The brass hose connector with external thread is designed to provide a reliable and durable solution for industrial needs. Made from high-quality nickel-plated brass, this connector is ideal for handling compressed air, water and fuels. The straight-threaded design allows for easy and tight installation, and it is recommended to use tape, glue or hemp in the joints to ensure a tight seal. This connector is an ideal choice for industrial professionals looking for a durable and versatile connector. Applications Compressed air, water, fuels Industries Industry, construction, energy sector Benefits Durable and corrosion-resistant material ensures long-lasting use. Easy installation thanks to the straight-threaded design. Chemical and corrosion resistance Nickel-plated brass offers excellent resistance to a variety of industrial chemicals and corrosion. Sealing Recommended sealing methods: tape, glue, hemp Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below.

Hose connector with mm thread is designed to provide a reliable and durable solution for industrial needs. Made of high-quality brass, this connector is ideal for various hose connections and ensures a tight and safe connection. Easy installation and versatility make it an ideal choice for industrial professionals who value efficiency and reliability. When installing the connector, it is recommended to use tape, glue or hemp to ensure a perfect seal. Applications Industrial piping, hydraulic systems, compressed air lines, water supply systems Industries Mechanical engineering, chemical industry, food industry, construction industry Benefits Brass hose connector offers excellent corrosion resistance and long service life. It is easy to install and maintain, saving time and cost. Risks The tightness of the hose connection may deteriorate over time if proper sealing materials are not used during installation. This can lead to leaks and reduced system performance. Hoses Compatible hoses include PVC hoses, rubber hoses and polyurethane hoses. Chemical resistance Brass is highly resistant to most industrial chemicals, but it is worth checking compatibility, especially with aggressive substances. Operating temperatures -20 to +80°C Operating pressure classes 6bar / 18bar

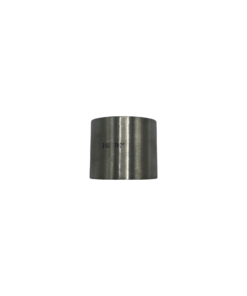

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar