We work

Thread measurement instructions

Measuring threads is a key skill, especially for maintenance and service professionals. Finding and identifying the correct thread ensures that parts fit together without time-consuming repairs or incorrect connections, reducing downtime and improving safety.

This guide goes over the key tools and methods to help you determine the exact size and type of thread. In addition, we offer a downloadable thread table designed for Finnish industrial professionals to speed up identification work and ensure compatible parts.

Push gauge: Simple and reliable gauge for basic measurement

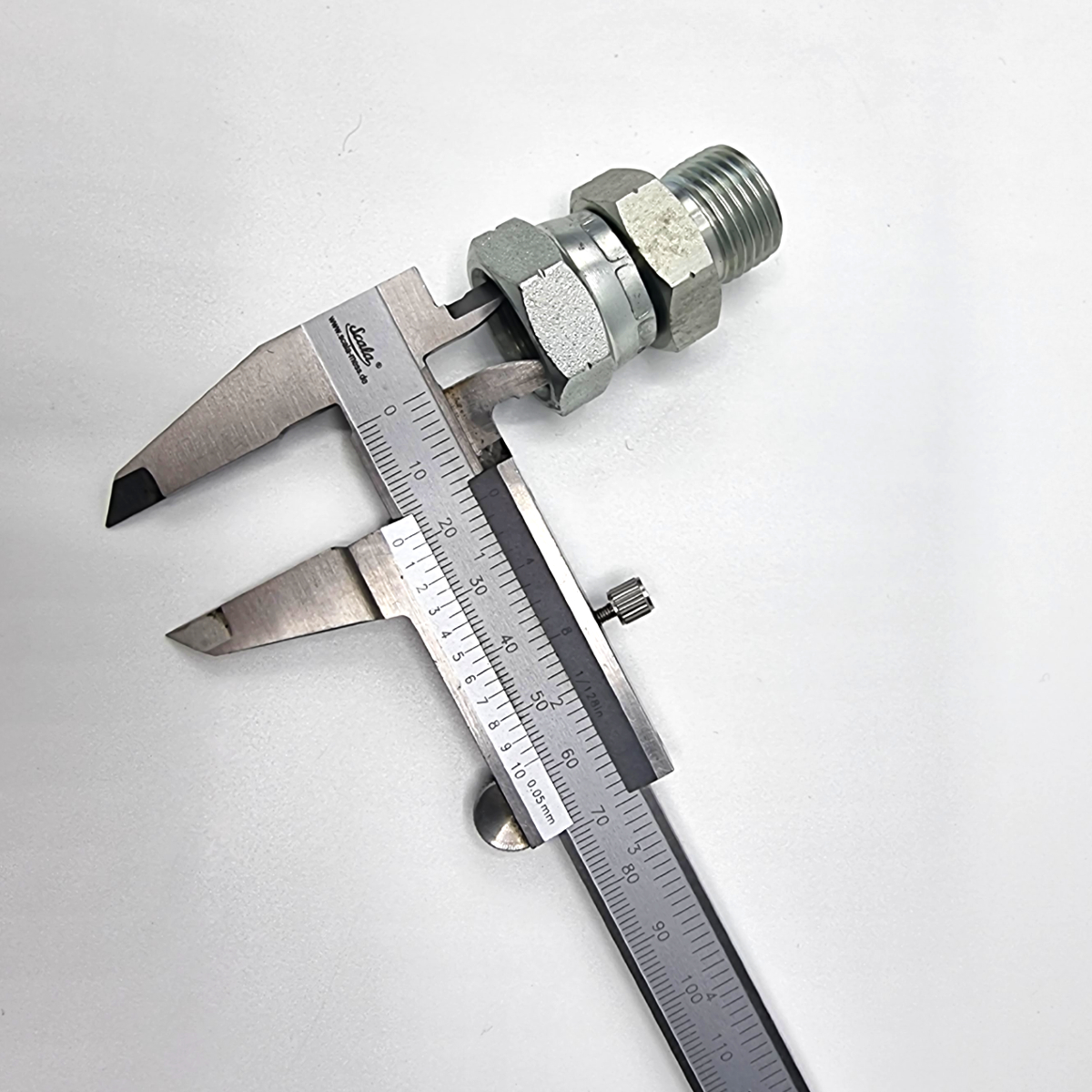

A push gauge is a familiar and easy-to-use tool for many industry professionals, and it also works reliably when measuring the diameter of a thread. The caliper can be used to measure both the outer and inner diameter, which gives a first idea of the size of the thread. A caliper is especially useful when you're assessing whether it's the right size before using more precise tools. It is accurate enough for most applications and especially handy in field conditions where speed is of the essence. This will reduce the risk of using the wrong type of thread and ensure that the replacement parts fit perfectly.

Thread comb: Precision tool for thread pitch measurement

Once the diameter is known, the spiral comb is the next step for a more accurate measurement. A spiral comb is a special tool that has many serrated plates with different pitches. They allow you to accurately measure the pitch of the thread by comparing the thread to the saw blade in the comb. The pitch determines how many revolutions the thread advances per millimeter (metric thread) or inch (inch thread). For example, the marking 10×1 means that the diameter of the thread is 10 mm and the pitch is 1 mm. A thread comb is an especially valuable tool when you need to identify the exact type of thread from among many options, reducing the risk of errors and ensuring the durability of the joints.

Metric and inch threads - identifying the right type

Identifying the type of thread—whether it's metric or inch—is a critical step in maintenance work, especially when working with multinational equipment. In Europe, metric threads are more common, while devices from the United States may have inch threads. This information can save time and money in purchasing spare parts and prevent errors in fitting parts. Metric threads are usually straightforward to identify, but inch threads can have more variation, requiring accurate measurement and the use of the correct charts. Choosing the wrong thread can cause unnecessary costs and delay the work, so identification is an essential step.

Special threads for different uses: taper and sealing threads

During maintenance, you may come across special threads, such as conical threads, which are used especially in compressed air and water piping systems to guarantee tightness without a separate seal. One of the most well-known taper threads is NPT (National Pipe Thread), which is common in North America and is often found in systems where a tight and reliable connection is required. In such cases, accurate identification and use of the correct thread is particularly important to avoid leaks and malfunctions. Special threads are also used in various connection points where special fastening or sealing properties are required, and their selection is key in, for example, hydraulics and pneumatics.

Thread table: a fast and reliable tool for identification

Thread tables are an excellent tool when you need quick confirmation of thread size and pitch. They provide detailed dimensions and characteristics of the most common threads, so you can easily find the right option among the standards in use. Maintenance and service in industry is often busy, and spiral tables can save considerable time. With the help of tables, you can make sure that the parts you choose fit together perfectly and that the work goes quickly and smoothly without any extra mistakes or corrections.

Downloadable Thread Chart - Designed for Professionals

The downloadable thread table available on our website is tailored for use by professionals. This free chart includes the most common threads in use in both metric and inch sizes and is clear and easy to use. The table is especially suitable for field conditions and quick checks when you need information immediately. This way you can be sure that you are using the correct threads and avoid possible fitting problems. The spiral table serves as a practical support when the work requires precision and quick decision-making.

Summary

Measuring threads and choosing the right thread are an essential part of maintenance and service tasks. By measuring and identifying the thread correctly, the durability of the connections, the functionality of the systems and a long service life can be ensured. The right tools, such as a feeler gauge, thread comb and thread tables, make this process easier and increase the efficiency of the work. We hope that this instruction and the downloadable thread table will help you to do your work quickly and accurately, which will reduce the risk of mistakes and improve the quality of your work.

Author

Toni Mielikainen

CEO

Mittaletku

+358 400 292 874

[email protected]

Linkedin

Toni is perhaps Finland's most experienced hose master, whose hands have passed through hundreds of solutions for all domestic industries. More than 20 years of experience in hose and connector matters can be seen as expertise that both large production plants and small breweries benefit from.