Chewing hose 1.4 mm wall is specially designed for suction and blowing applications of consumables. It offers a strong and professional solution for the transfer of coarse material such as wood chips, pellets and grain. It is also suitable as a hose for brush machines. Applications Chewing hose 1.4mm Seinämä is perfectly suited for transporting coarse material, such as transporting wood chips, pellets and grain. Industries Chewing hose 1.4mm Seinämä is the ideal choice for heavy and professional use in industrial applications, such as dryers and other professional environments. Benefits Chewing hose 1.4mm Seinämä offers reliable and durable performance even in demanding conditions. It is designed to withstand hydrolysis and microbes, which guarantees its long-term use. Risks Pu hose 1.4 mm The wall is designed to withstand demanding conditions. The more rigid structure of the hose, due to the thicker wall and stronger spiral, makes it very durable and suitable for professional use. Chemical resistance Chewing tube 1.4mm The wall is designed to withstand hydrolysis and microbes, which guarantees its long-term use. Operating temperatures The operating temperature of our hose is -40 °C/+100 °C, which makes it a versatile choice for various applications. Certificates and classes Our hose meets ISO 8031 <109Ohm ja TRGS 727 <2,5108Ohm*m standardit, mikä varmistaa sen sähköisen turvallisuuden. Lisäksi letkumme täyttää ATEX 2014/34/EU -standardin, mikä tekee siitä turvallisen valinnan monenlaisiin teollisuussovelluksiin.

Flexible rubber hose suitable for gas. Inner rubber: NBR Outer rubber: NBR / CR Reinforcement: Textile reinforced Safety factor: 3 Temperature: -25 °C/+80

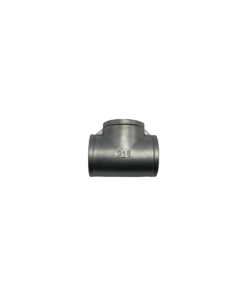

The HST T-connector with internal threads is designed to provide a reliable and long-lasting solution for industrial needs. Made of high-quality acid-resistant steel. Its internal thread profile ensures easy and tight installation, which reduces the risk of leaks and improves efficiency. The compact design allows for versatile use and easy integration into existing systems. Applications Pipeline connections, compressed air systems, water distribution networks, industrial process piping Industries Mechanical engineering, chemical industry, food industry, oil and gas industry Benefits The HST T-connector with internal threads offers excellent tightness and durability, minimizing the need for maintenance and improving system reliability. Chemical and corrosion resistance This connector is designed to withstand harsh chemical environments and prevent corrosion, extending its service life and reducing maintenance requirements. Sealing The connector is preferably sealed on the thread with thread sealant, which also lubricates the thread during the fastening phase, preventing it from seizing. Acid-resistant material requires an activator to accompany the thread sealant. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.