Rubber hoses are a critical component in the food industry, as they ensure that products move safely and hygienically from one production line to the next. The correct selection and maintenance of these hoses is essential to maintain the quality and safety of food. In this article, we discuss what should be taken into account when choosing and using rubber hoses so that they meet the strict requirements of the food industry, and at the end you will find food-approved hoses and connectors available through us.

Rubber hoses for food use

Rubber hoses designed for food use are specially manufactured and meet strict hygiene and safety requirements. These hoses are made of material that does not leak harmful substances into food and are resistant to high temperatures and chemicals common in the food industry. Rubber hoses are a common choice due to their flexibility and durability, but there are also other materials on the market such as plastic and PTFEeh.

Although rubber hoses are widely used, there are also other options for food use. Plastic hoses, especially PVC and polyurethane hoses, offer excellent flexibility and lightness, which makes them easy to handle and install. PTFEhoses (polytetrafluoroethylene), on the other hand, are an excellent alternative for chemically aggressive environments, as they withstand almost all chemicals and extreme temperatures.

Rubber hoses are an excellent choice when durability and flexibility are needed, but plastic hoses and PTFE hoses may be better options in certain applications, such as chemically demanding environments or when a special level of hygiene is required. The choice of these materials always depends on the intended use and which properties are critical in that application.

Rubber hose materials in the food industry

Rubber hoses used in the food industry are usually made of natural rubber, EPDM rubber or silicone rubber. Natural rubber offers excellent flexibility and durability, but it does not always withstand chemicals and high temperatures as well as synthetic alternatives. EPDM rubber is a popular choice because it is highly resistant to acids, alkalis and temperature fluctuations. Silicone rubber, on the other hand, is an excellent choice when extreme heat resistance and flexibility are needed.

While rubber is a common material, plastic hoses offer a lighter alternative that is often more affordable and easier to install. PVC hoses are very popular due to their flexibility and chemical resistance, while Polyurethane hoses offer better wear resistance. PTFE hoses, on the other hand, can withstand a wider range of temperatures and chemicals than most rubber hoses.

When choosing a hose material for the food industry, it is important to take into account the ability of the material in question to withstand the required chemicals, temperatures and pressures. Choosing the right material ensures smooth production and food safety, which is critical in this kind of environment.

Hygiene and safety of the rubber hose

Rubber hoses intended for food use must meet strict hygiene and safety requirements. These hoses are made of materials that do not leak harmful substances into food and are easy to clean. They withstand repeated sterilization without deterioration of their material properties, making them ideal choices for the food industry. Rubber hoses, such as EPDM and silicone hose, are excellent choices, but PTFE hoses also have significant advantages, especially in terms of hygiene.

PTFE tubing is practically non-stick, which makes it very easy to clean and sterilize. This feature is especially important in the food industry, where hygiene is of primary importance. In addition, PTFE is resistant to almost all chemicals, ensuring that the hose remains safe and clean even when used in highly aggressive environments.

Plastic hoses such as PVC and polyurethane, also offer good hygiene and safety, but they do not always withstand repeated sterilization as well as PTFE or silicone rubber. Therefore, choosing the right hose material largely depends on the application and how often and how the hoses need to be cleaned.

Operating conditions and durability

Rubber hoses intended for food use are exposed to varying temperatures, pressure and chemicals. For example, EPDM rubber is highly resistant to temperature fluctuations and chemical exposures, which makes it a good choice for a wide range of applications. Silicone rubber is particularly good at high temperatures, so it is well suited for processes where the hose is exposed to hot steam or boiling water.

Plastic hoses, such as PVC and polyurethane hoses, are lightweight and flexible, making them excellent choices for applications that require easy handling and installation. However, they do not always withstand extreme temperatures or chemicals as well as rubber hoses.

PTFE hoses, on the other hand, are known for their exceptional durability in almost all chemical environments and temperatures, which makes them an ideal choice for challenging conditions.

To ensure durability, it is important to choose the right hose material for the application and ensure that the hose is designed to withstand the conditions in question. A well-chosen and well-maintained hose extends the life of the device and improves the efficiency of production processes.

Operating conditions and durability

All rubber hoses in the food industry are exposed to varying temperatures, pressure and chemicals. For example, EPDM rubber is highly resistant to temperature fluctuations and chemical exposures, which makes it a good choice for a wide range of applications. Silicone rubber is particularly good at high temperatures, so it is well suited for processes where the hose is exposed to hot steam or boiling water.

Plastic hoses, such as PVC and polyurethane hoses, are lightweight and flexible, making them excellent choices for applications that require easy handling and installation. However, they do not always withstand extreme temperatures or chemicals as well as rubber hoses. PTFE hoses, on the other hand, are known for their exceptional durability in almost all chemical environments and temperatures, which makes them an ideal choice for challenging conditions.

To ensure durability, it is important to choose the right hose material for the application and ensure that the hose is designed to withstand the conditions in question. A well-chosen and well-maintained hose extends the life of the device and improves the efficiency of production processes.

Rubber hose maintenance and replacement

Regular maintenance and inspection of hoses are essential in the food industry, as rubber hoses can wear and deteriorate over time. Hoses should be checked regularly for cracks, leaks and other damage and should be replaced immediately if signs of wear appear. A properly maintained rubber hose can last for years, but neglecting maintenance can lead to production interruptions and jeopardize food safety.

Plastic hoses, such as PVC and polyurethane, generally require less maintenance than rubber hoses, but may wear out more quickly, especially if used in extreme conditions. PTFE hoses, on the other hand, are very durable and require little maintenance, which makes them cost-effective in the long run. However, regular inspection of PTFE hoses is also important, especially when they are exposed to heavy wear.

Proper storage and handling of hoses are also important factors that affect their durability. Hoses should be stored in a dry and cool environment, protected from direct sunlight and chemicals that could prematurely weaken the material.

General standards and certificates

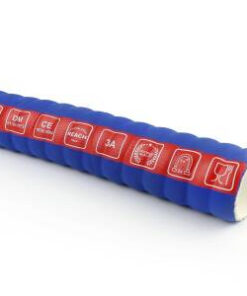

Rubber hoses intended for food use must meet several standards and certificates, such as FDA, EU 1935/2004, and EN 1186. These standards ensure that the hoses are safe to use with food and do not leak harmful substances into food. Rubber hoses such as EPDM and silicone are often FDA approved, making them a reliable choice for the food industry.

Plastic hoses such as PVC and polyurethane can also meet the same strict standards, but must be specially made for food use. PTFE hoses easily meet all strict hygiene and safety requirements, which makes them a generally accepted option in the food industry.

When searching for rubber hoses for food use, it is important to ensure that the hose meets all applicable standards and certifications. This ensures that the hose meets the required levels of hygiene and safety, and that it is safe to use in that application.