Nlp spherical plain bearing housing is designed to protect and support spherical plain bearings, ensuring their longevity and efficiency. Made of durable cast iron or steel, it protects the bearings from dust and dirt, while promoting heat dissipation. This component is a key part of a wide range of industrial applications, such as electric motors and gearboxes. It ensures the smooth and uninterrupted operation of your equipment. Applications Electric motors, gearboxes, hydraulic cylinders, industrial machinery Industries Industry, mechanical engineering, automation, energy industry Benefits The NLP spherical plain bearing housing extends bearing life and improves performance. It protects bearings from contaminants and helps control temperature. Risks Without the right spherical plain bearing housing, bearings can be subject to excessive wear and overheating, which can lead to equipment malfunctions. Contamination can also significantly shorten the life of bearings.

The GE spherical plain bearing is a high-quality solution for industrial applications, designed to withstand radial loads and misalignment. Its unique design provides a sliding alignment surface, making it an excellent choice for heavy static and variable loads. The bearing requires lubrication and has a lubrication groove on its outer ring for this purpose. This spherical plain bearing provides reliability and performance for demanding industrial applications. Applications Industrial equipment, mechanical engineering, heavy loads, compensation of alignment errors Industries Engineering industry, heavy industry, manufacturing industry, mining industry Benefits GE spherical plain bearings are highly resistant to heavy loads and misalignment, which extends the life of equipment and reduces the need for maintenance. Risks Insufficient lubrication can lead to premature wear, and if installed incorrectly, the bearing may not function optimally. Chemical resistance The GE spherical plain bearing offers good resistance to a wide range of industrial chemicals, making it a reliable choice for demanding environments.

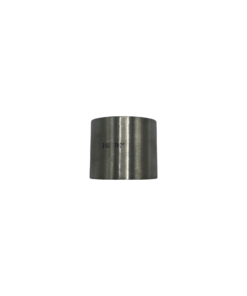

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar