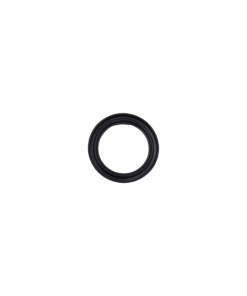

The Tri-clamp seal is an industrial quality product that offers a reliable and durable solution for connecting hoses. The seal is made of food grade rubber. Applications The seal is well suited for foodstuffs and detergents. Industries Food industry, chemical industry, pharmaceutical industry, cosmetics industry, biotechnology. Benefits Tri clamp seals offer reliability and longevity, reducing the need for maintenance and improving production efficiency. Risks Improper installation or maintenance of seals can lead to leaks or other problems. That is why it is important to follow the installation instructions and take care of regular maintenance. Chemical resistance Food-grade rubber is resistant to a wide variety of chemicals, which makes the seal versatile in various industries. Operating temperatures EPDM -40 to +120 NBR -40 to +80 Operating pressure classes 5 bar / 15 bar Contact us to get a quote for the Tri-clamp seal or if you need more information about the product.

The Tri Clamp SMS conversion fitting is designed to provide an easy-to-use and reliable solution for industrial applications. It combines the Tri Clamp and SMS standards, allowing for versatile use in various applications. This fitting is particularly suitable for low-pressure systems where quick and tool-free connection is required. Its high-quality construction ensures durability and longevity. Applications Low-pressure systems in the food industry, process industry applications, beverage industry piping. Industries Food industry, beverage industry, chemical industry. Benefits Quick installation and removal without tools saves time and reduces downtime. Versatile compatibility enables use in different systems. Chemical and corrosion resistance The Tri clamp SMS conversion connector is highly resistant to a wide range of chemicals and is designed to provide long-lasting protection against corrosion. Sealing Compatible with SMS and Tri clamp seals. Finding the right size By measuring the outer or inner diameter of the thread with a caliper, you can easily check the correct connector size using the thread table below. Our welding service helps with all connector applications.