The washing gun used in food washing with 1/2" internal thread 24 bar is precisely designed for industrial washing needs. This washing gun is created to withstand demanding conditions, and it offers a water flow of 24 liters per minute at a pressure of 5 bar. Applications Food industry, washrooms, industrial cleaning operations. Industries Food industry, industrial cleaning, industrial maintenance. Benefits Using a washing gun makes cleaning processes more efficient and saves time. It is also durable and reliable, which reduces the need for maintenance. Risks Misuse or careless handling can result in damage to the gun or malfunction. Chemical resistance The washing gun is designed to withstand strong detergents and chemicals, which guarantees longevity and reliability. Operating temperatures -10 - +60 Operating pressure classes 5 bar / 24 bar When you need a reliable and durable solution for industrial washing needs, ask for a quote for this washing gun. Our experts will be happy to help you find the right solution for your needs.

Shower pipe 150l/min 25mm hose reel with adjustable shower nozzle.

Shower pipe 75/min 19mm hose reel with adjustable short shower nozzle

Wash-bear 80l/min 25mm hose reel with adjustable shower nozzle.

Washing bear 60l/min with 19mm hose reel with adjustable spray nozzle.

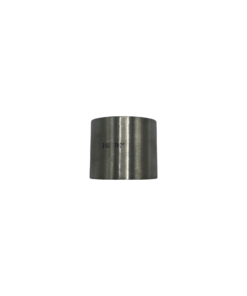

The HST reducing sleeve is designed for efficient and reliable reduction of pipes and hoses in demanding industrial environments. Made from high quality Aisi 316 steel, it offers excellent durability and longevity. The reducing sleeve is perfect for joining hoses when a tight and secure connection is required. Easy to install, it improves system performance and reduces maintenance. Applications hose connections, industrial piping, cooling and heating systems Industries chemical industry, energy industry, food industry, water supply, maritime industry Benefits The HST reducing sleeve provides a secure and tight connection, reducing the risk of leaks and improving system safety. Risks If installed incorrectly, the reducing sleeve can cause leaks or damage the hoses. It is important to follow the manufacturer's instructions to ensure perfect operation. Chemical resistance Resistant to most industrial chemicals, but it is recommended to verify compatibility with specific substances before use. Operating temperatures -20 - +100°C Operating pressure classes 10 bar / 30 bar

The HST coupling is a high-quality and durable product, designed specifically for demanding industrial conditions. Its acid-resistant construction makes it easy and hassle-free to purchase, replace and handle hoses. Available in a variety of sizes, the HST coupling offers a solution that suits your needs. This product is a reliable choice that will stand the test of time and hard use. Applications Industrial applications where durability and acid resistance are required. Industries Chemical industry, metal industry, construction industry. Benefits The HST coupling simplifies the hose handling process and offers excellent durability. Its acid resistance ensures longevity in demanding conditions. Risks Careless handling or incorrect use can damage the sleeve. It is important to follow the instructions for use and ensure regular maintenance. Chemical resistance High-quality materials ensure excellent resistance to various chemicals. Operating temperatures -40 - +120°C Operating pressure classes 5 bar / 15 bar