. Risks: As experts in composite hoses, we emphasize the importance of correct use and maintenance for the hoses' longevity. If used incorrectly or poorly maintained, the hoses can be damaged prematurely. Adapters: Compatible connectors available in different types and sizes, optimally fit Multioil composite hoses. Chemical resistance: Designed to withstand many chemicals, including oils and fuels, making it an ideal choice for demanding industrial applications. Certificates and classes: Meet industry standards and norms, more details available on request. Do you want to hear more or request an offer? Contact us via chat or call us - we'll be happy to help!

Multioil composite hose 10 bar is specially designed for oil, fuel, petrol, paraffin and jet fuel. This blue hose combines versatility with excellent chemical resistance, making it an ideal solution for many industrial needs. Several sizes and colors are available, and our experts are happy to help you choose the right size. Applications: Ports, Petrochemical processes, Tankers. Industries: Oil and petrochemical industry, Transportation industry, Industrial service and maintenance. Benefits: Provides exceptional resistance to chemical agents, which extends the life of the hose. A versatile selection of sizes and colors enable customized solutions for different applications. Risks: As experts in composite hoses, we emphasize the importance of correct use and maintenance for the hoses' longevity. If used incorrectly or poorly maintained, the hoses can be damaged prematurely. Adapters: Compatible connectors available in different types and sizes, optimally fit Multioil composite hoses. Chemical resistance: Designed to withstand many chemicals, including oils and fuels, making it an ideal choice for demanding industrial applications. Certificates and classes: Meet industry standards and norms, more details available on request. Do you want to hear more or request an offer? Contact us via chat or call us - we'll be happy to help!

Composite hose PTFE 14 bar is designed to withstand demanding industrial conditions. This high-quality hose with a PTFE inner membrane offers excellent pressure resistance and durability. The multi-layer construction ensures reliability and longevity, and it is compatible with a variety of standard connectors. This makes it an ideal choice for a variety of industries, such as the chemical and pharmaceutical industries and ports. Applications Chemical industry, food industry, pharmaceutical industry, oil and gas industry, offshore. Industries Chemical industry, food industry, pharmaceutical industry, oil and gas industry. Benefits Composite hose PTFE 14 bar offers excellent pressure resistance and longevity, making it a reliable choice for demanding conditions. The multi-layer construction ensures durability in various industrial applications. Risks An incorrectly installed or maintained hose can cause leaks and damage, so it is important to ensure proper installation and maintenance. Adapters Composite hose PTFE 14 bar is compatible with many standard connectors. Chemical resistance The PTFE inner membrane makes the hose highly resistant to various chemicals, such as acids and alkalis, as well as high temperatures. Certificates and classes Composite hose PTFE 14 bar meets industry standards: DNV, DNV PED, Bureau Veritas, Lloyd's Register of Shipping. Contact our experts and request a quote for this product.

Composite hose PTFE 10 bar is designed to withstand demanding industrial conditions. This red hose with a Teflon inner membrane offers excellent pressure resistance and durability. The multi-layer construction makes it a reliable choice for ports, ships and the chemical industry. Durability and reliability come together in this hose, which is compatible with a wide range of standard fittings. Applications Chemical industry, food industry, pharmaceutical industry, oil and gas industry, offshore. Industries Chemical industry, food industry, pharmaceutical industry, oil and gas industry. Benefits Composite hose PTFE 10 bar offers excellent pressure resistance and durability in demanding conditions. The multi-layer construction increases the hose's reliability and longevity. Risks An improperly used or maintained hose can cause damage and leaks, so proper use and maintenance is important. Adapters Composite hose PTFE 10 bar is compatible with several standard connectors. Chemical resistance The Teflon inner membrane makes the hose resistant to various chemicals, acids, bases and high temperatures. Certificates and classes Composite hose PTFE 10 bar meets industry standards: DNV, DNV PED, Bureu Veritas, Lloyds register of shipping. Contact our experts and request a quote for this product.

Composite hose green 14 bar is an excellent choice for handling oil, fuel, gasoline, paraffin and jet fuel. Thanks to its durable chemical structure, this hose is ideal for port use, petrochemical industry processes and as a hose for tanker trucks. With different colored composite hoses, you can easily distinguish between different applications, which increases safety and efficiency in the work environment. Green composite hose 10 bar offers reliability and durability in demanding industrial applications. Applications Ports, petrochemical processes, tankers. Industries Ports, petrochemicals, transport industry. Benefits Composite hose green 14 bar offers excellent chemical resistance and versatility, making it a good choice for many applications. The maximum manufacturing length is 30m. Risks Improper use or maintenance can lead to hose damage and leaks, so it is important to follow the instructions provided. Adapters Compatibility with a wide variety of fittings makes this hose a versatile choice. Chemical resistance Composite hose green 10 bar is designed to withstand various chemicals, which makes it a reliable choice. Certificates and classes Check product-specific information on certificates and categories. Contact our experts for more information or a quote for this product. We help you choose the solution that suits your needs.

Composite hose green 10 bar is the optimal solution for oil, fuel, gasoline, paraffin and jet fuel applications. This hose has excellent chemical resistance, making it particularly suitable for port use, petrochemical processes and as a hose for tanker trucks. Color-coded composite hoses make it easier to identify different applications and increase safety in the work environment. Green composite hose 10 bar is designed to withstand demanding operating conditions and provide reliable performance for a variety of industrial applications. Applications Ports, petrochemical processes, tankers. Industries Ports, petrochemicals, transport industry. Benefits Composite hose green 10 bar offers excellent chemical resistance and versatility, making it a good choice for many applications. The maximum length of our composite hose is 30m. Risks Improper use or maintenance can lead to hose damage and leaks, so it is important to follow the instructions provided. Adapters Compatibility with a wide variety of fittings makes this hose a versatile choice. Chemical resistance Composite hose green 10 bar is designed to withstand various chemicals, which makes it a reliable choice. Certificates and classes Check product-specific information on certificates and categories. Contact our experts for more information or a quote for this product. We help you choose the solution that suits your needs.

Composite hose chemical 14 bar black is an industrial credit product that is specially designed for the transfer of chemicals such as oil, fuel, gasoline, paraffin or jet fuel. It is particularly useful in ports, petrochemical processes and as a hose for tanker trucks. Applications Applications include ports, petrochemical processes and tanker trucks. Industries Industries include industry, petrochemical industry and logistics. Benefits The composite hose offers a reliable and durable solution for the transfer of chemicals. Its 10 bar pressure resistance makes it ideal for industrial use. Risks Always make sure that the hose is compatible with the chemicals used and take care of proper installation and storage. Adapters The hose is compatible with chemical hose connectors. Hoses The hose is compatible with various connectors suitable for the transfer of chemical substances. Chemical resistance Composite hose is designed for excellent chemical resistance, making it an ideal choice for transferring a wide range of chemicals. Operating temperatures The operating temperature range is -40 to +120. Operating pressure classes The operating pressure class is 10 bar and the explosion pressure class is 30 bar. Certificates and classes No applicable certifications or classes. Contact us and ask for an offer Composite hose chemical 10 bar black, designed especially for industrial needs.

Composite hose chemical 10 bar black is designed for the transfer of chemicals to withstand demanding industrial conditions. This black hose offers excellent performance and durability, especially when handling aggressive chemicals. The hose is designed to withstand an operating pressure of up to 10 bar, making it a reliable choice for a wide range of chemical transfer applications. Applications Transfer of chemicals, industrial process lines, loading and unloading of tankers. Industries Chemical industry, petrochemical industry, refineries, production plants. Benefits The hose offers high chemical resistance and a long service life, which reduces the need for maintenance and downtime. Risks Improper use or overuse can cause damage to the hose, which can lead to leaks or outages. Adapters Compatible with standard chemical fittings such as camlock and screw fittings. Chemical resistance Suitable for a wide range of chemicals including acids, bases and solvents. Operating temperatures -20°C to +80°C Operating pressure classes 10 bar / 30 bar Certificates and classes EN 13765, ISO 9001 Act quickly and ensure your chemical transfer is safe and efficient using this high quality composite hose. Request a quote today!

The compressed air lubricator is designed to provide high-quality, lubricated air for industrial applications. This mist lubricator improves the efficiency and reliability of compressed air equipment by using an oil mist. It is compatible with other Syntesi series compressed air service devices, allowing for versatile use. Wall brackets are available to order separately, making installation easier. Applications Industrial compressed air systems, machine shops, production lines Industries Metal industry, automotive industry, food industry Benefits A lubricator improves the performance and lifespan of compressed air equipment, reducing maintenance costs and improving production efficiency. Risks An incorrectly installed lubricator can cause malfunctions in the compressed air system. Regular inspection and maintenance are essential to ensure optimal operation.

A water separator for compressed air is an excellent solution when the goal is to produce high-quality, water-free air for industrial needs, such as painting or machine operation. This water separator is part of the Syntesi series and can be combined with other compressed air service devices from the same series. The water separator is designed to be easy to use and durable, and wall brackets are available to order separately. You can trust that this product will improve the quality and efficiency of your air system. Applications Painting, machine operation, industrial air systems Industries Industry, painting industry, engineering industry Benefits A water separator ensures that air systems operate efficiently and free of moisture, reducing equipment wear and tear and the need for repairs. It also improves the quality of painting and other processes by providing clean, dry air. Risks If the water separator is not used or maintained properly, it can lead to moisture accumulation in the air system, which can cause equipment damage and process disruptions. Chemical resistance The water separator is designed to withstand chemicals commonly used in industry, but it is recommended to check compatibility if necessary. Operating temperatures -10 - +50°C Operating pressure classes 0-12 bar

The threaded reducing fitting is a versatile and durable solution for industrial applications where a reduced thread is required. Made from high-quality brass, this fitting is ideal for handling compressed air, water and fuels. Its design allows for easy installation and reliable use in demanding conditions. This makes it an ideal choice for industrial professionals looking for an efficient and long-lasting fitting. Applications Compressed air, water, fuels Industries Industry, marine industry, engineering industry Benefits The threaded reduction fitting offers a reliable seal and a durable construction that reduces maintenance requirements. It is designed for long service life. Risks If installed incorrectly, the connector can cause leaks or pressure loss. It is important to ensure that the connector is installed correctly and is suitable for the application being used. Hoses Compatible with various compressed air and fuel hoses Chemical resistance The brass construction offers good resistance to many chemicals, but it is recommended to check compatibility individually. Operating temperatures -20 - +120°C Operating pressure classes 10bar / 25bar Certificates and classes No certificates mentioned